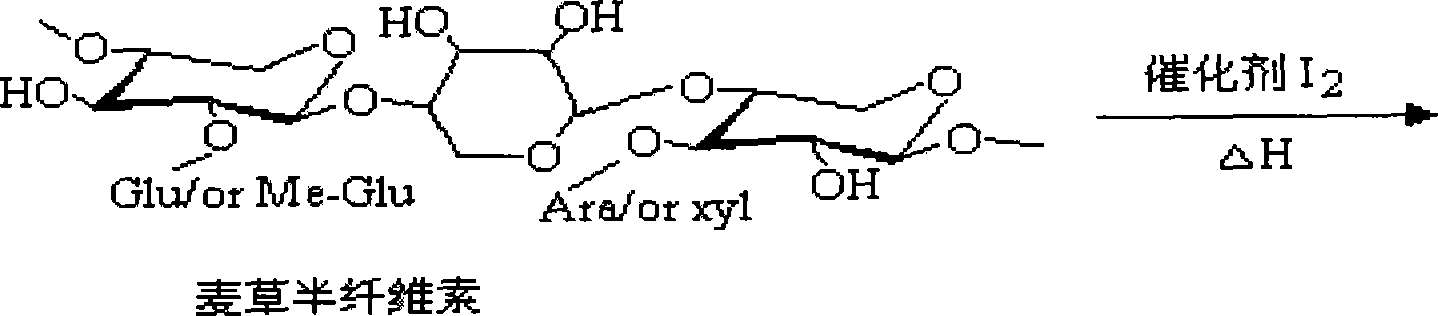

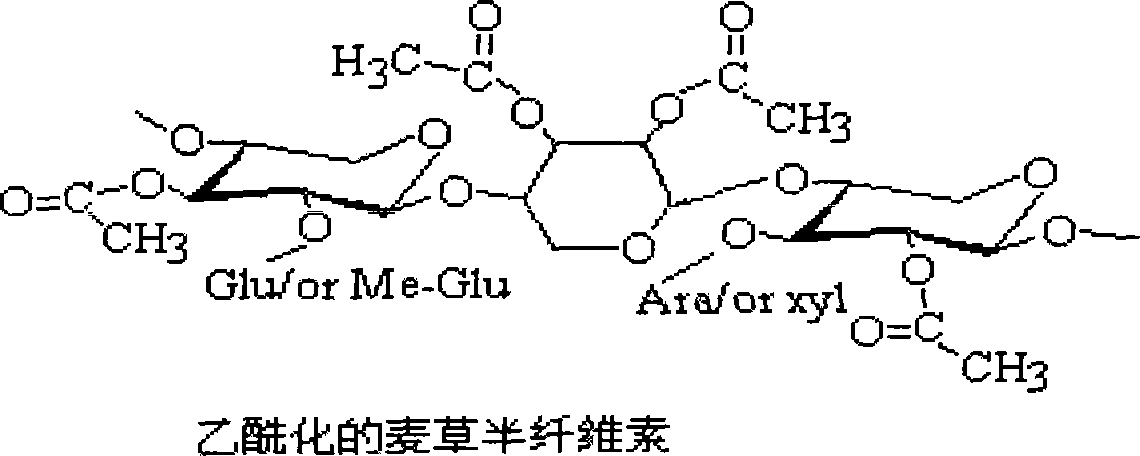

Method for preparing acetylated hemicellulose by employing catalysis of iodine

A technology for hemicellulose and catalytic preparation, applied in the field of modified hemicellulose, can solve problems such as toxicity and reduce production cost, and achieve the effects of improving hydrophobicity, reducing production cost and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In the first step, 50 g of ground wheat straw was first extracted with toluene-ethanol (2:1, v / v) in a Soxhlet extractor for 6 hours. Then add 1000ml of water and extract at 75°C for 2h to remove water-soluble hemicellulose. The residue was treated with 75 g of sodium chlorite in 1000 ml of water at 75° C. for 2 h (the pH value was adjusted between 3.6 and 3.8 with acetic acid). The solid-liquid ratio of delignified wheat straw and KOH solution is 1:20g·ml -1 Under the condition of 10wt% KOH at 23°C for 10h. The resulting filtrate was adjusted to pH 5.5 with 6 mol / l acetic acid, then precipitated with 3 volumes of 95% ethanol, filtered, washed with acidified 70% ethanol, air-dried for 12 hours and dried at 60°C for 16 hours.

[0026] In the second step, 6.6g of purified hemicellulose (equivalent to xylan hydroxyl mole in 0.1 hemicellulose composition) is placed in a 500ml three-necked reaction flask, and 260g of 1-butyl-3-methylimidazolium chloride ion is added Liqui...

Embodiment 2

[0031] In the first step, 50 g of ground wheat straw was first extracted with toluene-ethanol (2:1, v / v) in a Soxhlet extractor for 6 hours. Then add 1000ml of water and extract at 75°C for 2h to remove water-soluble hemicellulose. The residue was treated with 75 g of sodium chlorite in 1000 ml of water at 75° C. for 2 h (the pH value was adjusted between 3.6 and 3.8 with acetic acid). The solid-liquid ratio of delignified wheat straw and KOH solution is 1:20g·ml -1 Under the condition of 10wt% KOH at 23°C for 10h. The resulting filtrate was adjusted to pH 5.5 with 6 mol / l acetic acid, then precipitated with 3 volumes of 95% ethanol, filtered, washed with acidified 70% ethanol, air-dried for 12 hours and dried at 60°C for 16 hours.

[0032] In the second step, 6.6 g of purified hemicellulose (equivalent to 0.1 moles of xylan hydroxyl groups in hemicellulose composition) is placed in a 500 ml three-necked reaction flask, 260 g of ionic liquid is added, and the reaction is car...

Embodiment 3

[0036] In the first step, 50 g of ground wheat straw was first extracted with toluene-ethanol (2:1, v / v) in a Soxhlet extractor for 6 hours. Then add 1000ml of water and extract at 75°C for 2h to remove water-soluble hemicellulose. The residue was treated with 75 g of sodium chlorite in 1000 ml of water at 75° C. for 2 h (the pH value was adjusted between 3.6 and 3.8 with acetic acid). The solid-liquid ratio of delignified wheat straw and KOH solution is 1:25g·ml -1 Under the condition of 10wt% KOH at 23°C for 10h. The resulting filtrate was adjusted to pH 5.5 with 6 mol / l acetic acid, then precipitated with 3 volumes of 95% ethanol, filtered, washed with acidified 70% ethanol, air-dried for 12 hours and dried at 60°C for 16 hours.

[0037] In the second step, 8.8 g of purified hemicellulose (equivalent to 0.133 moles of xylan hydroxyl groups in the composition of hemicellulose) was placed in a 500 ml three-necked reaction flask, 260 g of ionic liquid was added, and the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com