Method for preparing 3-chlorine-2-methyl-1-propylene

A technology of methyl propylene and methyl, which is applied in the field of preparing 3-chloro-2-methyl-1-propene, and achieves the effects of less side reactions, high yield and large product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

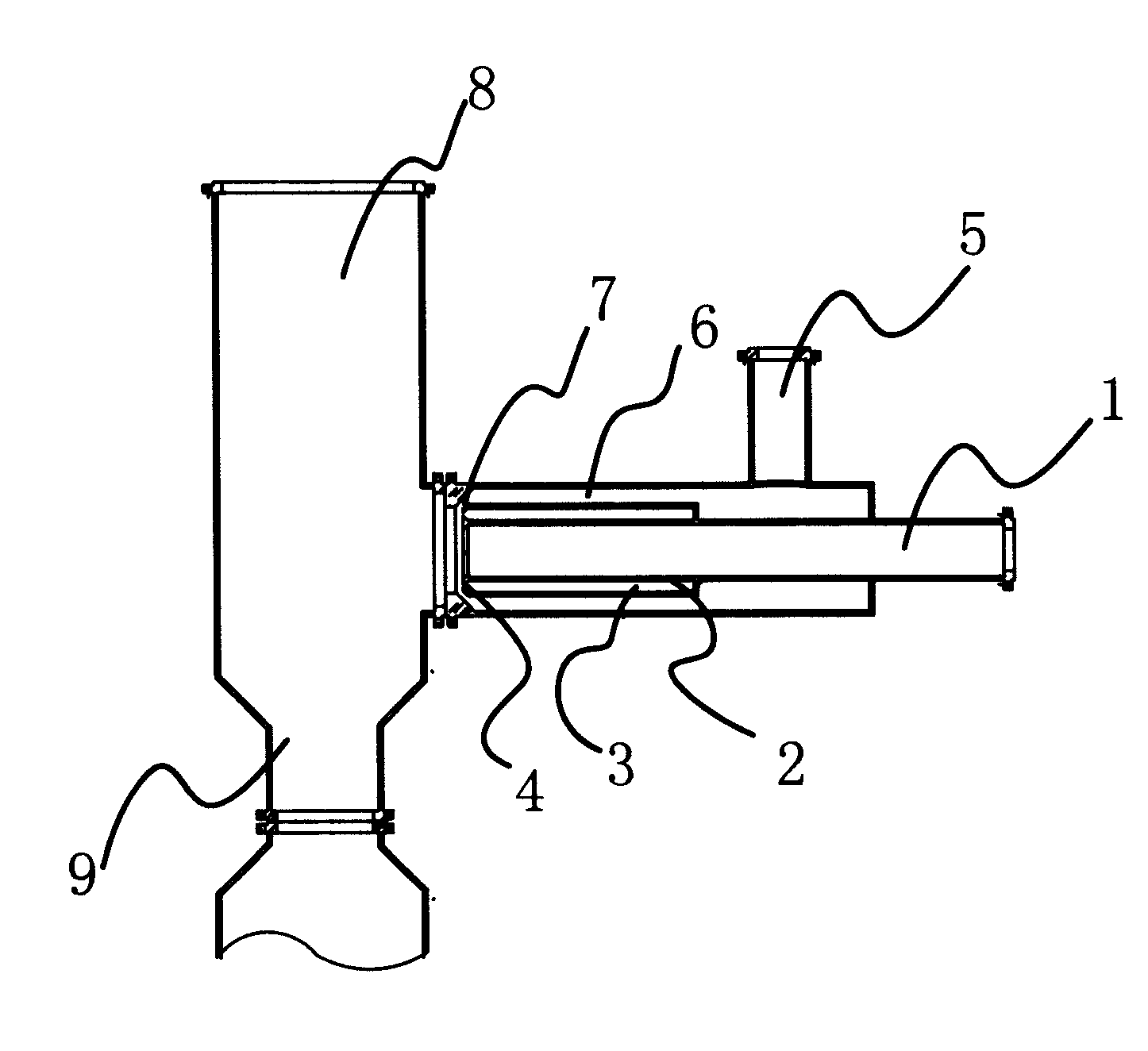

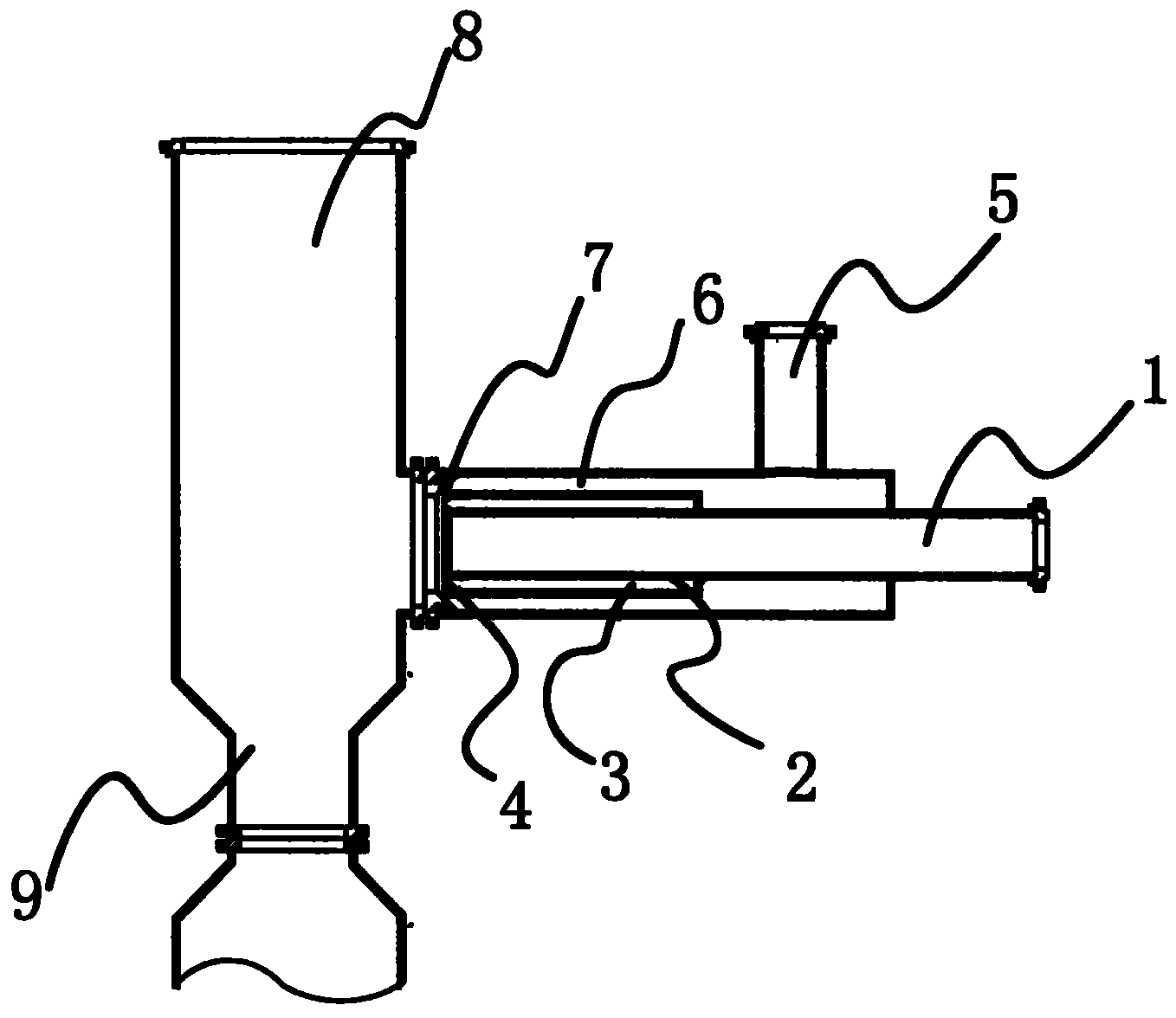

[0044] Embodiment 1: as figure 1 As shown, the present invention ensures enough time to complete the main reaction by adjusting the size of the reaction space, so that the light boiling chlorination side reaction is reduced to the minimum, and the reaction time is short enough (≤0.01s); the heat of reaction is required to be taken away quickly, reducing HCl The contact time with 2-methylpropene, the reaction product and chlorine gas can avoid the occurrence of side reactions of polychlorinated high boilers.

[0045] Such as figure 1 , a chlorination reaction device for preparing 3-chloro-2-methyl-1-propene from chlorine and 2-methylpropene, which includes a reactor A and a reaction system B. The chlorine gas feeding pipe 1 enters the outer pipe 3 through the porous side 2 of the pipe wall, and the outer pipe 3 has a conical nozzle 4 at the end, and the shape of the conical nozzle 4 is cylindrical; the 2-methacrylic feeding pipe 5 passes through the 2-methacrylic pipe 6 The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com