Method and apparatus for crystallization of organic compound through adiabatic cooling

一种有机化合物、隔热冷却的技术,应用在热交换冷却结晶、结晶装置的总布置图、有机化学等方向,能够解决装置成本系统相抵、提高设备成本和维修成本等问题,达到降低设备费、降低运行费、减少能量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

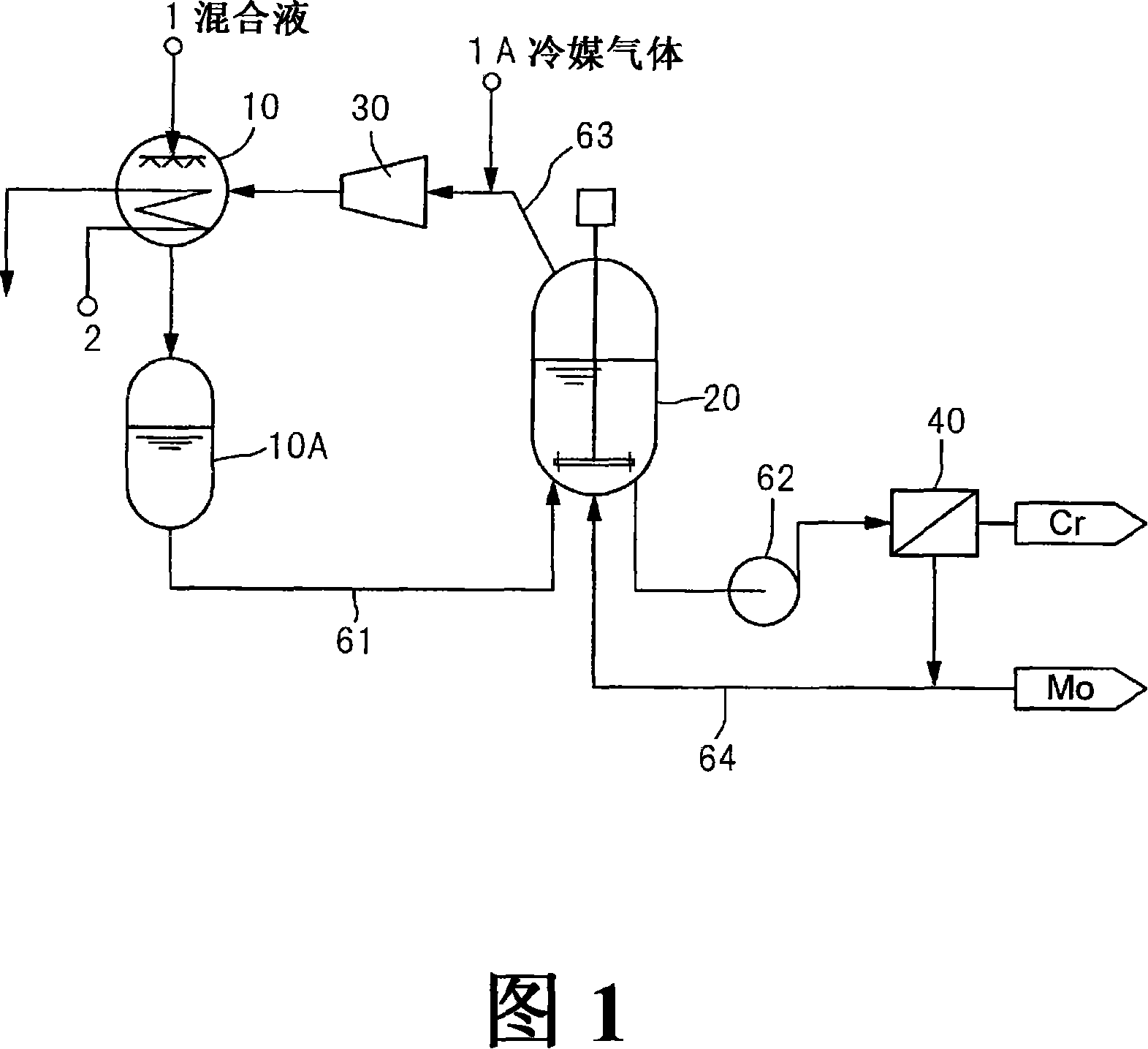

[0053] FIG. 1 shows a basic embodiment, which has an absorption condenser 10, a crystallization tank 20, a compressor 30, and a solid-liquid separation device 40.

[0054] The mixed solution 1 of the target organic compound containing the refrigerant (the target solution of the crystallization operation, for example, the mixed liquid of the eutectic multi-component system containing p-xylene and its isomers) is introduced into the absorption condenser 10, where Where refrigerant vapor (such as propane) is absorbed and condensed to form a homogeneous refrigerant mixture, it is introduced into the crystallization tank 20 through the pipe 61 from the storage tank 10A that temporarily stores the absorption condensate, where the condensate containing the refrigerant is Operation of adiabatic cooling and evaporation of refrigerant.

