Gallo catechin and gallate microcapsule granule and preparation technique thereof

A technology of epigallocatechin and gallate, applied in the field of hydrophobic microcapsules, can solve the problem of high drug loading, and achieve the effects of good stability, good fluidity and good encapsulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

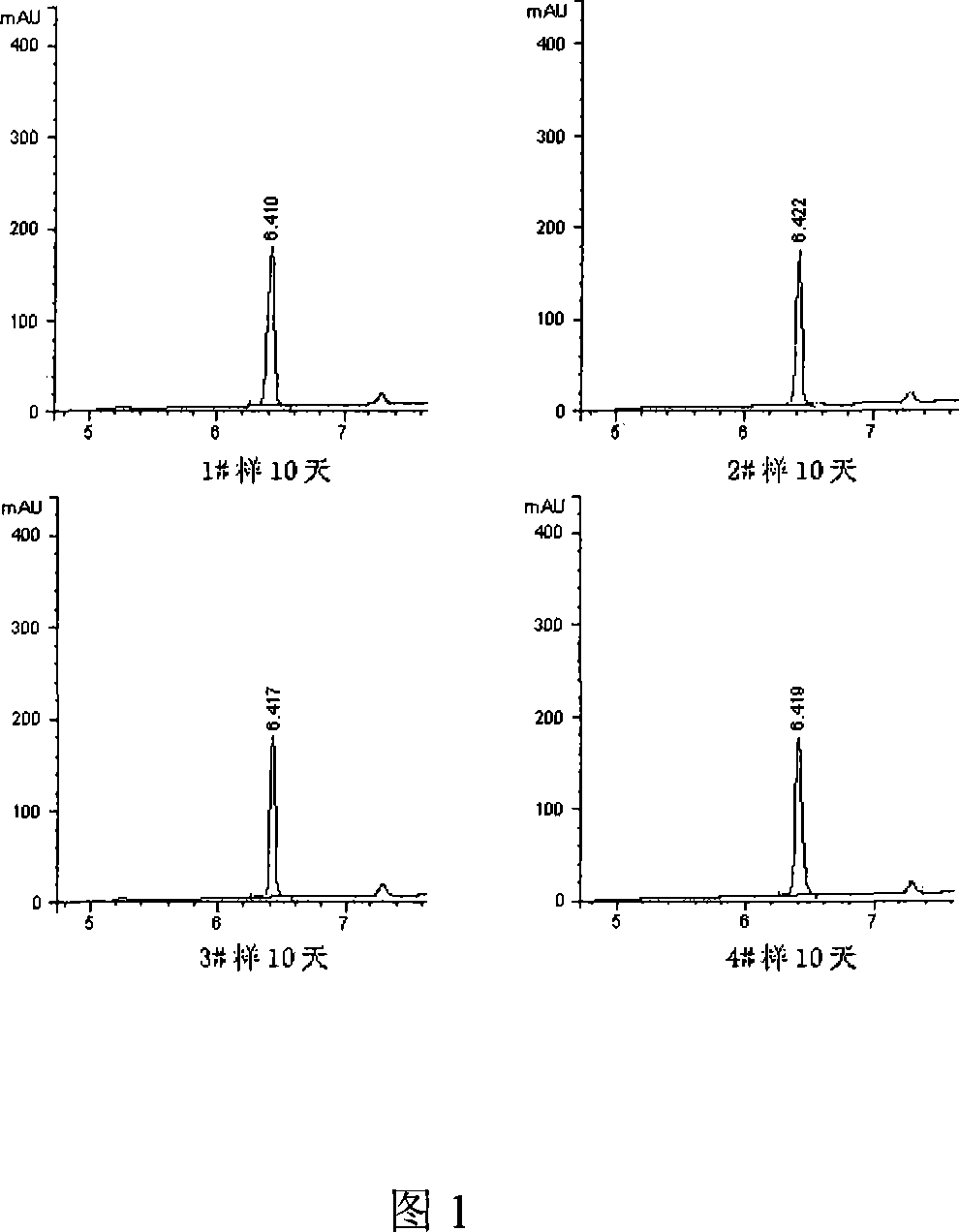

Image

Examples

Embodiment 1

[0026] Embodiment 1. A kind of epigallocatechin gallate microcapsule particle, it is made up of the composition of following weight ratio:

[0027] Epigallocatechin gallate 2,

[0028] Ethyl cellulose 1

[0029] Polyethylene glycol 0.1,

[0030] Sodium carboxymethyl starch 1.8.

[0031] Its preparation process is:

[0032] (1) The ethyl cellulose of 1 weight part is dissolved in the dichloromethane, prepares the concentration that obtains the ethyl cellulose solution at 5% (g / v),

[0033] (2) Add 2 parts by weight of epigallocatechin gallate, 0.1 parts by weight of polyethylene glycol and sodium carboxymethyl starch of 1.8 parts by weight in the above-mentioned ethyl cellulose solution, stir to make it fully suspended, The stirring speed is controlled at 1500 rpm, and petroleum ether is slowly added dropwise until the system is completely precipitated, and the precipitated microcapsules are separated from the solvent to obtain a mixture of cysts and solvent A, and the cyst...

Embodiment 2

[0034] Embodiment 2. A kind of epigallocatechin gallate microcapsule particle, it is made up of the composition of following weight ratio:

[0035] Epigallocatechin gallate 3,

[0036] Ethyl cellulose 1

[0037] Polyethylene glycol 0.2

[0038] Sodium carboxymethyl starch 0.5.

[0039] Its preparation process is:

[0040] (1) The ethyl cellulose of 1 weight part is dissolved in the dichloromethane, prepares the concentration that obtains the ethyl cellulose solution at 6% (g / v),

[0041] (2) Add 3 parts by weight of epigallocatechin gallate, 0.2 parts by weight of polyethylene glycol and sodium carboxymethyl starch of 0.5 parts by weight in the above-mentioned ethyl cellulose solution, stir to make it fully suspended, The stirring speed is controlled at 1500 rpm, and petroleum ether is slowly added dropwise until the system is completely precipitated, and the precipitated microcapsules are separated from the solvent to obtain a mixture of cysts and solvent A, and the cysts...

Embodiment 3

[0042] Embodiment 3. A kind of epigallocatechin gallate microcapsule particle, it is made up of the composition of following weight ratio:

[0043] Epigallocatechin gallate 2,

[0044] Ethyl cellulose 1.5

[0045] Polyethylene glycol 0.05,

[0046] Sodium Carboxymethyl Starch 1.

[0047] Its preparation process is:

[0048] (1) Dissolve 1.5 parts by weight of ethyl cellulose in the fraction <45°C under normal pressure of the solvent mixture A separated by the above-mentioned method one, and prepare the ethyl cellulose solution with a concentration of 7% (g / v),

[0049] (2) Add 2 parts by weight of epigallocatechin gallate, 0.05 parts by weight of polyethylene glycol and sodium carboxymethyl starch of 1 part by weight in the above-mentioned ethyl cellulose solution, stir to make it fully suspended, Control the stirring speed at 1500 rev / min, slowly add dropwise the distillate of the solvent mixture A separated from the above-mentioned method under normal pressure > 60°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com