Modified Ca-Co-O system doped transition metal composite oxides and preparation method thereof

A composite oxide, transition metal technology, applied in the direction of calcium/strontium/barium oxide/hydroxide, cobalt oxide/cobalt hydroxide, etc., can solve the problems of easy generation of impurities, high reaction temperature, long reaction time, etc. To achieve the effect of uniform particles, low reaction temperature and short synthesis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

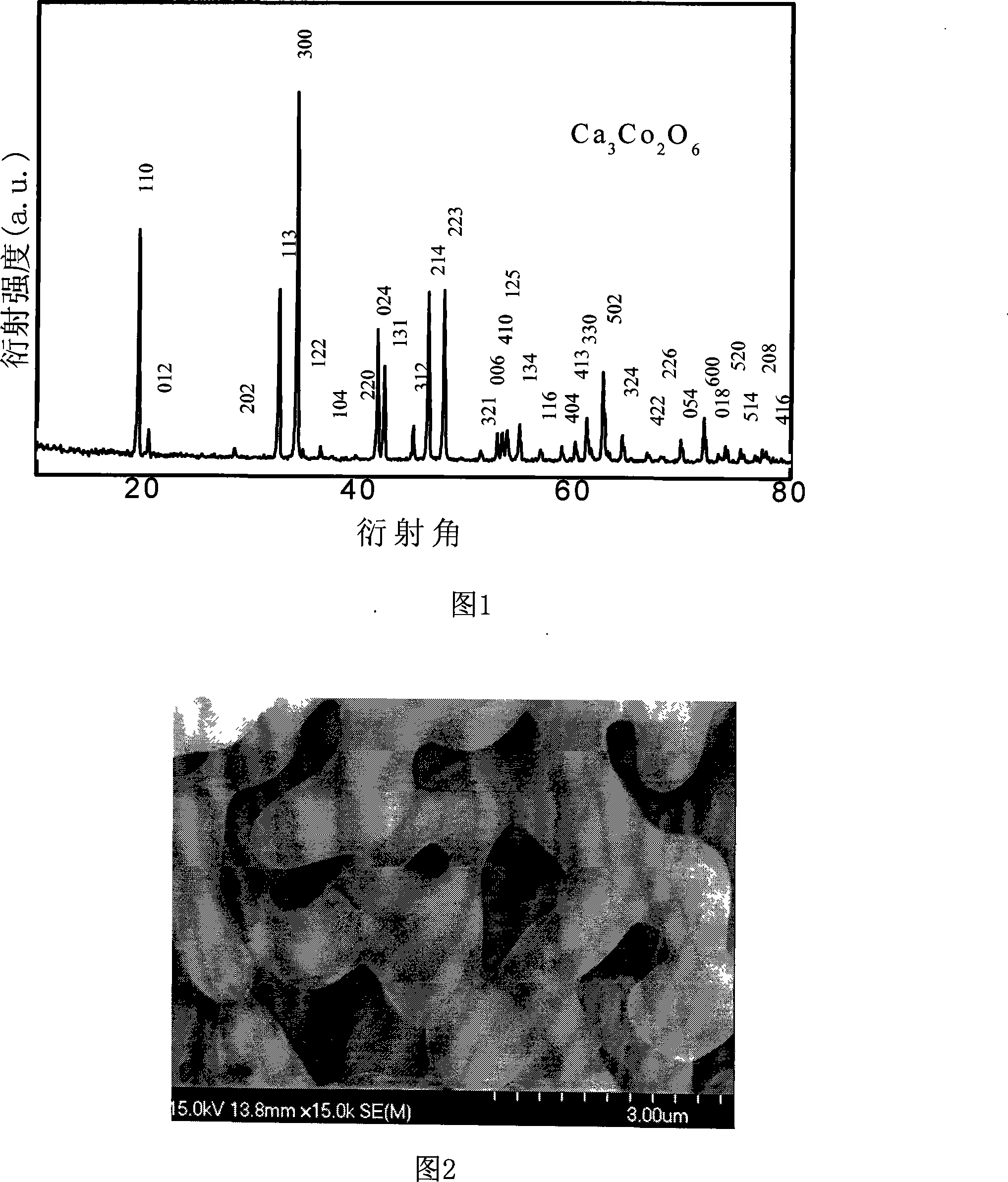

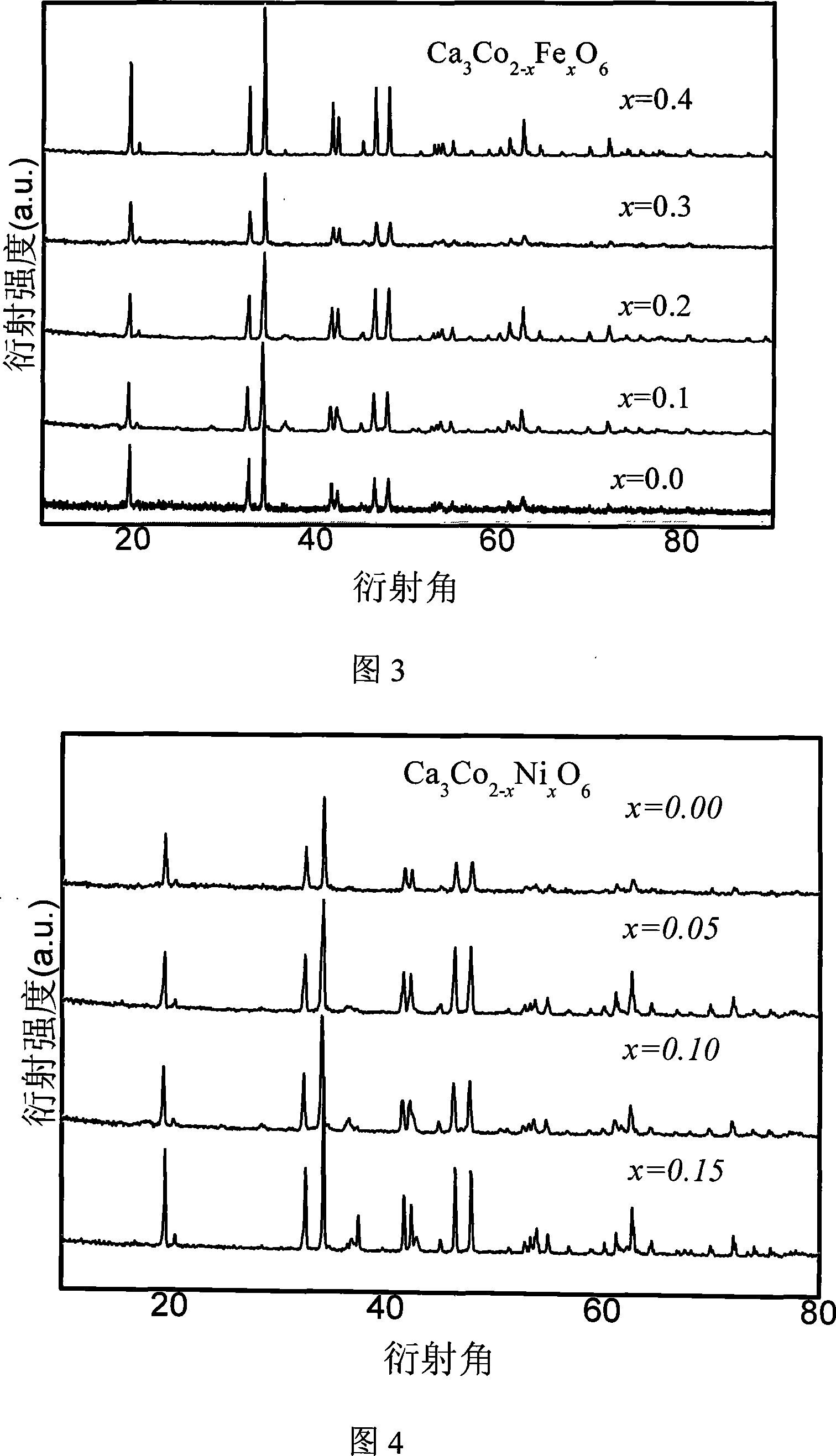

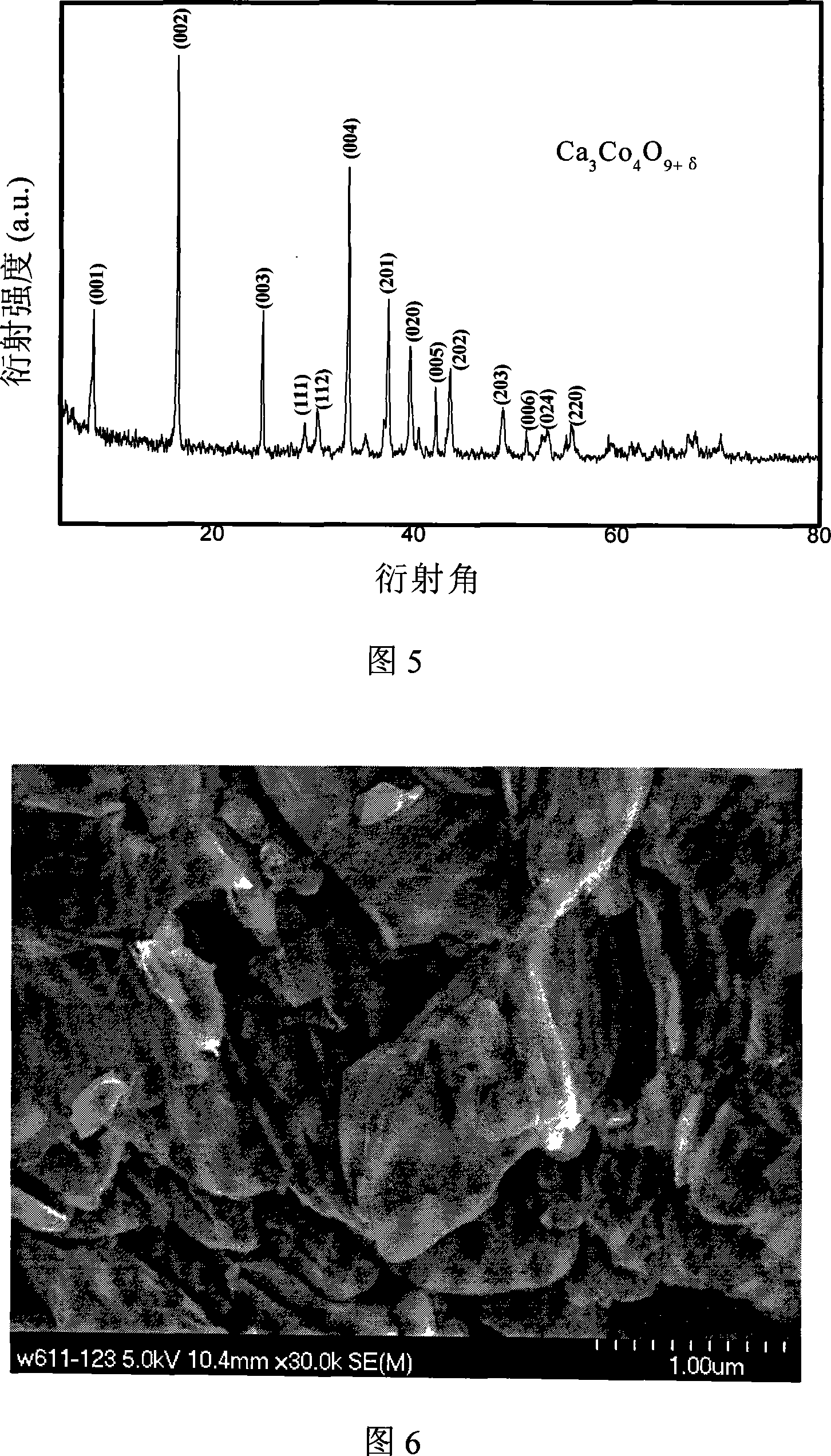

[0011] Specific implementation mode 1: In this implementation mode, the general formula of the doped modified