[0055] The crystal slurry produced by this operation is taken out of the crystallization tank 20 by the pump 62, and is separated into a crystal stream Cr ...

no. 2 approach

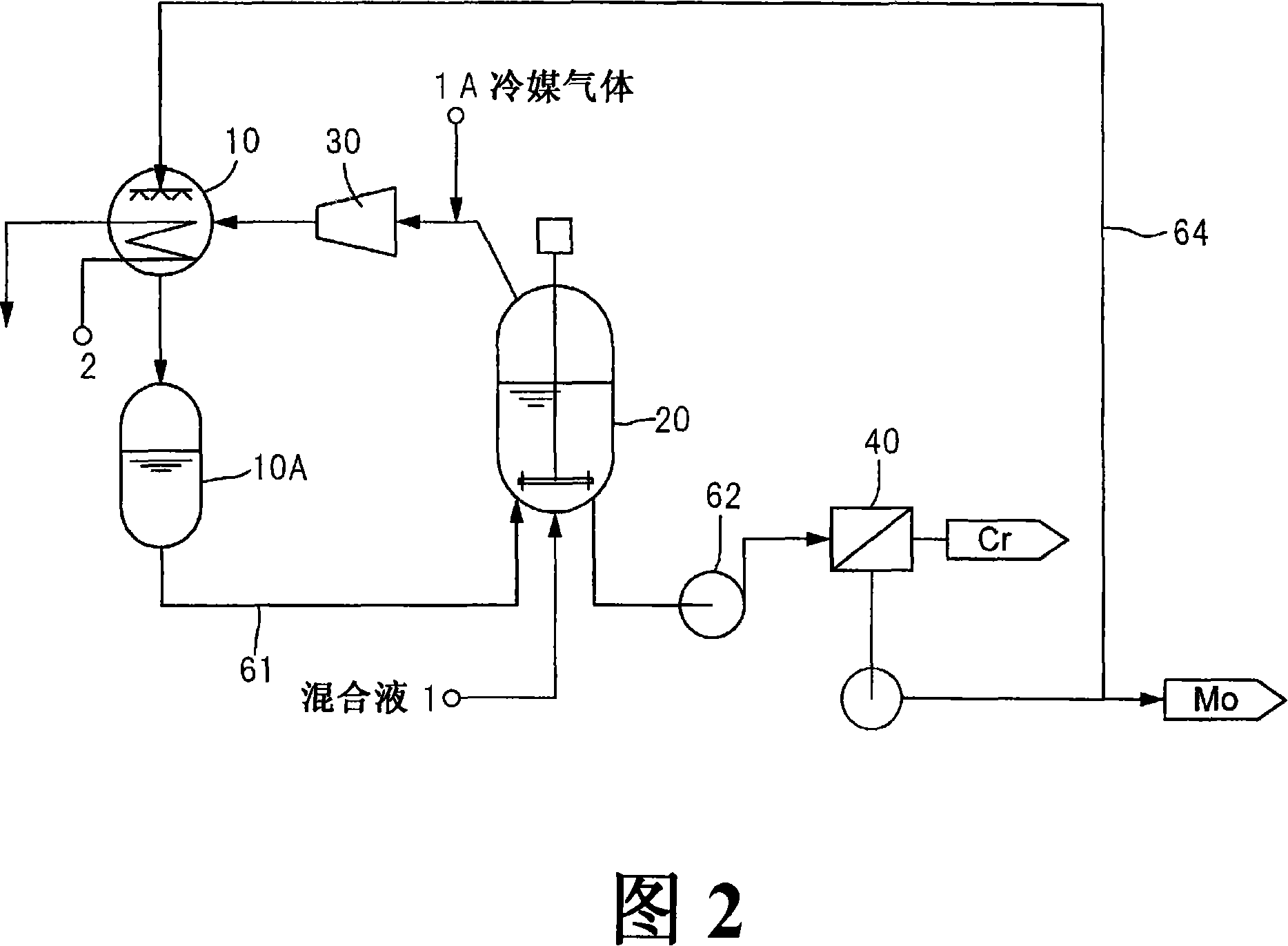

[0062] 2 shows a second embodiment. The crystal slurry taken out from the crystallization tank 20 is separated by the solid-liquid separator 40, and the mother liquor stream Mo after separation is returned to the absorption condenser 10 via the pipe 64. In the solid-liquid separator 40 in the state of being dissolved in the filtrate, part of the refrigerant discharged to the outside of the system is recovered by a subsequent distillation tower, or can be supplied to the suction part of the compressor 30 as a supplement (see also FIG. 1).

[0063] Centrifugal separators, filters or cyclones can be used for solid-liquid separation.

[0064] The original organic compound mixed solution 1 may be directly supplied to the crystallization tank 20.

