Composition for holographic recording medium, holographic recording medium, and method for producing the same

A technology of holographic recording medium and composition, which is applied in the directions of recording information storage, recording/reproducing by optical method, data recording, etc., can solve the problem of not proposing the implementation of holographic optical recording medium, etc., and achieve the effect of high-density recording

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0228] In order to adjust the conditions of irradiation with ultraviolet rays, an ultraviolet absorber may be added to the cholesteric liquid crystal layer. The ultraviolet absorber is not particularly limited, and may be appropriately selected according to the intended application. Preferred examples thereof include benzophenone ultraviolet absorbers, benzotriazole ultraviolet absorbers, salicylic acid ultraviolet absorbers, cyanoacrylate ultraviolet absorbers, and oxalanilide ultraviolet absorbers. Specific examples of these ultraviolet absorbers are described in, for example, the following patent documents: Japanese Patent Application Laid-Open (JP-A) 47-10537, JP-A 58-111942, JP-A 58-212844, JP-A 59-19945, JP-A -A 59-46646, JP-A 59-109055, JP-A 63-53544, Japanese Patent Application Publication (JP-B) 36-10466, 42-26187, 48-30492, 48-31255, 48-41572, 48 - 54965, 50-10726, US Patent 2,719,086, US Patent 3,707,375, US Patent 3,754,919 and US Patent 4,220,711.

[0229] The t...

no. 1 approach

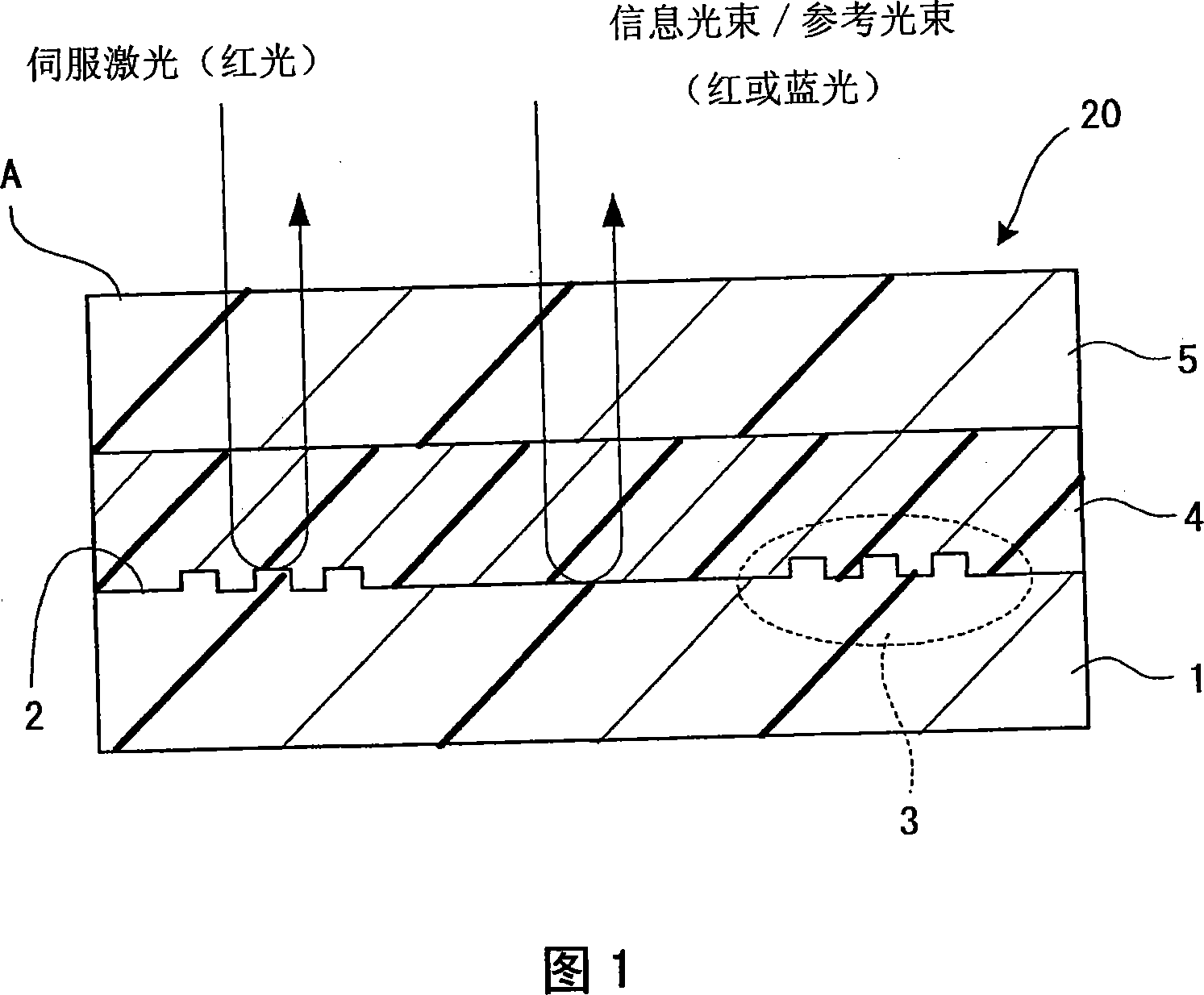

[0241] 6 is a schematic cross-sectional view of the structure of the hologram recording medium according to the first embodiment of the present invention. In the hologram recording medium 21 according to the first embodiment of the present invention, the servo pit pattern 3 is formed on the polycarbonate resin substrate or the glass substrate 1, and the servo pits are coated by using aluminum, gold, platinum, or the like Pattern surface, reflective surface 2 is formed on the servo pit pattern. In FIG. 6 , a servo pit pattern is formed on the entire surface of the second substrate 1 . The servo pit pattern 3 may be periodically formed as shown in FIG. 1 . The height of the servo pit pattern 3 is typically 1750 Ȧ (175 nm), and is significantly thinner than the thickness of other layers including the second substrate 1 .

[0242] The first gap layer 8 is formed by applying a material such as a UV-curable resin onto the reflective surface 2 formed on the second substrate 1 by sp...

no. 2 approach

[0252] 7 is a schematic cross-sectional view of the structure of a hologram recording medium according to a second embodiment of the present invention. In the hologram recording medium 22 according to the second embodiment of the present invention, the servo pit pattern 3 is formed on the polycarbonate resin or glass substrate 1, and the servo pit pattern surface is coated by using aluminum, gold, platinum, or the like A reflective surface 2 is formed. The height of the servo pit pattern 3 is the same as in the case of the first embodiment in which the height of the servo pit pattern is typically 1750 Ȧ (175 nm).

[0253] The difference in structure between the second embodiment and the first embodiment is that the hologram recording medium 22 according to the second embodiment has the second gap layer 7 formed between the wavelength selective reflection layer 6 and the hologram recording layer 4 .

[0254] After the first gap layer 8 is formed, the wavelength selective refle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com