Construction method for composite pattern having both micron and nano structures

A micro-nano and construction method technology, applied in the field of micro-nano material preparation, can solve problems that have not been seen before, achieve the effects of saving equipment and instruments, widening the range of raw material selection, and simple and easy methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

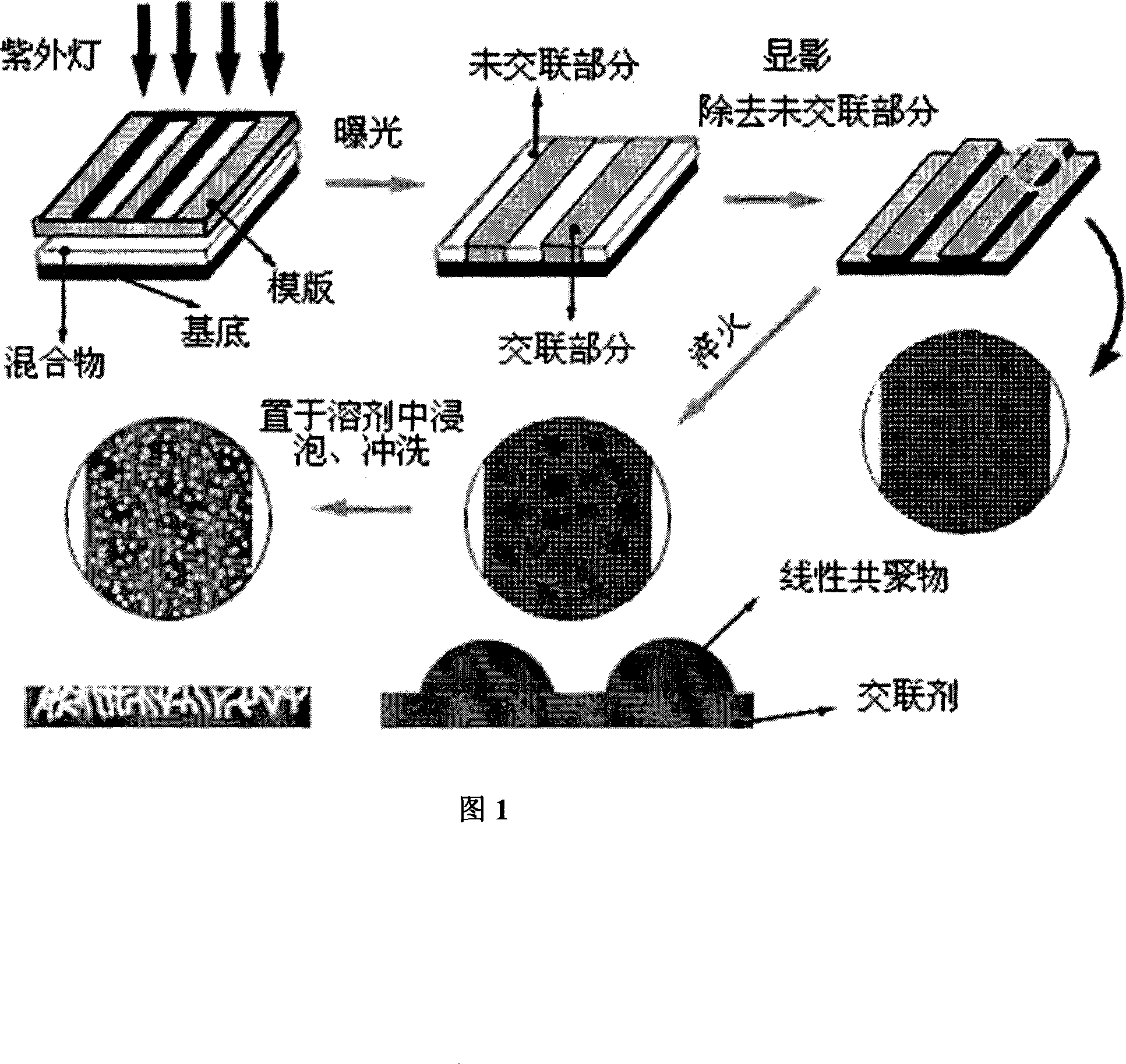

Method used

Image

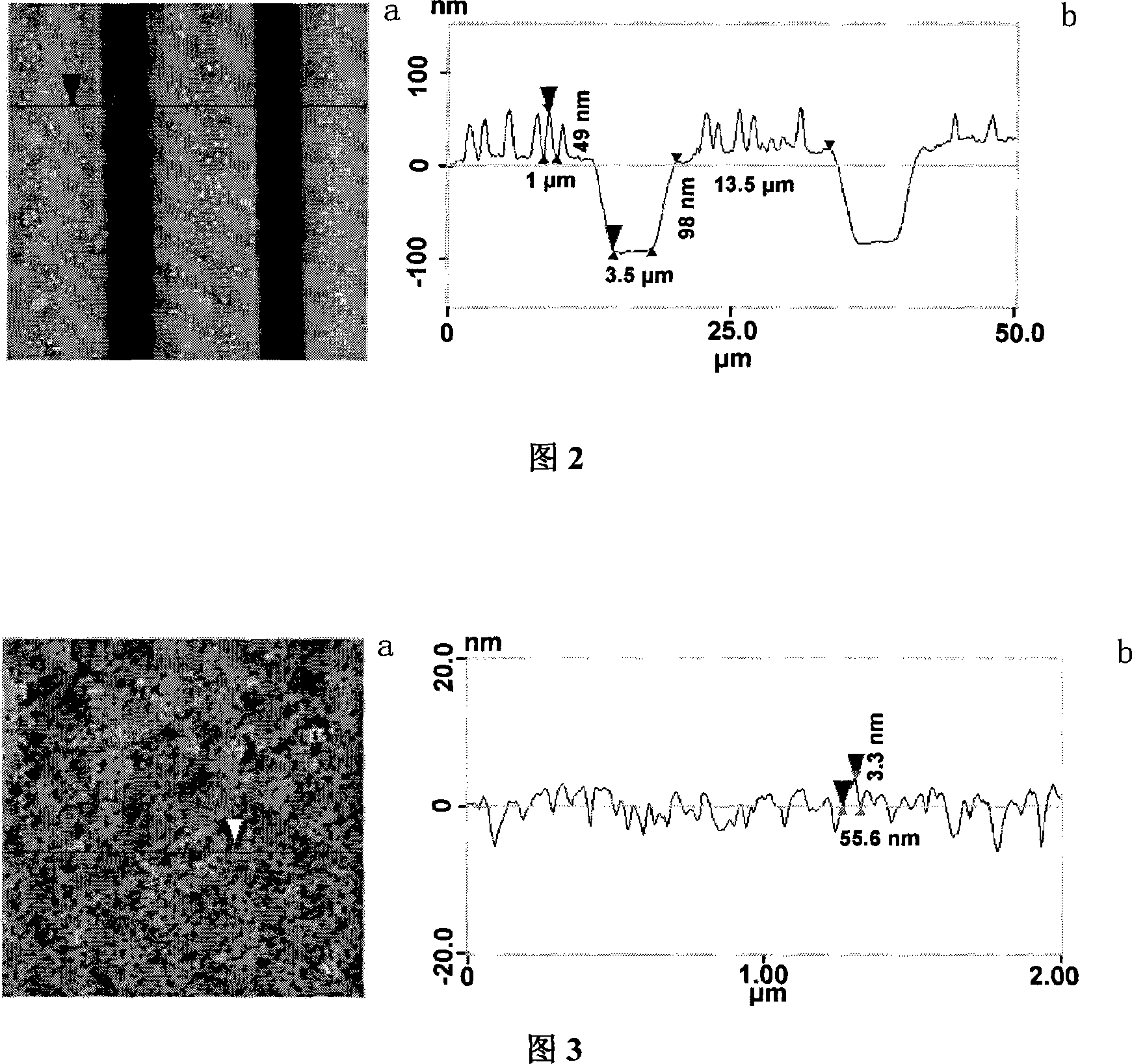

Examples

Embodiment 1

[0023] 1. Treatment of the substrate

[0024] Boil the glass sheet substrate in a mixed solution containing concentrated sulfuric acid and hydrogen peroxide for half an hour. The mass ratio of concentrated sulfuric acid and hydrogen peroxide is 7:3, then place it in acetone for 30 minutes, rinse it with deionized water, and dry it. .

[0025] 2. Prepare the solution of linear copolymer, crosslinker and photoinitiator

[0026] Select the linear random copolymer PS-r-PMMA, the crosslinking agent is TMPTA (trimethylolpropanetriacrylate), the photoinitiator is 2,2'-dimethoxy-2-phenylacetophenone, and the above three substances are dissolved in In chloroform, the solid content of the solution is 1%, wherein PS-r-PMMA:TMPTA (mass ratio)=5:3, and the photoinitiator accounts for 5% of the mass sum of the random copolymer and TMPTA.

[0027] 3. Spin coating film formation

[0028] The solution was spin-coated on a spin coater to form a film. The selected rotational speed was 1.2krad...

Embodiment 2

[0034] 1. Treatment of the substrate

[0035] Boil the glass substrate in a mixed solution containing concentrated sulfuric acid and hydrogen peroxide for 1 hour. The mass ratio of concentrated sulfuric acid to hydrogen peroxide is 10:1, then place it in acetone for 15 minutes, rinse it with deionized water, and dry it. .

