Preparation method of battery positive plate, positive plate and lithium ionic cell

A lithium ion battery and a manufacturing method technology, which are applied to the production of a positive electrode sheet of a battery and the field of a positive electrode sheet produced and a lithium ion battery, can solve the problems that cannot be completely removed, affect the performance of the battery, the battery is bulging, etc., and achieve a good cycle. Features, small deformation, no pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

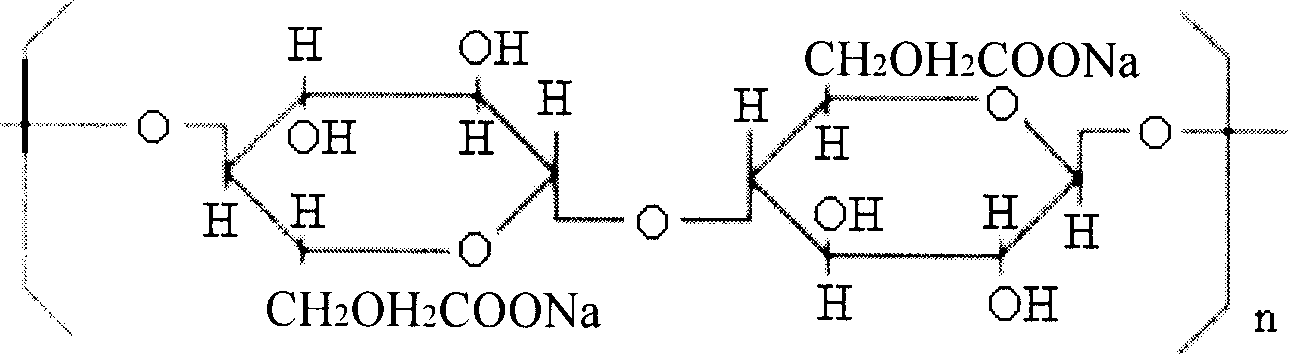

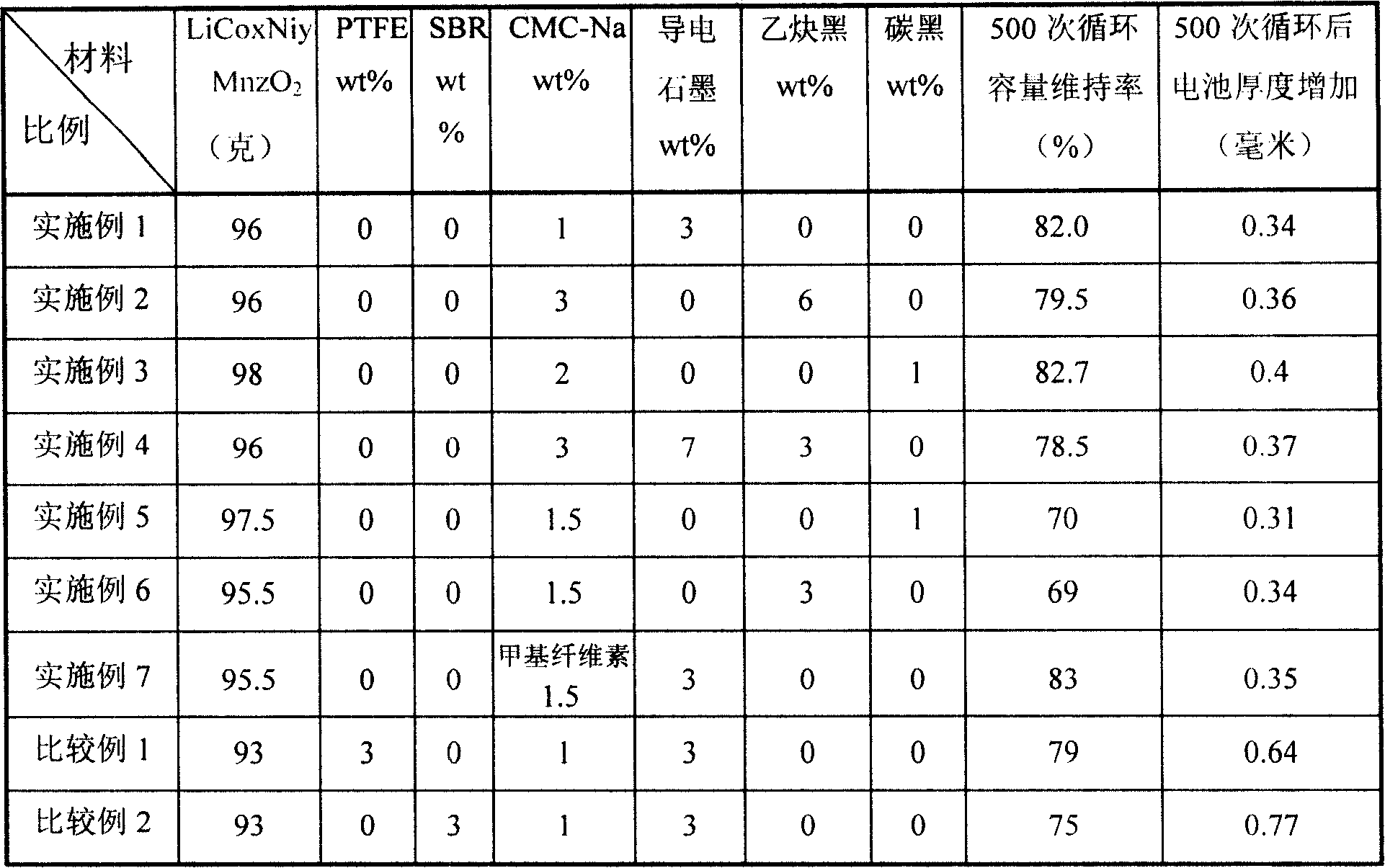

[0021] Weigh the average particle diameter D 50 9 micron cathode active material LiCoxNiyMnzO 2 96 grams, 0.96 grams of binder carboxymethylcellulose sodium (CMC-Na), 2.88 grams of conductive agent graphite, the graphite average particle diameter D 50 0.2 micron, resistivity 5×10 -5 Ohm·cm, specific surface area is 350 m2 / g. The above-mentioned sodium carboxymethylcellulose (CMC-Na) was added into 48 grams of deionized water, stirred and dissolved with a vacuum mixer for 0.5 hour, and the stirring speed was 500 rpm, so that the CMC-Na was completely dissolved in the deionized water.

[0022] After mixing the above-mentioned conductive agent and positive electrode active material into a dry mixture, add it to the prepared CMC-Na binder, and stir for 2 hours with a vacuum mixer at a stirring speed of 800 rpm to obtain a uniformly mixed slurry.

[0023] The obtained electrode material slurry is drawn and coated on the aluminum foil of the electrode collector with a thickness ...

Embodiment 2

[0025] Positive active material LiCoxNiyMnzO 2 96 grams, 2.88 grams of carboxymethylcellulose sodium (CMC-Na), 5.76 grams of conductive agent acetylene black, 57.6 grams of deionized water, adopt the method of embodiment 1 to make the battery positive electrode sheet.

Embodiment 3

[0027] Positive active material LiCoxNiyMnzO 2 98 grams, 1.96 grams of carboxymethylcellulose sodium (CMC-Na), 0.98 grams of conductive agent carbon black, 49 grams of deionized water, adopt the method of embodiment 1 to make the battery positive electrode sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com