Method for synthesizing monomolecular phosphorus-nitrogen expansion type fire retardant

A synthesis method and single-molecule technology, applied in the direction of phosphorus organic compounds, etc., can solve the problems of poor compatibility between flame retardants and materials, complex single-molecule IFR process, environmental pollution, etc., to achieve good compatibility and protect physical and mechanical properties. , the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

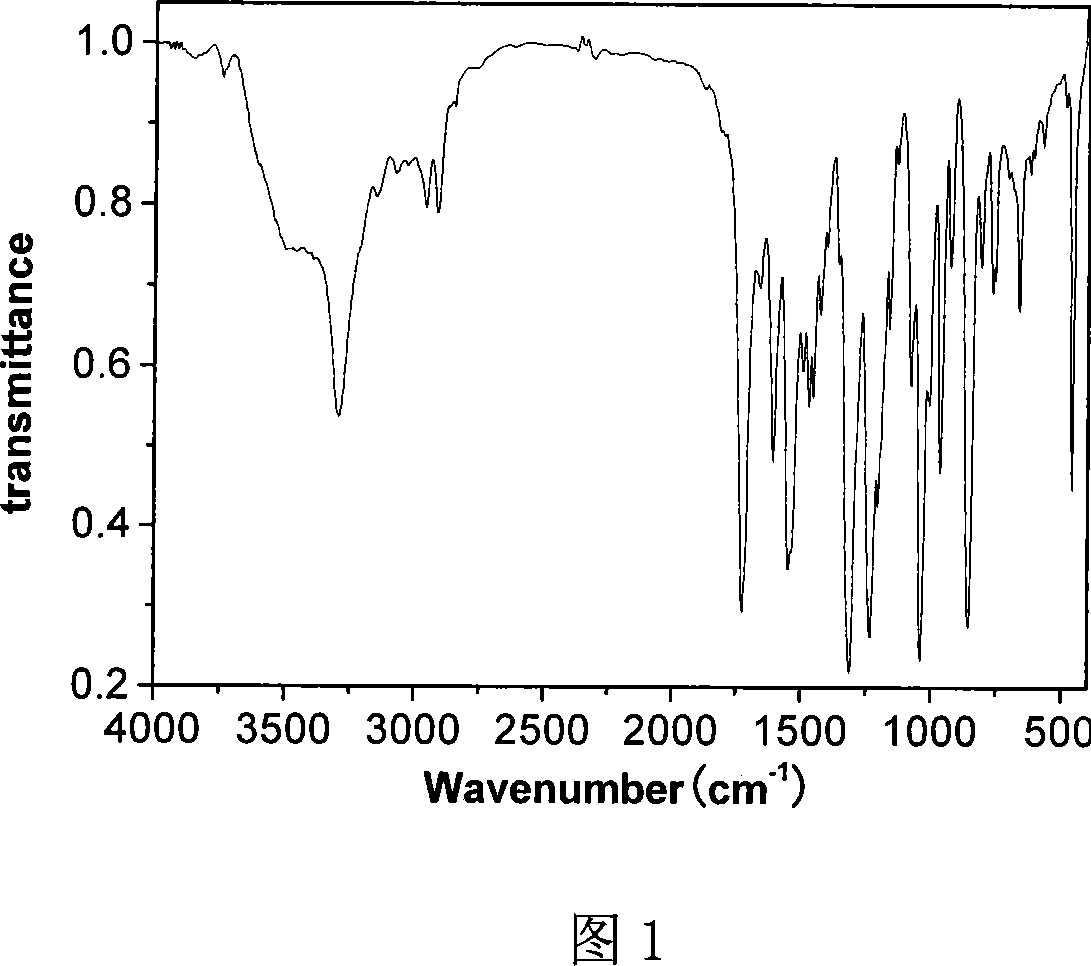

Image

Examples

Embodiment 1

[0030] Add 1.36g of pentaerythritol and 50ml of dioxane to a 250ml round bottom flask equipped with a nitrogen inlet and outlet, a drying device, a pear-shaped separating funnel, and a stirring device, stir well to dissolve the pentaerythritol, and use a pear-shaped separating funnel to dissolve the pentaerythritol. 1.53g of phosphorus oxychloride was added dropwise and reacted for 1h under stirring, a large amount of white precipitates were produced. Filter, wash twice with deionized water, then wash twice with acetone, and dry in vacuum for 24 hours to obtain a white powdery solid with a yield of 95%.

