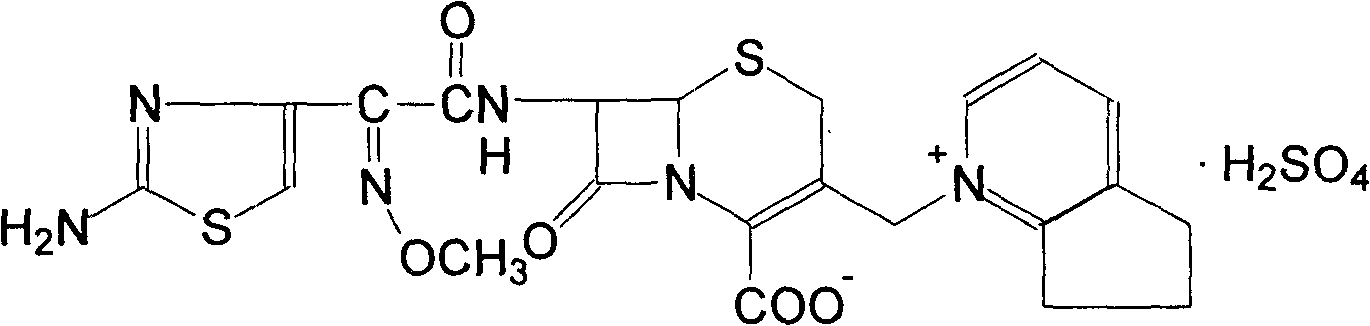

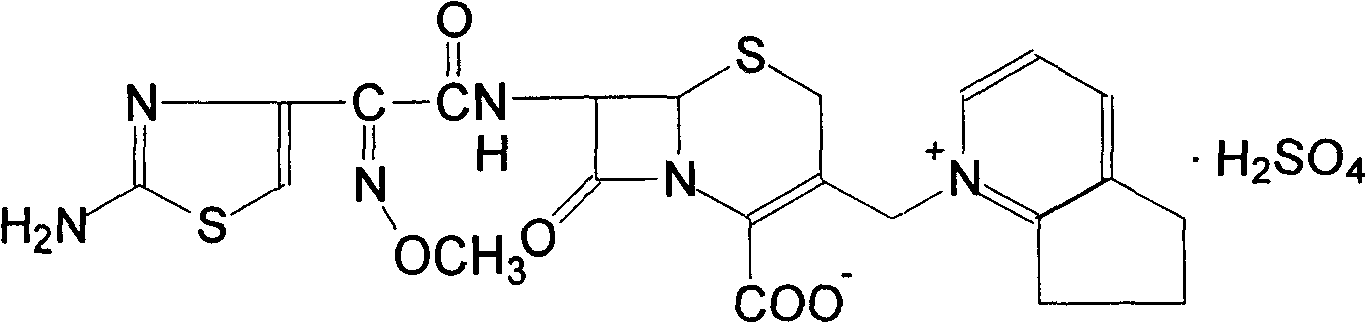

Method of preparing cefpirome sulfate

A technology of cefpirome sulfate and cefpirome, which is applied in the direction of organic chemistry, etc., can solve the problems of difficult three-waste treatment and large environmental pollution, and achieves the effects of reducing three-waste pollution, good product quality and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

