Method for preparing cellulose gel film

A cellulose gel and cellulose technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve the effect of convenient molding, avoiding rapid random accumulation, compact and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

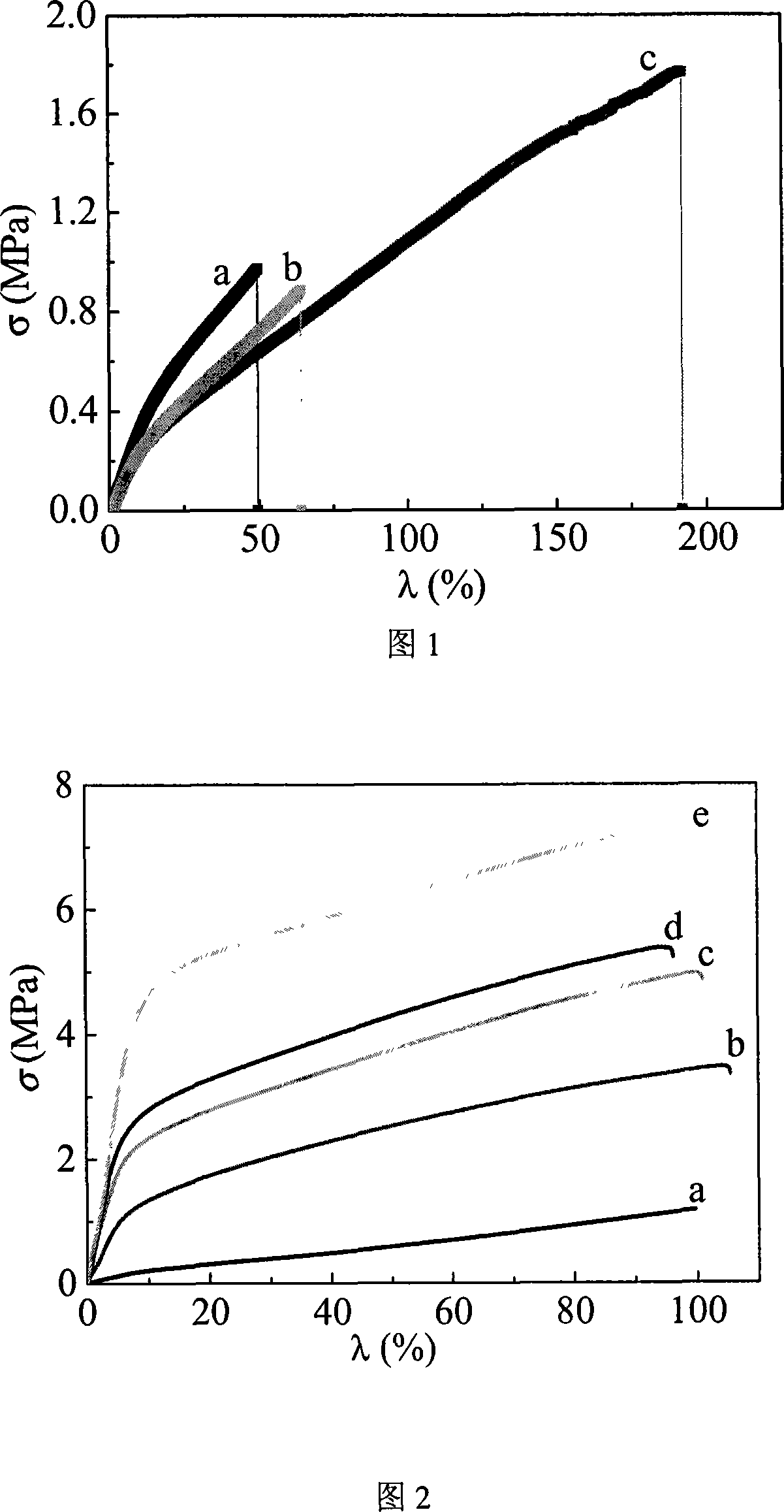

[0023] Disperse 5 g of cotton linter cellulose pulp in 100 g of 4.5 wt% NaOH / 9.5 wt% thiourea mixed aqueous solution precooled to -5°C, and stir for 10 minutes to obtain a transparent cellulose solution. The cellulose solution was centrifuged and defoamed at 8000rpm / min for 10 minutes with an ultracentrifuge, and then poured into a special glass box and sealed. The glass frame containing the cellulose solution was frozen at -20°C for 12 hours for solution gel treatment, and then thawed at 5°C to obtain a cellulose physical gel, and then the obtained cellulose physical gel was taken out of the mold and placed The sodium hydroxide and thiourea in the gel were removed in deionized water, the deionized water was renewed every 5 hours, and the cellulose hydrogel film was obtained after repeated washing for about three times. Its stress-strain curve is shown in Figure 2a.

Embodiment 2

[0025] Disperse 7g of cotton linter cellulose pulp in 100g of 7.0wt% NaOH / 10.5wt% urea mixed aqueous solution precooled to -10°C, and stir for 10 minutes to obtain a transparent cellulose solution. The solution was centrifuged and defoamed at 8000rpm / min for 10 minutes with an ultracentrifuge, and then poured into a special glass box and sealed. The glass frame containing the cellulose solution was stored at 5°C for three weeks for solution gel treatment to obtain a cellulose physical gel, and then the resulting cellulose physical gel was taken out from the mold and placed in deionized water to remove the cellulose in the gel. Sodium hydroxide, urea, and deionized water are renewed every 5 hours, and the cellulose hydrogel membrane is obtained after repeated washing three times.

Embodiment 3

[0027] Disperse 4g of cotton linter cellulose pulp in 100g of 6.0wt% NaOH / 9.5wt% urea mixed aqueous solution precooled to -5°C, and stir for 10 minutes to obtain a transparent cellulose solution. The cellulose solution was centrifuged and defoamed at 8000rpm / min for 10 minutes with an ultracentrifuge, and then poured into a special glass box and sealed. Store the glass frame containing the cellulose solution at 25°C for one week for solution gel treatment to obtain a cellulose physical gel, then remove the obtained cellulose physical gel from the mold and place it in deionized water to remove the gel Sodium hydroxide and urea, and deionized water are renewed every about 5 hours, and the cellulose hydrogel membrane is obtained after repeated washing three times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com