LaTiO3 evaporation material for high refractivity optical film, method of producing the same and use

A technology of high refractive index and optical thin film, which is applied in optics, optical components, instruments, etc., can solve the problems of increasing process difficulty and equipment investment, and achieve the effects of high transmittance, dense film layer and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: material preparation

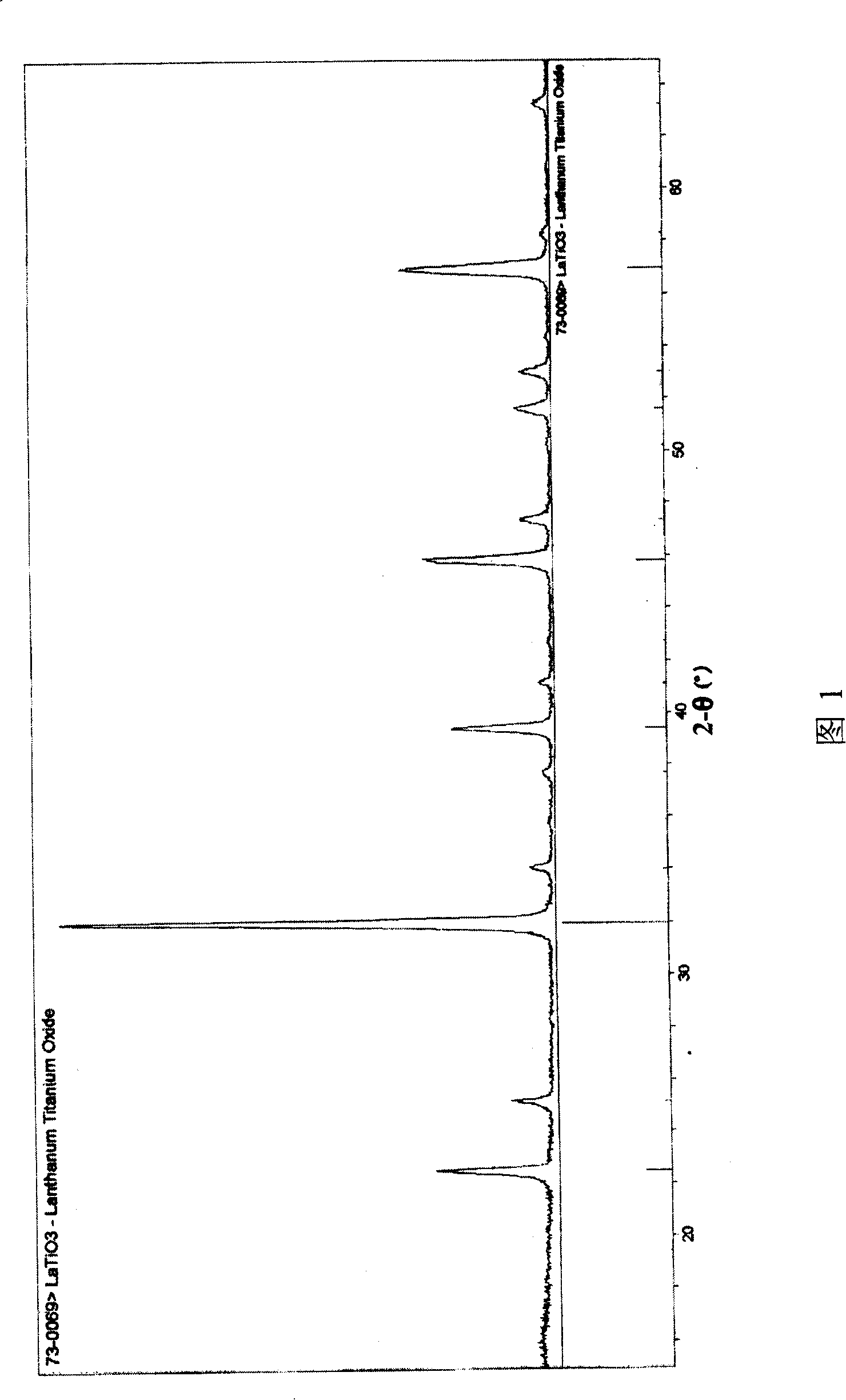

[0022] Ti 2 o 3 Fine powder and La 2 o 3 Mix thoroughly according to the weight ratio (3:7), grind and mix the mixture thoroughly for 4-6 hours, and press and granulate in an appropriate way, at 1700°C, vacuum degree: 2×10 -1 Pa-8×10 -2 Pa, keep warm for 3-8 hours and then cool down. Prepare a dark gray material with a density of about 5.3g / cm 3 , with a melting point of about 1800°C. The prepared high refractive index optical film uses LaTiO 3 The XRD pattern of the evaporated material is shown in Figure 1, and the XRD analysis shows that the material is composed of a single phase structure without other impurity phases.

Embodiment 2

[0023] Embodiment 2: material preparation

[0024] TiO 2 Fine powder, Ti powder and La 2 o 3 Mix thoroughly according to the weight ratio (70.3:6.7:23.0), grind and mix the mixture thoroughly for 4-6 hours, and press and granulate in an appropriate way, at 1700°C, vacuum degree: 2×10 -1 Pa-8×10 -2 Pa, keep warm for 3-8 hours and then cool down. Prepare a dark gray material with a density of about 5.5g / cm 3 , with a melting point of about 1800°C.

Embodiment 3

[0025] Example 3: Material Application

[0026] The substrate for coating is a quartz substrate, which is evaporated by electron beam evaporation equipment, and the vacuum degree is 1.5×10 -4 torr, the substrate temperature is 200°C, the evaporation temperature is about 2200°C, and the evaporation rate is , the refractive index of the prepared coating layer at 550nm is 2.11, the film layer is firm, and has no light absorption in the visible light region.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com