Bacterium-restraining haydite and preparation method thereof

A ceramsite and particle size technology, applied in the field of bacteriostatic agents and their preparation, can solve the problems of poor safety, easy decomposition, short service life, and difficulty in popularization and application of organic antibacterial agents, and achieve easy decomposition, increase redox potential, The effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

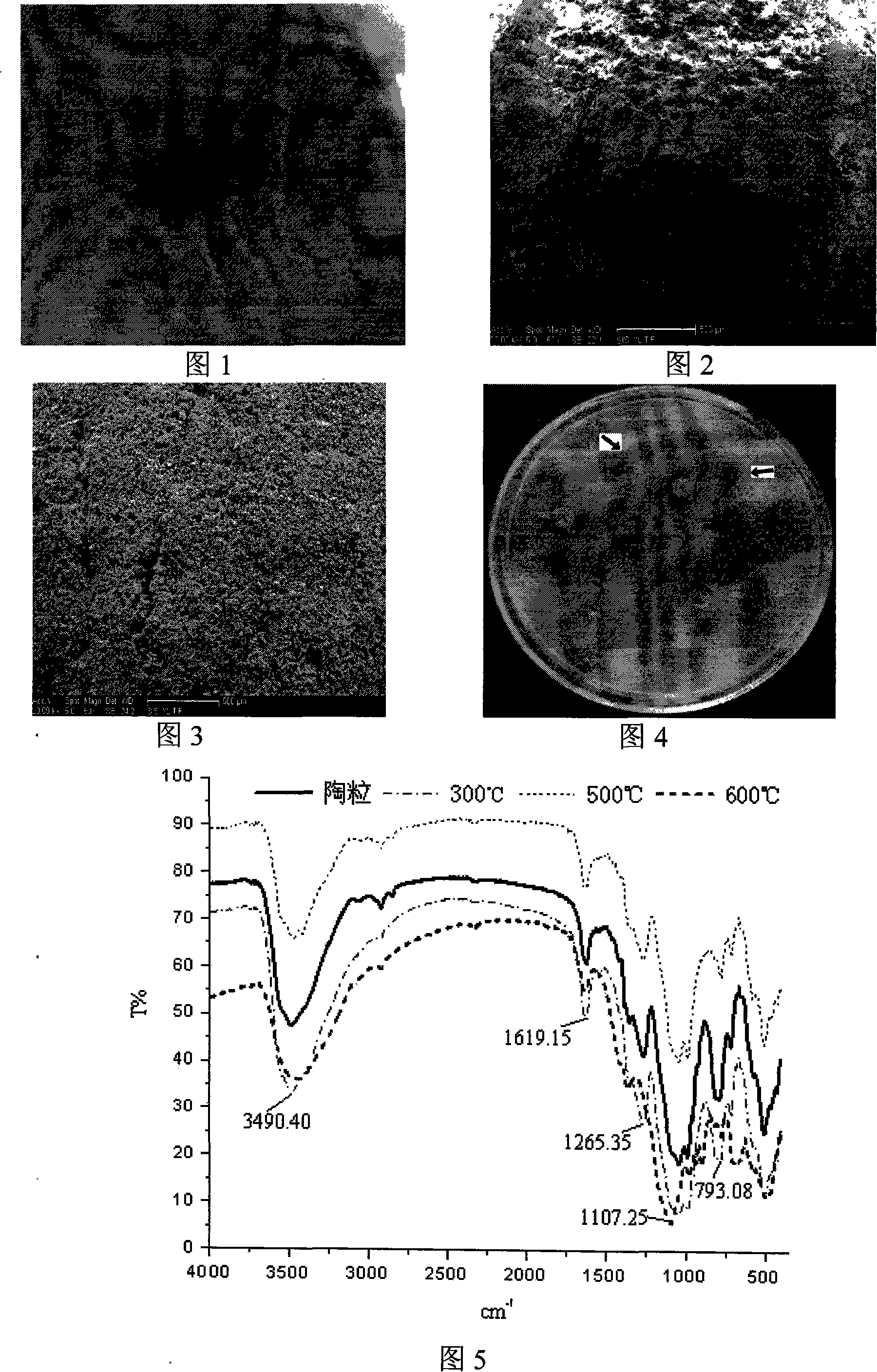

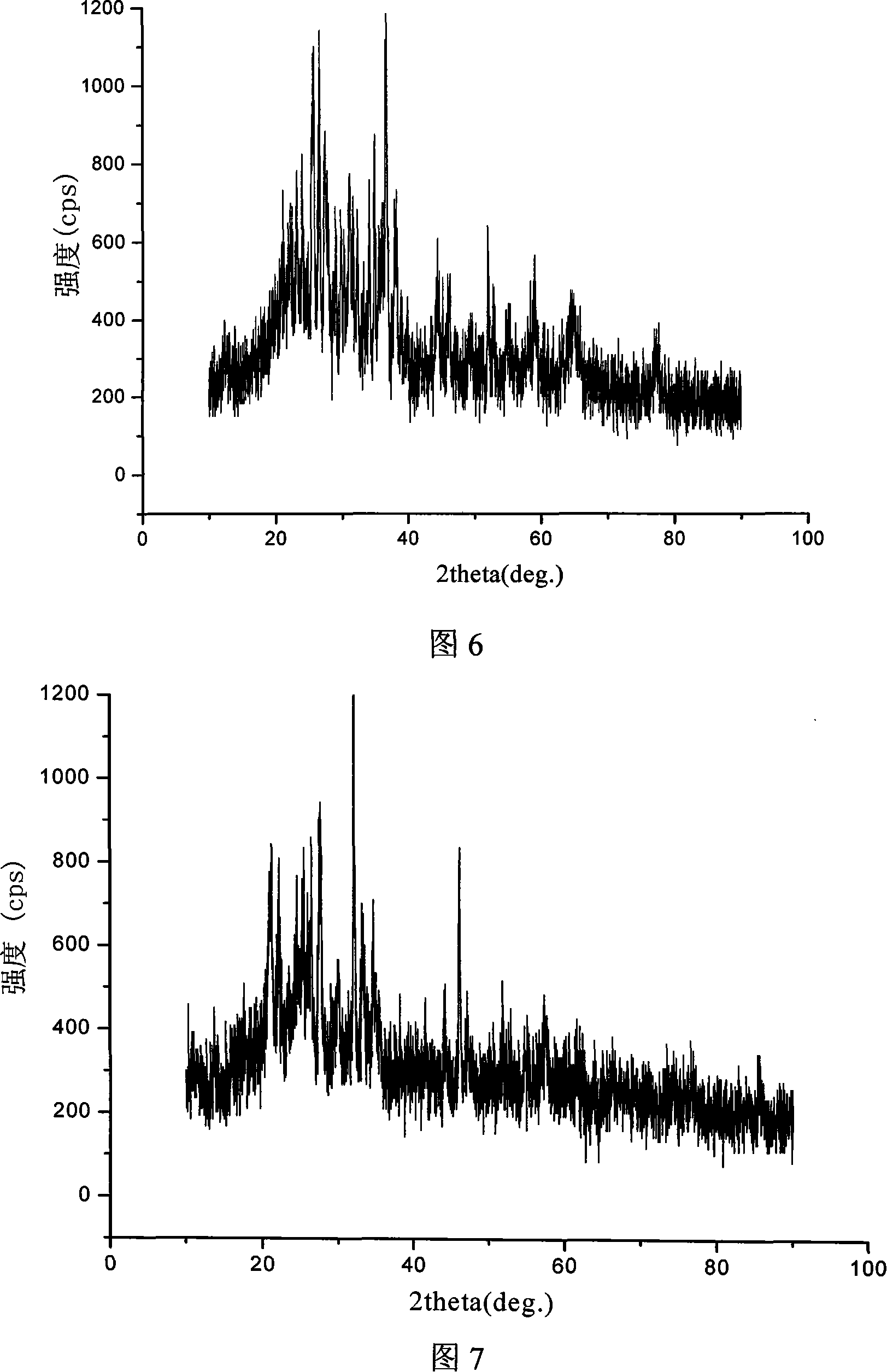

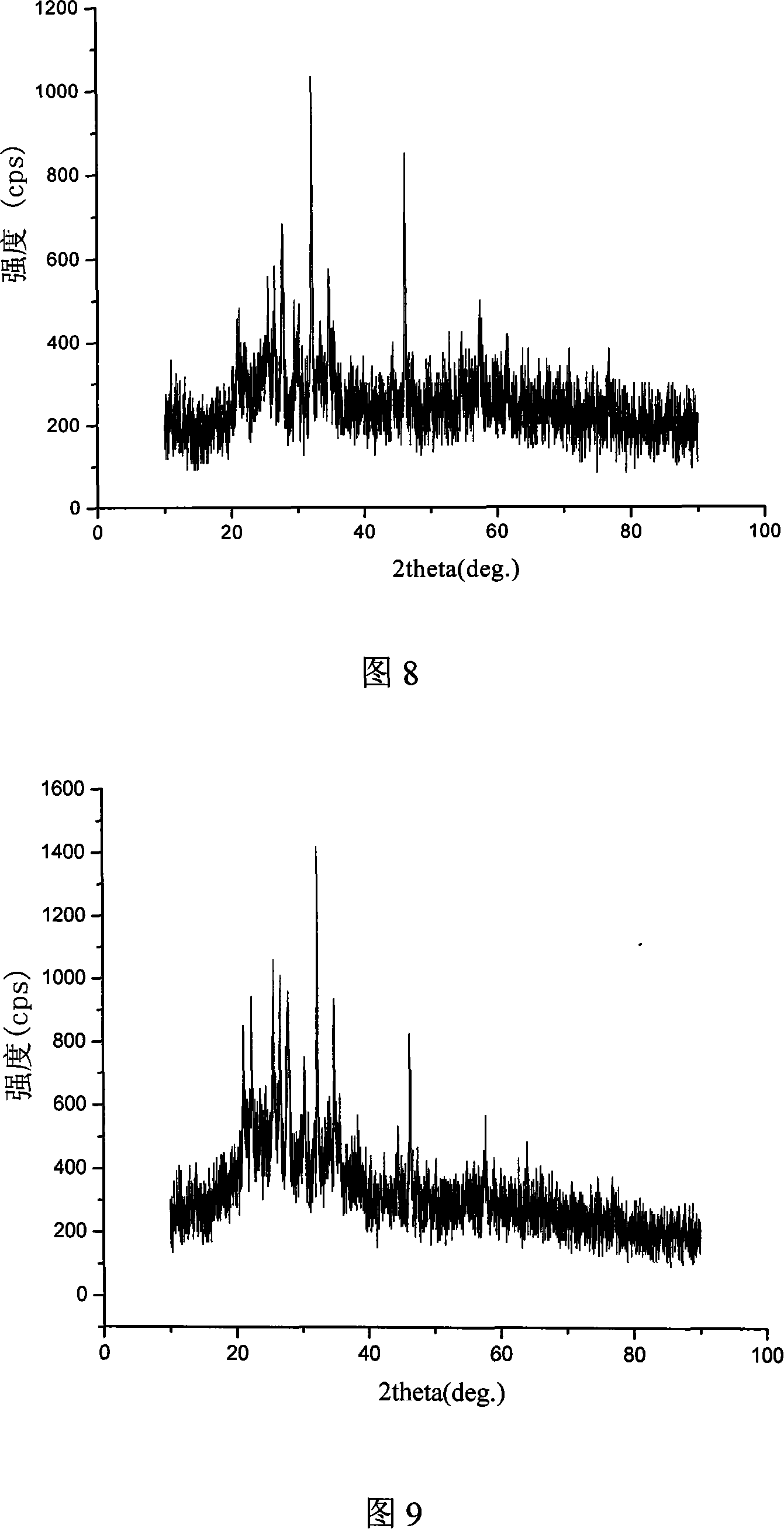

Image

Examples

specific Embodiment approach 1

[0013] Specific embodiment one: In the present embodiment, the antibacterial ceramsite is composed of 30 to 80 parts of carrier, 2 to 6 parts of molybdate, 0.01 to 2 parts of silver salt, and 0.01 to 2 parts of copper salt in parts by weight. 