Regeneratable load type desulfurizing agent and preparation method thereof

A supported, desulfurizing agent technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., to achieve the effects of simple preparation process, easy regeneration, and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Measure 1.5 grams of tetramethylguanidine lactate (TMGL for short) ionic liquid, add 10 milliliters of methanol, and mix well; 2 / g) Immerse in TMGL / methanol solution, stir to make it fully contact with the solution; then, volatilize at room temperature (about 30°C) for 1 hour, the silica gel is slurry; then heat the temperature to 45°C, volatilize for 4 hours At this time, the silica gel becomes powdery particles again; finally, the sample is heated in an oven at 80°C for 12 hours to fully remove methanol and possible moisture to obtain a silica gel desulfurizer loaded with TMGL. In the obtained desulfurizing agent, the mass ratio of TMGL to silica gel carrier is 0.5:1.

Embodiment 2

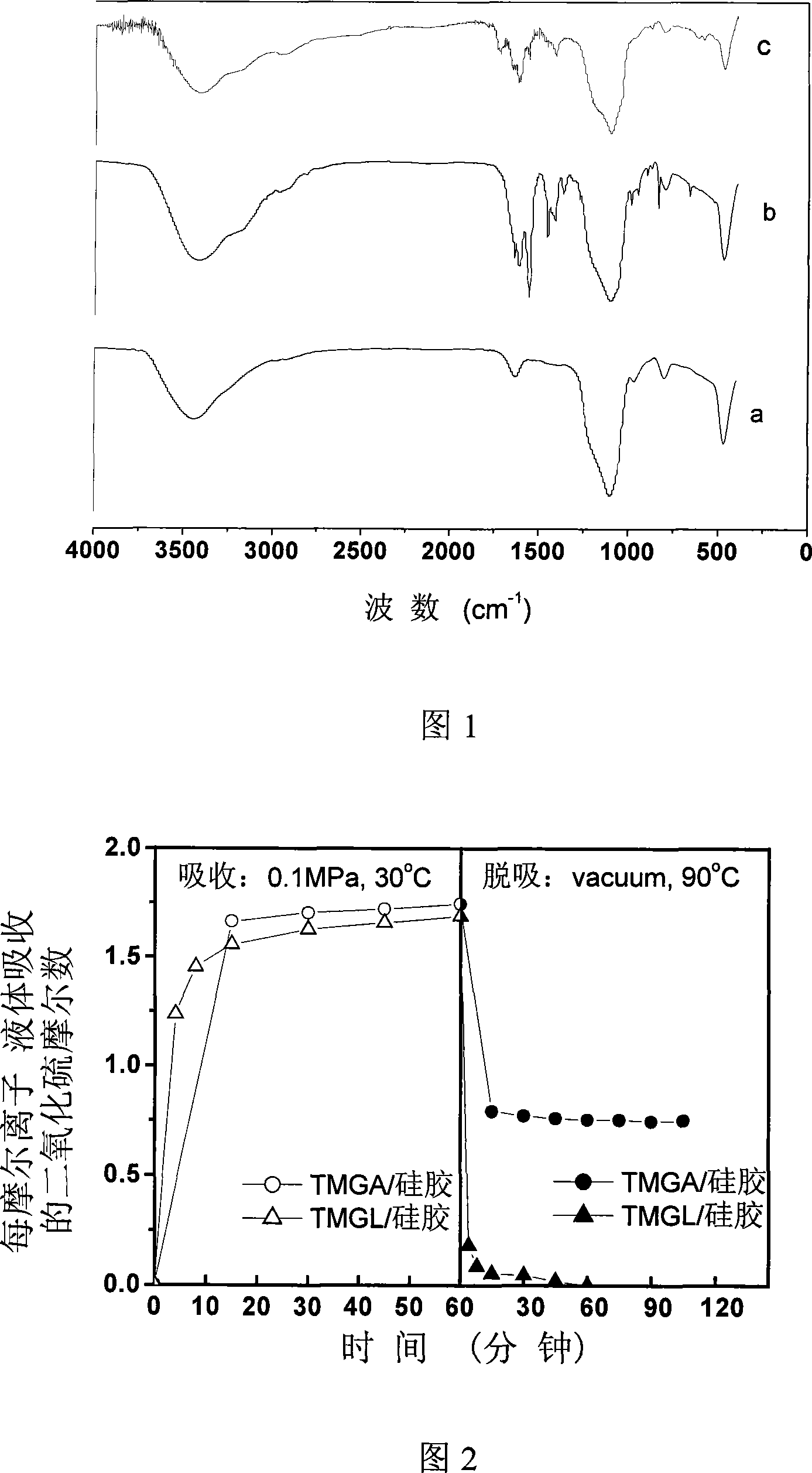

[0037] Measure 3 grams of tetramethylguanidine acrylate (abbreviated as TMGA) ionic liquid, add 10 milliliters of ethanol, mix well; immerse 3 grams of dry silica gel in the obtained solution, stir, make it fully contact with the solution; then, at room temperature ( Volatilize at about 30°C for 0.5 hours, and the silica gel is in the form of a slurry; then heat the temperature to 50°C and treat for 4 hours to make the solvent volatilize, at this time the silica gel becomes powdery particles again; finally put the sample into an oven at 80°C Heated for 12 hours to fully remove methanol and possible moisture to obtain a loaded desulfurizer loaded with TMGA ionic liquid. In the obtained desulfurizing agent, the mass ratio of TMGA to the silica gel carrier is 1:1. The infrared absorption spectra of silica gel, TMGA / silica gel desulfurizer and TMGA / silica gel desulfurizer after absorbing sulfur dioxide are shown in Figure 1.

Embodiment 3

[0039] Measure 3 grams of tetramethylguanidine acrylate (TMGA for short) ionic liquid and 0.01 gram of ammonium persulfate, add 10 milliliters of ethanol, and mix well; immerse 3 grams of dry silica gel in the resulting solution, stir to make it fully contact with the solution ; Then, volatilize at room temperature (about 30°C) for 0.5 hours, and the silica gel is in the form of a slurry; then heat the temperature to 50°C, and treat for 4 hours, while the solvent volatilizes and TMGA polymerizes, at this time the silica gel becomes powdery particles again Finally, put the sample into an oven at 80°C and heat it for 12 hours to fully remove methanol and possible moisture, and further polymerize TMGA to obtain a silica gel desulfurizer loaded with TMGA linear ionic polymer (PTMGA for short). In the obtained desulfurizing agent, the mass ratio of TMGA to the silica gel carrier is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com