Structure of silicon micromachine resonant micro-pressure sensor chip and its manufacturing method

A micro-pressure sensor and silicon micro-mechanical technology are applied in fluid pressure measurement of elastic deformation gauge, fluid pressure measurement of acoustic method, measurement of force by measuring the frequency change of stressed vibrating elements, etc., and can solve many problems. Difficult to ensure the uniformity of ultra-thin films and other issues, to achieve the effect of eliminating complex structures, high signal-to-noise ratio, and good long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

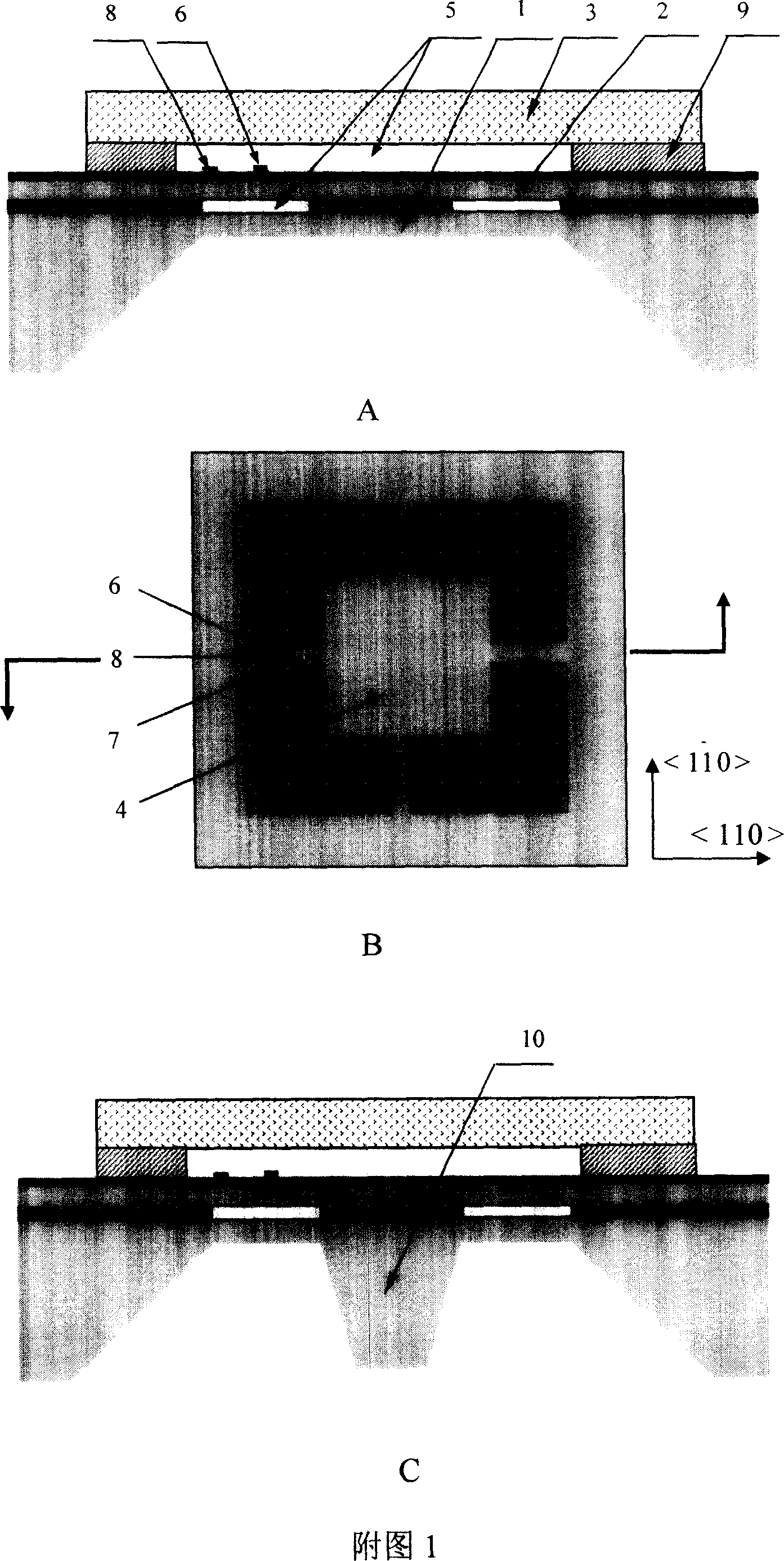

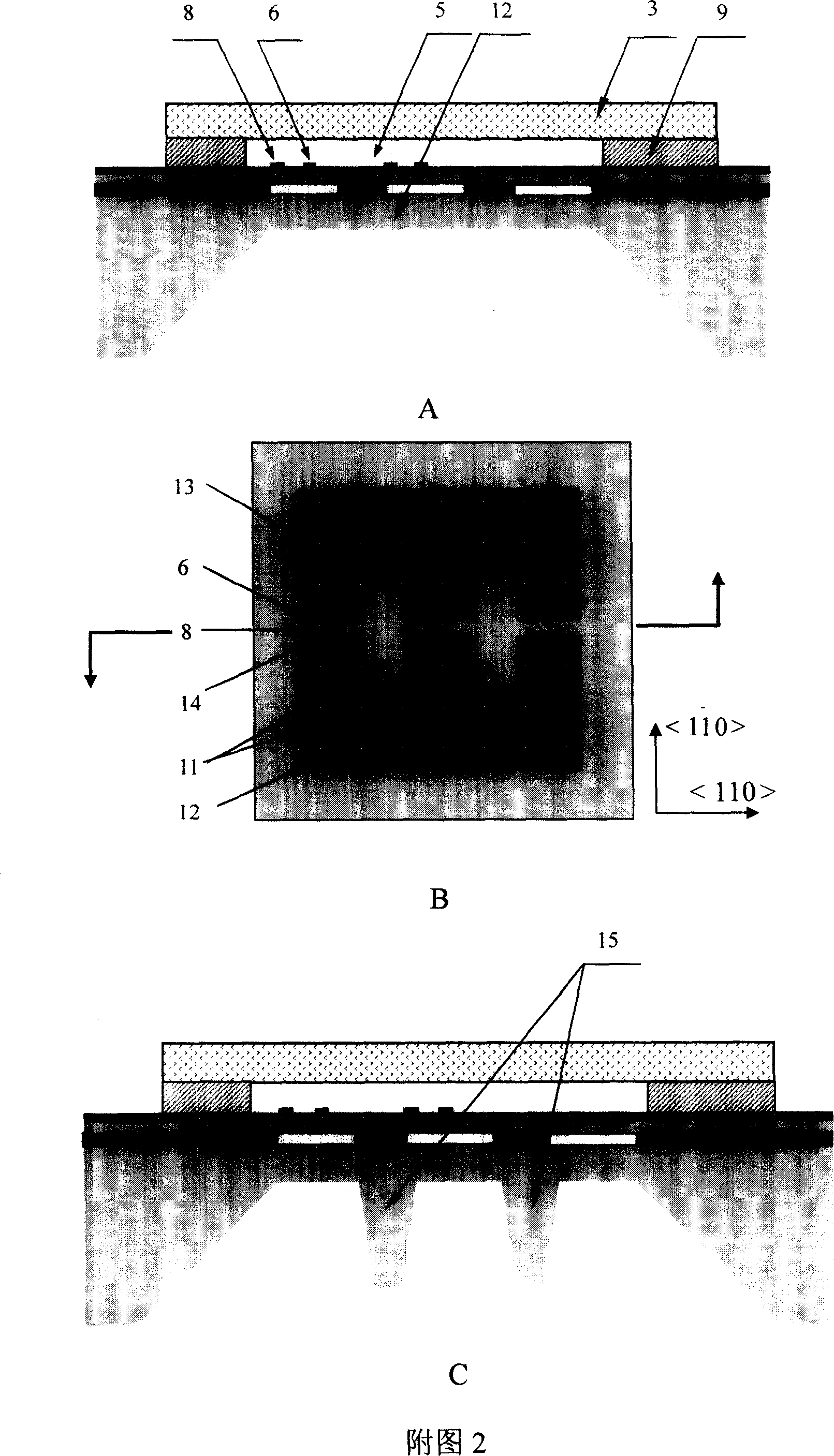

[0037] A silicon micromechanical resonant micro-pressure sensor chip (without overvoltage protection) with a measuring range of 10KPa for electrothermal excitation / piezoresistive detection is manufactured by using the technical solution 1 of the present invention. Its production process is as follows:

