Curable composition and substrates possessing protective layer obtained therefrom

A composition, functionalized technology, applied in the direction of coating, transportation and packaging, instruments, etc., to achieve the effect of less warping and low shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0048] Embodiment 1~3; Comparative example 1~3

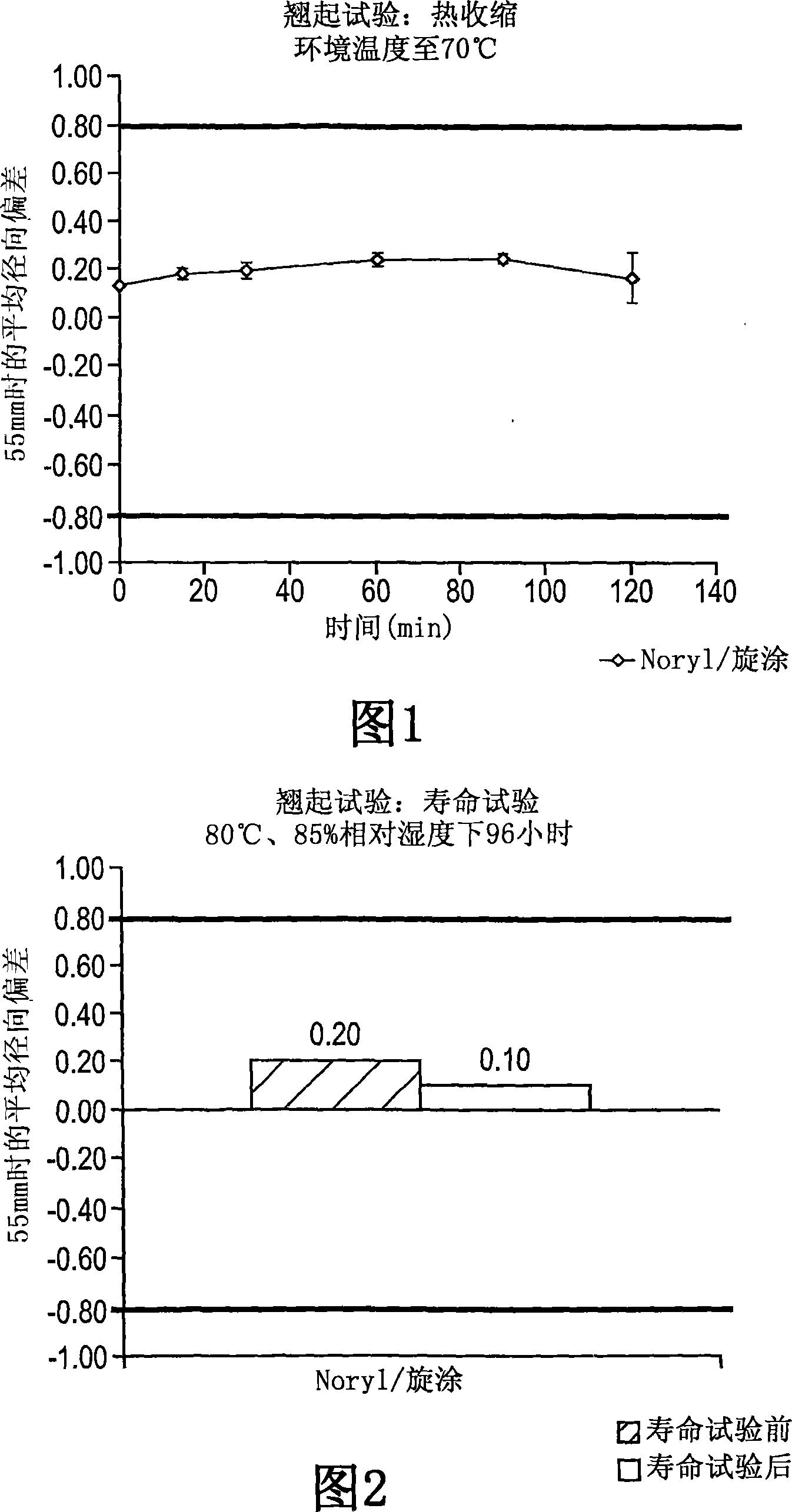

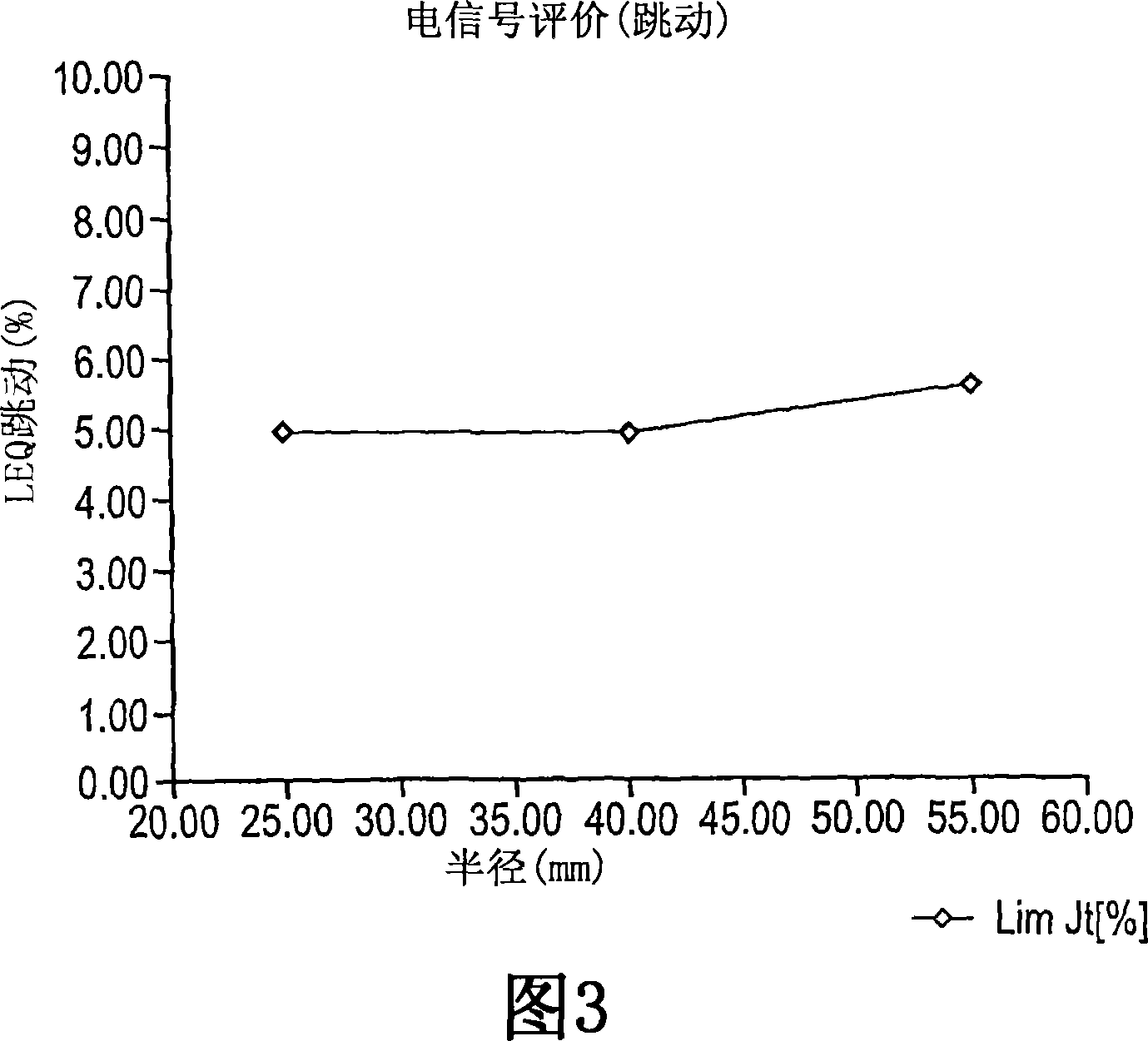

[0049] Examples 1 to 3 represent the preparation of curable compositions according to the invention, their application to discs made of PC (GE OQ1030) and GE Noryl (mixture of polyphenylene oxide (PPO) and polystyrene (PS)) and subsequent curing to provide a hard coating on the disc.

[0050] Comparative Examples 1-3 are provided for comparison purposes, showing that hardcoats prepared with urethane acrylates having more than 2 acrylate functional groups will be highly crosslinked on curing to cause layer cracking.

[0051] Observations of cracking or disc bending upon curing were recorded. Abrasion resistance was determined according to the Steel Wool Test described below. The test requires 11 front and back abrasions using a piece of steel wool (#0000) attached to the bottom of a 1 kg weight. The operator observes scratches on the surface. In some cases, a pencil hardness test according to ASTM test D3363 was also perform...

Embodiment 1

[0054] A mixture containing 365 g of isopropanol, 260 g of Nalco 1034 colloidal silica, 0.20 g of 4-hydroxy-TEMPO, and 39 g of methacryloxypropyltrimethoxysilane was refluxed for 3 hours while stirring to oxidize the colloidal Silicon (herein referred to as FCS 100) is functionalized