[0036] 2. Prepare the solution of linear copolymer, crosslinker and photoinitiator

[0037] Select the linear random copolymer PS-r-PEMA, the crosslinking agent is TMPTA (trimethylolpropanetriacrylate), the photoinitiator is isopropyl thioxanthone, and the above three substances are dissolved in toluene, and the solid content of the solution is 5%. , wherein PS-r-PEMA: TMPTA (mass ratio) = 1: 1, the photoinitiator accounts for 10% of the sum of the mass of the random copolymer and TMPTA.

[0038] 3. Spin coating film formation

[0039] The solution was spin-coated on a spin coater to form a film. The selected rotational speed was 1.5krad / min for the firs...

Embodiment 3

[0045] 1. Treatment of the substrate

[0046] Boil the glass substrate in a mixed solution containing concentrated sulfuric acid and hydrogen peroxide for half an hour. The mass ratio of concentrated sulfuric acid and hydrogen peroxide is 1:1, then place it in acetone for 15 minutes, and finally rinse it with deionized water and dry it. .

[0047] 2. Prepare the solution of linear copolymer, crosslinker and photoinitiator

[0048] Choose linear random copolymer PS-r-PBMA, cross-linking agent is 2,2-bis(4-acrylate pentaethoxy) phenyl-propane, photoinitiator is benzophenone, above-mentioned three kinds The substance is dissolved in 1,1,2-trichloroethane, the solid content of the solution is 1%, wherein PS-r-PBMA:crosslinking agent (mass ratio)=3:5, photoinitiator accounts for random copolymer and 5% of the sum of the mass of the crosslinking agent.

[0049] 3. Spin coating film formation

[0050] The solution was spin-coated on a spin coater to form a film. The selected rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com