2-6 parts of nano-ZnO, 6-10 parts of sludge powder with a particle size of 0.05-1.0 mm, 3-8 parts of pore-forming agent, 0.08-2 parts of binder and 10-20 parts of glaze-forming agent Made by mixing, drying, grinding, calcining and regrinding.

[0014] The carrier is composed of 50-800nm (nanometer or submicron) tourmaline, zeolite and shale with a particle size of 0.1-30 μm, and the mass ratio of tourmaline, zeolite and shale is 4-8:1-4: 1. Described molybdate is ammonium molybdate. Described silver salt is silver sulfate or silver chloride. Described copper salt is copper sulfate or copper nitrate. The pore forming agent is CS. The binder is SF. The glaze-forming agent is a low-temperature glaze.

[0015] The sludge powder is ob...

specific Embodiment approach 2

[0017] Specific embodiment two: the difference between this embodiment and specific embodiment one is that antibacterial ceramsite is composed of 35 to 65 parts of carrier, 3 to 5 parts of molybdate, 0.1 to 1 part of silver salt, 0.1 parts by weight of antibacterial ceramsite ~1 part of copper salt, 3~5 parts of nano ZnO, 7~9 parts of sludge powder with a particle size of 0.05~1.0mm, 4~6 parts of pore forming agent, 0.1~1.5 parts of binder and 12 ~18 parts of glazing agent are prepared by mixing, drying, grinding, calcining and regrinding. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0018]Specific embodiment three: the difference between this embodiment and specific embodiment one is that the antibacterial ceramsite is composed of 50 parts of carrier, 4 parts of molybdate, 0.5 part of silver salt, 0.5 part of copper salt, 4 parts by weight. It is prepared by mixing, drying, grinding, calcining and regrinding of 1 part of nano-ZnO, 8 parts of sludge powder with a particle size of 0.05-1.0mm, 5 parts of pore forming agent, 1 part of binder and 15 parts of glaze forming agent. . Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com