Spinneret plate for melt spinning and preparation method thereof

A technology of melt spinning and spinneret, which is applied in the field of melt spinning spinneret and its preparation, which can solve the problems of polymer fiber filament change, spinneret hole surface damage, and fiber quality, etc., to achieve service life The effect of prolonging, reducing the scrap rate, and evenly distributing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

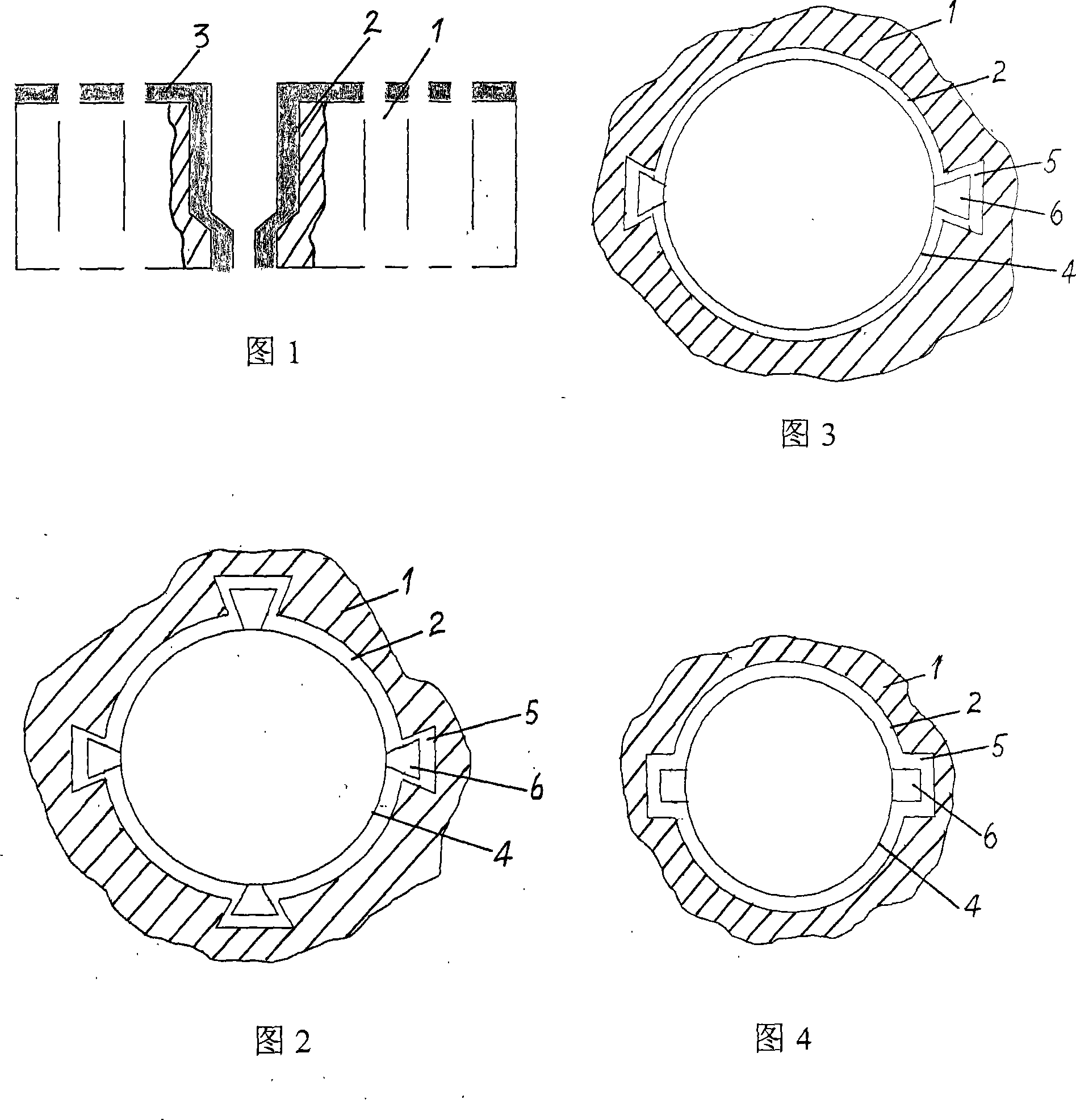

[0028] Add 3% polyethoxy monostearic acid herbal tea alcohol to the 1% polyvinyl alcohol aqueous solution, and stir evenly, and then add 0.8% of SiO with a particle size of 6nm. 2 Stir and mix the powder evenly to form a uniform and stable nano-suspension; immerse the spinneret in the prepared nano-suspension for 30 seconds, take it out, dry it naturally at room temperature, and then place the spinneret covered with the mixed film at 300 After processing in a high-temperature furnace at 1800°C for 30 minutes, place it in a heating furnace at 1800°C for 15 seconds, take it out and let the spinneret cool down slowly. In this way, the surface of the spinneret 1 including the spinneret hole 2 is coated with a layer of SiO with a thickness of about 0.8um. 2 Membrane 3, see Figure 1.

Embodiment 2

[0030] Add 5% polyethoxy monostearic acid herbal tea alcohol to the 10% polyvinyl alcohol aqueous solution, and stir evenly, then add 8% SiO with a particle size of 60nm 2Stir and mix the powder evenly to form a uniform and stable sub-nanometer suspension; immerse the spinneret in the prepared sub-nanometer suspension for 10 seconds, take it out, dry it naturally at room temperature, and then place the spinneret covered with the mixed film After processing in a high-temperature furnace at 240°C for 60 minutes, place it in a heating furnace at 1800°C for 30 seconds, take it out and let the spinneret cool down slowly. In this way, the surface of the spinneret 1 including the spinneret hole 2 is coated with a layer of SiO with a thickness of about 28um. 2 Membrane 3, see Figure 1.

Embodiment 3

[0032] Add 4% polyethylene oxide sorbitol monostearate to the 5% polyvinyl alcohol aqueous solution, and stir evenly, and then add 0.8% TiO with a particle size of 9nm. 2 Stir and mix the powder evenly to form a uniform and stable nano-suspension; immerse the spinneret in the prepared nano-suspension for 30 seconds, take it out, dry it naturally at room temperature, and then place the spinneret covered with the mixed film at 220 After processing in a high-temperature furnace at ℃ for 50 minutes, place it in a heating furnace at 1800 ℃ for 23 seconds, take it out and let the spinneret cool down slowly. In this way, the surface of the spinneret 1 including the spinneret hole 2 is coated with a layer of TiO with a thickness of about 12um. 2 Membrane 3, see Figure 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com