and provides a predispersion. The predispersion was cooled to ambient temperature at which point 180 g of Dowanol PM and 116 g of tricyclodecane dimethanol diacrylate monomer (SR833S from Sartomer) were added to provide the final dispersion. The final dispersion was heated gently to about 80°C and placed on a rotavap. The isopropanol, water and Dowanol PM were removed under vacuum of less than 10 mmHg to provide a concentrated final dispersion. Gas chromatographic analysis confirmed the disappearance of volatiles therefrom. The TAInstrument Carri-Med Rheometer CSL 2 500 The viscosity at a shear rate of 10-100 l / s is about 2000 cps. Add photoinitiator Darocur 1173 to complete. 100 micron coat...

Embodiment 2 and 3

[0055] Embodiment 2 and 3; Comparative examples 1~3

[0056] In essentially the same manner as above, curable compositions were prepared with urethane diacrylate (Ebecryl 230), which was within the scope of the invention (Examples 2 and 3), and outside the scope of the invention with more than 2 acrylates Functional group urethane acrylate (Comparative Examples 1-3). The curable compositions of these examples were coated on discs, which were then cured essentially as described above.

[0057] The weight percent of FCS 100 and curable monomer in each curable composition, and the test results for the coated pans of Examples 1-3 and Comparative Examples 1-3, are shown in Table 1 below.

[0058] Table 1. Test results of 1100 micron coated discs

[0059] paint solution **

Coating thickness (μ)

burst

pencil hardness

Example 1

20l / s and 25℃

2000 cps

100 *

Do not

qualified

8H

Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com