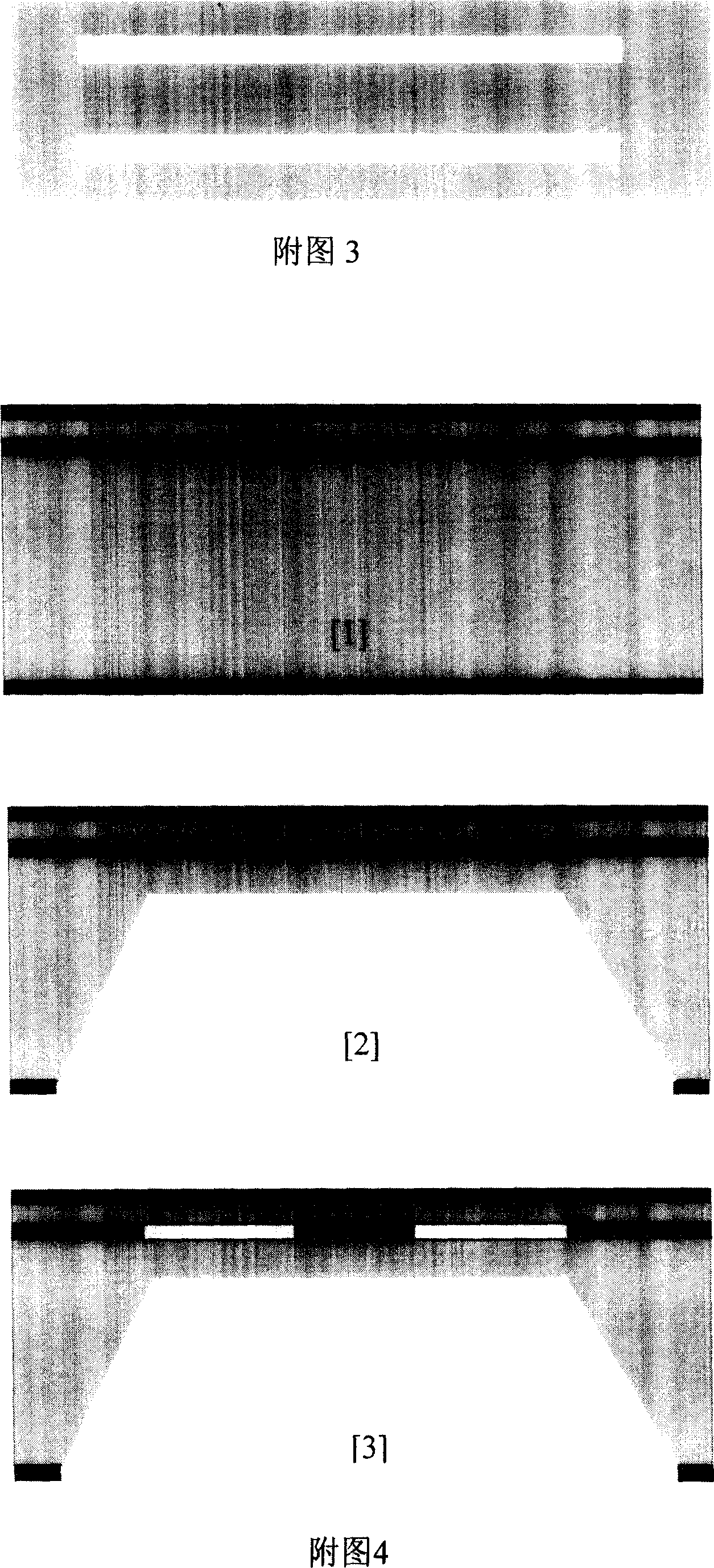

[0038] 1) The original silicon wafer is an N-type, (100) plane SOI silicon wafer, the thickness of the top silicon layer is 10 μm, the thickness of the buried silicon dioxide layer is 1.5 μm, and the thickness of the substrate silicon wafer is 380 μm. Thermal oxidation, oxide layer thickness 1μm. (See Attachment 4[1])

[0039] 2) The backside photolithography back etches the window. Silicon is etched on the back side with an etching depth of 360 μm. (see attached drawing 4[2])

[0040] 3) The front photolithographic pressure-sensitive diaphragm 1 and the double-ended fixed support beam 2 . The length of one side of the diaphragm is 2000 μm, and the length of four sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com