[0065] Crystallization method description

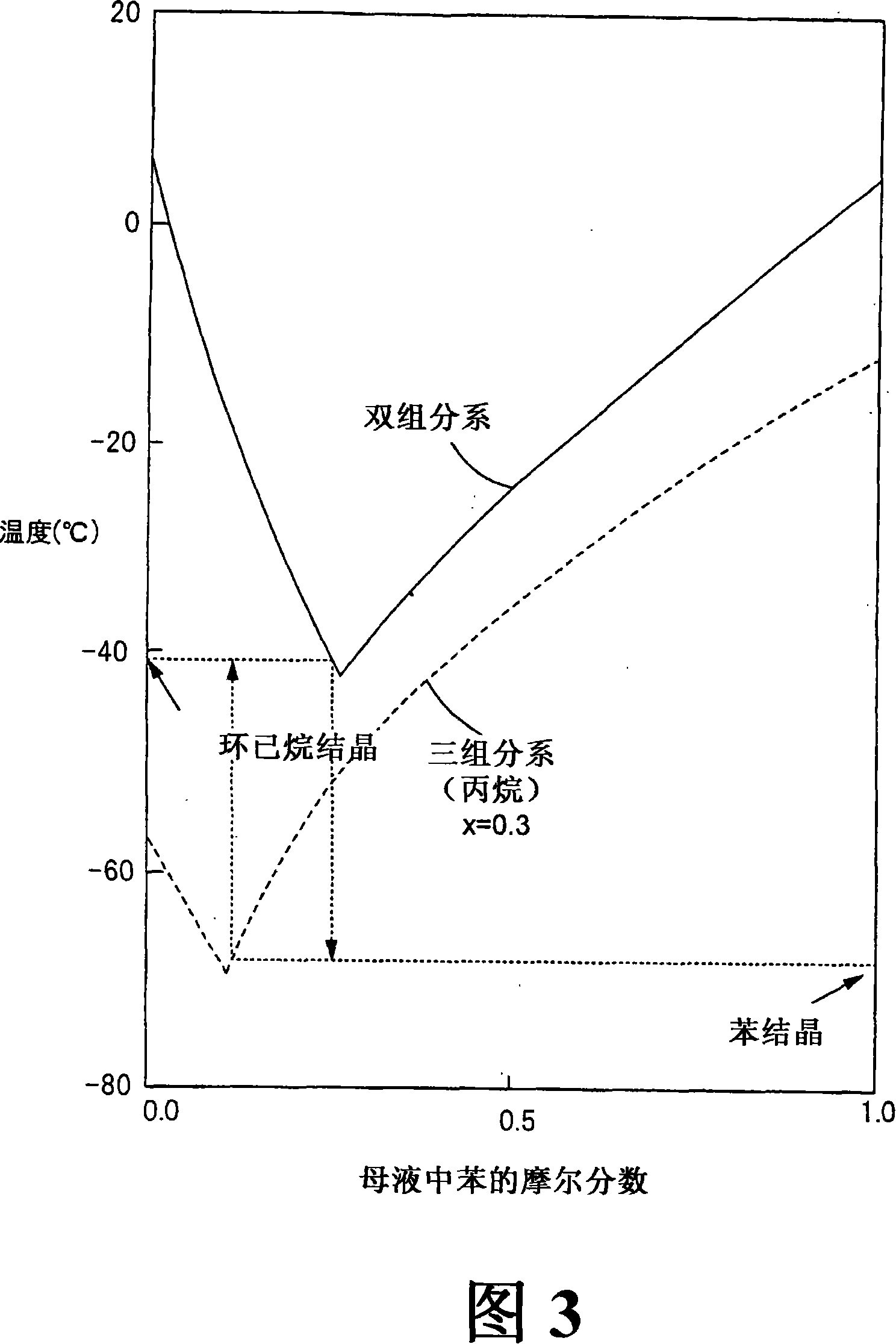

[0066] The crystallization method will be explained using the example of the benzene-cyclohexane system.

[0067] In the general manufacturing method of the chemical industry, cyclohexane is manufac...

Embodiment 1

[0085] In the following examples, crystallization was performed in the method shown in FIG. 1. As the crystallization tank 20, a vertical crystallization machine (diameter 300mm×height 1.5m, slurry volume 25L) was used as the absorption agglomerator 10, A horizontal tube type condenser was used, and a centrifugal separator was used as the solid-liquid separator 40. And 30 is a vapor compressor, and 10A is a storage tank for temporarily storing and absorbing condensate.

[0086] The normal temperature mixed xylene raw material with a p-xylene content of 80 to 90% is supplied to the absorption condenser 10 at a flow rate of 15 to 25 kg / hr, and simultaneously pressurized from the crystallization tank 20 to 0.2 to 0.7 MPa by the compressor 30 The steam contacts and mixes and condenses at about 30°C. The obtained agglomerate is a xylene solution mixed with propane with a propane concentration of 10 to 30%, which is introduced into a crystallization tank 20 operating at -10 to 0°C under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com