Electric control optical switch array micro-fluidic chip manufacture method

A technology of microfluidic chips and optical switch arrays, applied in the coupling of optical waveguides, optics, optical components, etc., can solve the problems of limited switching capacity of optical switches, difficulty in making large arrays, etc., and achieve high speed performance, high Efficiency characteristics, effect of large switching capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

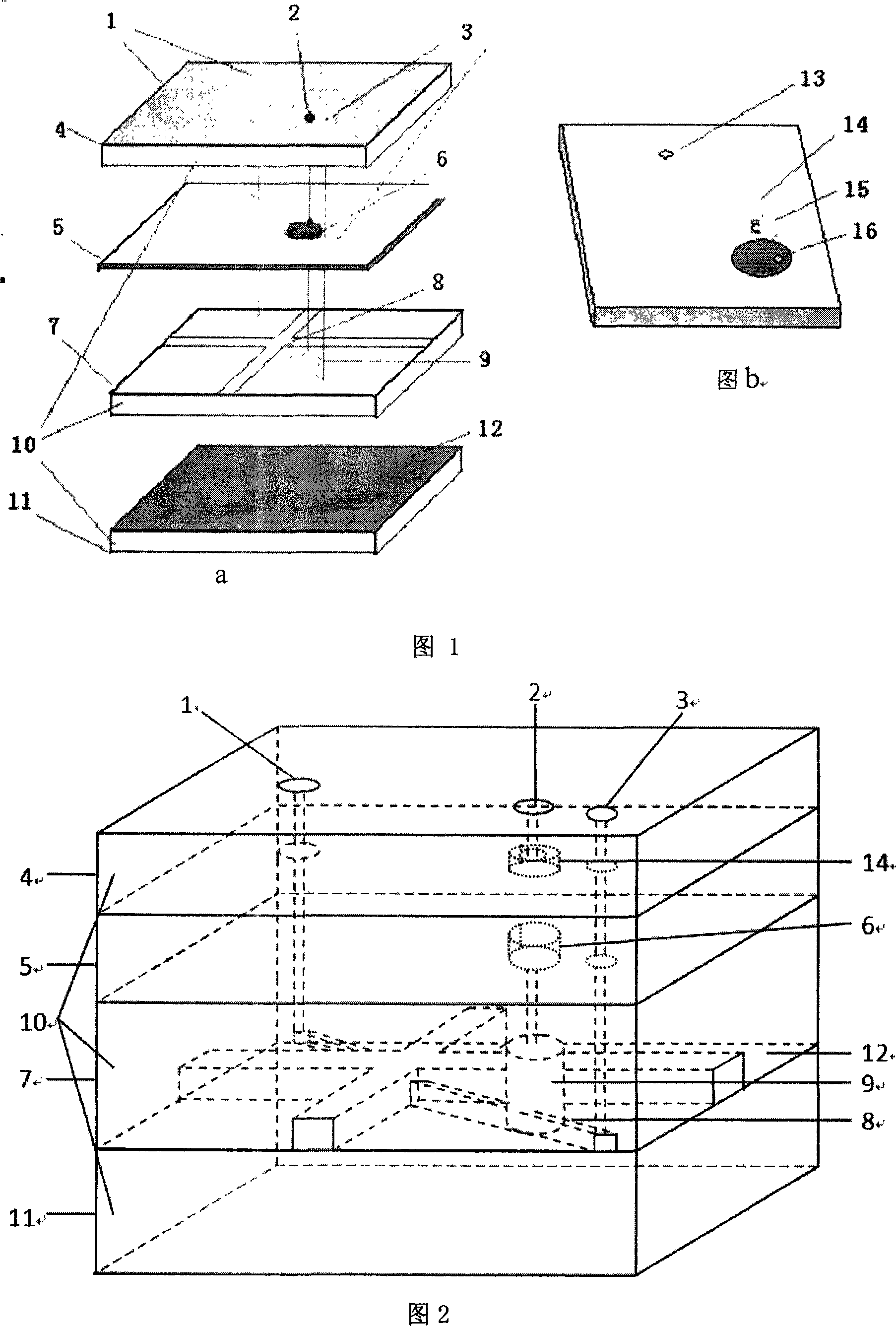

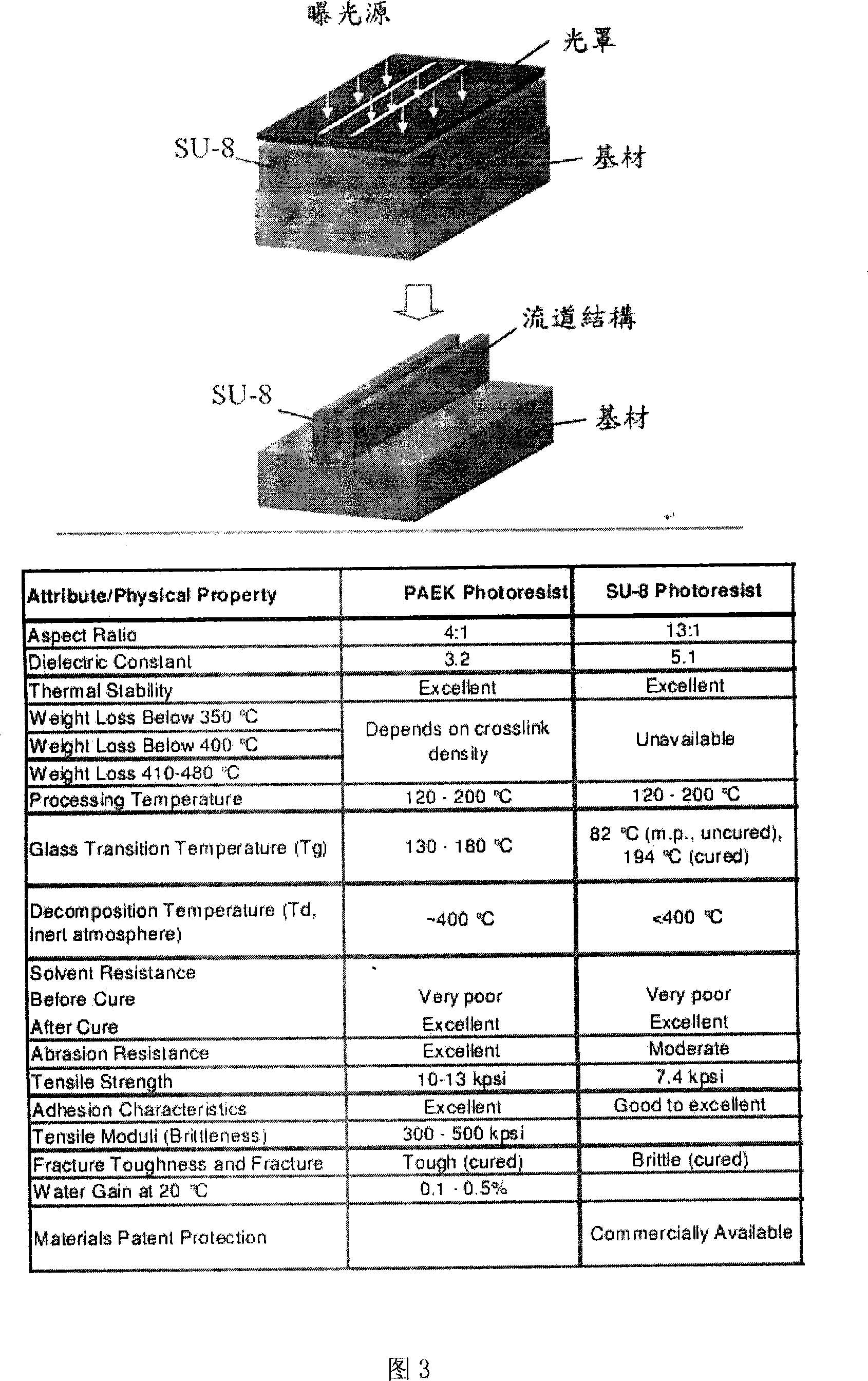

[0038]The invention proposes an array optical switch structure based on microfluidic technology, which adopts a sandwich structure of "optical waveguide layer + bottom conductive layer + insulating layer with conductive film block + upper cover plate". Wherein, the substrates of the cover plate, the optical waveguide layer and the bottom plate are polydimethylsiloxane (PDMS). PDMS has good light transmission, dielectric properties, inertness, non-toxicity, easy processing and other properties, and is cheap; the liquid in the micro-channels, thin tubes and liquid storage tanks on the optical waveguide layer is 201# methyl silicone oil. 201# methyl silicone oil has the characteristics of small temperature viscosity coefficient, high and low temperature resistance, anti-oxidation, high flash point, low volatility, good insulation, low surface tension, no corrosion to metal, and non-toxic; the insulating layer material is Polyvinyl alcohol (PVA) film. PVA film has good toughness,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com