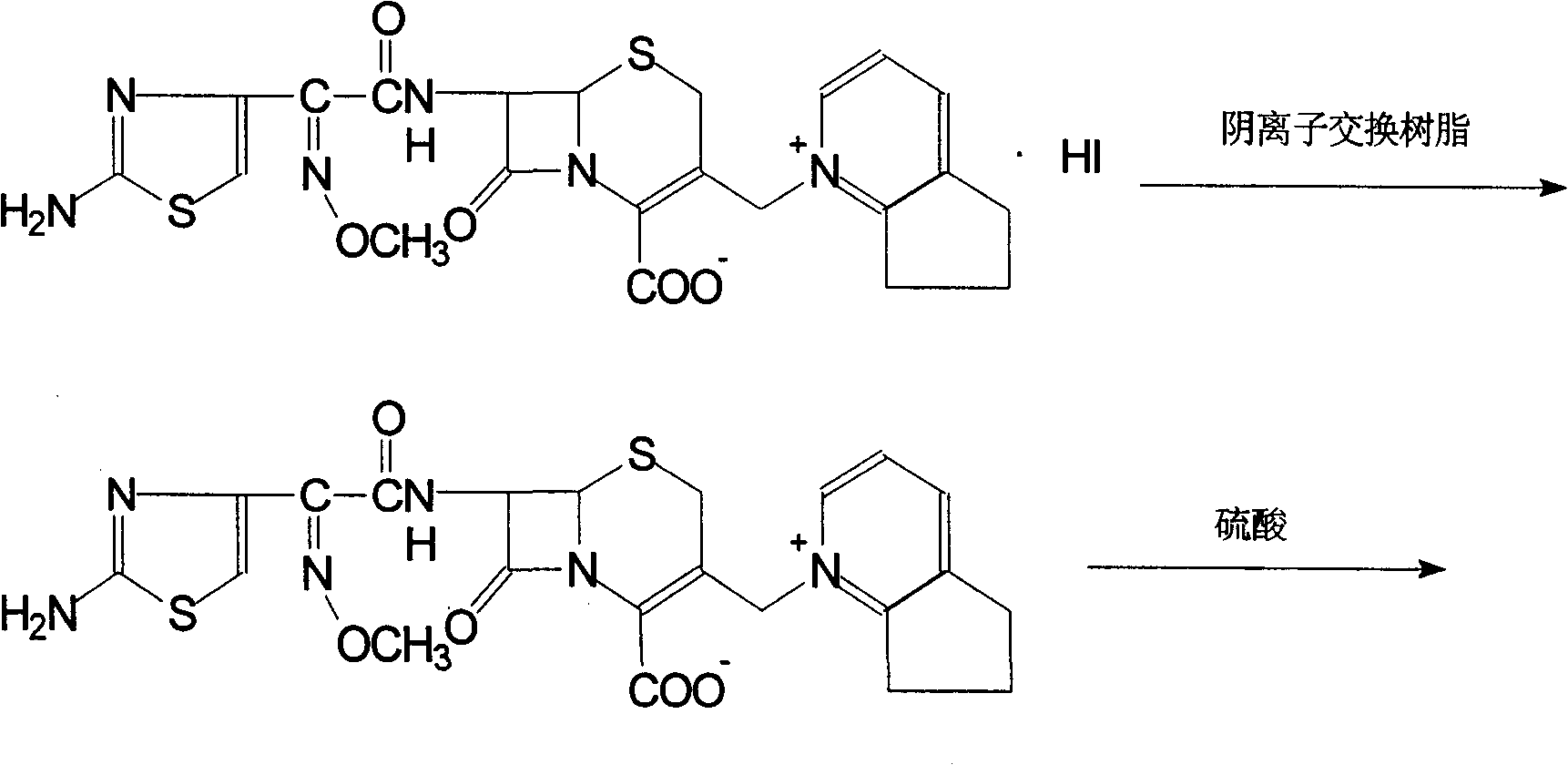

Method used

Image

Examples

preparation example Construction

[0021] Preparation of the test solution Take an appropriate amount of cefpirome test sample, add mobile phase to form a 0.5mg / ml solution, that is, too.

[0022] Preparation of reference substance solution Take an appropriate amount of cefpirome reference substance and add mobile phase to form a 0.005 mg / ml solution.

[0023] Determination method: Take 10 μl of the test solution and the reference solution respectively and inject them into the liquid chromatograph, measure and record the peak area, and calculate the content of the relevant impurities in the test according to the external standard method.

Embodiment 1

[0025] In a 100ml reaction bottle, add 10g of cefpirome hydroiodide, 30ml of pretreated 201×7 type strong basic anion exchange resin and 20ml of deionized water, stir at room temperature until the hydrogen iodide salt is completely dissolved, filter, and the filtrate Add 0.5g of activated carbon to the solution, stir for 30 minutes, filter, cool the aqueous solution to 5°C, adjust the pH to 1.3 with 6N sulfuric acid, then add dropwise cold ethanol, a white precipitate precipitates, keep stirring below 5°C for 2 hours, filter, and use cold ethanol After washing and vacuum drying, 5.5 g of off-white crystals were obtained. Yield 68.8%. Related substances: <2.0%

Embodiment 2

[0027] In a 100ml reaction bottle, add 10g of cefpirome hydroiodide, 40ml of pretreated D262 strong basic anion exchange resin and 30ml of deionized water, stir at room temperature until the hydrogen iodide salt is completely dissolved, filter, and add to the filtrate Activated carbon 0.5g, stirred for 35 minutes, filtered, cooled the aqueous solution to 5°C, adjusted the pH to 1.3 with 6N sulfuric acid, then added dropwise cold ethanol, a white precipitate precipitated, kept stirring below 5°C for 3 hours, filtered, washed with cold ethanol, After vacuum drying, 5.6 g of off-white crystals were obtained. Yield 70.0%. Related substances: <2.0%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com