Ca-Co-O system transition metal composite oxide is Ca 3 co 2-x m x o 6 or Ca 3-x-y m x N y co 4 o 9+δ Wherein M is Fe, Ni, Nd or Er, and N is Na or Bi, and its preparation method is to realize by following reaction: one, Ca(NO 3 ) 2 4H 2 Nitrate of O, M and Co(NO 3 ) 2 ·6H 2 O, or Ca(NO 3 ) 2 4H 2 O, M nitrate, N nitrate and Co(NO 3 ) 2 ·6H 2 O was dissolved in deionized water respectively, and then mixed evenly according to the stoichiometric ratio of the molecular formula, and then slowly poured into the citric acid solution according to the molar ratio of citric acid to all metal ions at 1.5-2:1, and then ultrasonically oscillated for 20-40 minutes to form Sol; 2. The sol obtained in step 1 is processed by microwave heating. The microwave heating temperature is 100° C. and the heating time is 20-60 minutes to obtain a wet gel; 3. Dry the wet gel ob...

specific Embodiment approach 2

[0012] Specific embodiment two: the difference between this embodiment and specific embodiment one is that Ca(NO 3 ) 2 4H 2 Nitrate of O, M and Co(NO 3 ) 2 ·6H 2 O is mixed according to the stoichiometric ratio of the molecular formula. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Specific embodiment three: the difference between this embodiment and specific embodiment one is that Ca(NO 3 ) 2 4H 2 O, M nitrate, N nitrate and Co(NO 3 ) 2 ·6H 2 O is mixed according to the stoichiometric ratio of the molecular formula. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com