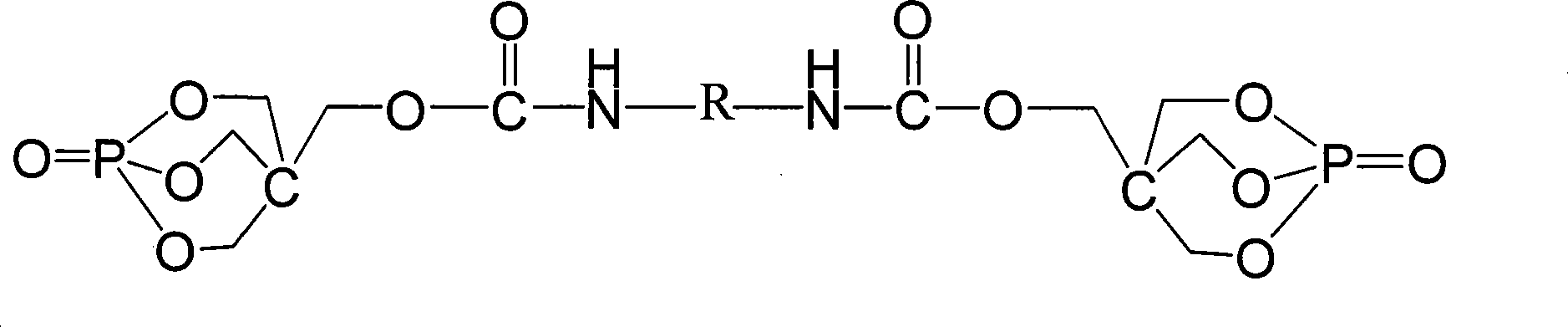

[0031] Add 3.60g of the white solid PEPA obtained from the above reaction into a 250ml round-bottomed flask equipped with a drying device, a pear-shaped separating funnel and a stirring device, add 100ml of DMF as a solvent, stir to dissolve the PEPA, and then add dropwise through the pear-shaped separating funnel 1.74g TDI, fully stirred, reacted for 2 hours, gradually a lig...

Embodiment 2

[0034] Add 2.72g of pentaerythritol and 150ml of dioxane to a 250ml round-bottomed flask equipped with a nitrogen inlet and outlet, a drying device, a pear-shaped separating funnel and a stirring device, stir well to dissolve the pentaerythritol, and use a pear-shaped separating funnel Add 3.06g of phosphorus oxychloride dropwise and react for 0.5h under stirring, a large amount of white precipitates are produced. Filter, wash twice with deionized water, then wash twice with acetone, and dry in vacuum for 24 hours to obtain a white powdery solid with a yield of 92%.

[0035] Add 3.60g of the white solid PEPA obtained from the above reaction into a 250ml round-bottomed flask equipped with a drying device, a pear-shaped separating funnel and a stirring device, add 100ml of DMF as a solvent, stir to dissolve the PEPA, and then add dropwise through the pear-shaped separating funnel 2. 50gMDI, fully stirred, reacted for 2h, a light yellow precipitate gradually formed, the product w...

Embodiment 3

[0037] Add 2.72g of pentaerythritol and 150ml of dioxane to a 250ml round-bottomed flask equipped with a nitrogen inlet and outlet, a drying device, a pear-shaped separating funnel and a stirring device, stir well to dissolve the pentaerythritol, and use a pear-shaped separating funnel 3.06g of phosphorus oxychloride was added dropwise and reacted for 5h under stirring, a large amount of white precipitates were produced. Filter, wash twice with deionized water, then wash twice with acetone, and dry in vacuum for 12 hours to obtain a white powdery solid with a yield of 96%.

[0038] Add 3.60g of the white solid PEPA obtained from the above reaction into a 250ml round-bottomed flask equipped with a drying device, a pear-shaped separating funnel and a stirring device, add 100ml of DMF as a solvent, stir to dissolve the PEPA, and then add dropwise through the pear-shaped separating funnel 2. 50g of MDI, fully stirred, reacted for 10 hours, a light yellow precipitate gradually form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com