Magnesium isoglycyrrhizinate freeze dried powder injection for injection and preparation method thereof

A technology of magnesium isoglycyrrhizinate and freeze-dried powder injection, which can be applied in freeze-dried delivery, medical preparations without active ingredients, and medical preparations containing active ingredients, etc. It is not conducive to large-scale production and other problems, and achieves the effects of easy transportation and long-term storage, small batch differences, and easy industrialized large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

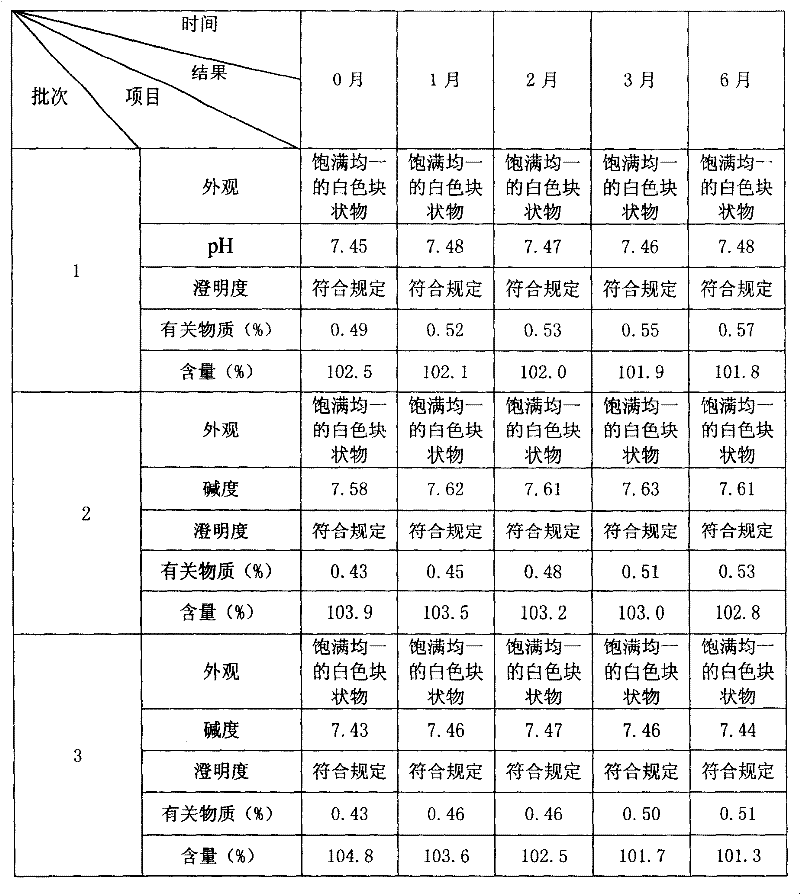

Image

Examples

Embodiment 1

[0027] Preparation formula:

[0028] formula

per bottle (mg)

1000 bottles (g)

Magnesium isoglycyrrhizinate

50

50

38

38

Add water for injection to

1ml

1000ml

[0029] The preparation method is as follows:

[0030] 1) Solution preparation

[0031] Dissolve disodium hydrogen phosphate in 800ml water for injection, add magnesium isoglycyrrhizinate, stir to dissolve.

[0032] 2) Removal of pyrogens

[0033] Heat to about 50°C, add 0.8g of activated carbon and stir for 15 minutes, cool to room temperature, and decarbonize by filtration. Take the filtrate and add water for injection to a sufficient amount, pass through a 0.22 μm filter membrane to obtain the intermediate.

[0034] 3) Packing

[0035] After the intermediates pass the inspection, they are divided into vials according to the content of the intermediates and half-pressed.

[0036] 4) freeze-dried

[0037] The eutectic poi...

Embodiment 2

[0039] Preparation formula:

[0040] formula

per bottle (mg)

1000 bottles (g)

Magnesium isoglycyrrhizinate

250

250

5

5

25

25

Add water for injection to

4ml

4000ml

[0041] The preparation method is as follows:

[0042] 1) Solution preparation

[0043] Dissolve sodium hydroxide in 3200ml water for injection, add magnesium isoglycyrrhizinate and lactose, stir to dissolve.

[0044] 2) Removal of pyrogens

[0045]Heat to about 50°C, add 10g of activated carbon and stir for 20 minutes, cool to room temperature, and decarbonize by filtration. Take the filtrate and add water for injection to a sufficient amount, pass through a 0.22 μm filter membrane to obtain the intermediate.

[0046] 3) Packing

[0047] After the intermediates pass the inspection, they are divided into vials according to the content of the intermediates and half-pressed.

[0048] 4) freeze-dri...

Embodiment 3

[0051] Preparation formula:

[0052] formula

per bottle (mg)

1000 bottles (g)

Magnesium isoglycyrrhizinate

50

50

108

108

glucose

200

200

Add water for injection to

4ml

4000ml

[0053] The preparation method is as follows:

[0054] 1) Solution preparation

[0055] Add ammonia water to 3200ml water for injection, stir evenly, add magnesium isoglycyrrhizinate and glucose, stir to dissolve.

[0056] 2) Removal of pyrogens

[0057] Heat to about 50°C, add 7.2g of activated carbon and stir for 30 minutes, cool to room temperature, and decarbonize by filtration. Take the filtrate and add water for injection to a sufficient amount, use G 6 Filter through a fused glass filter to obtain the intermediate.

[0058] 3) Packing

[0059] After the intermediates pass the inspection, they are divided into vials according to the content of the intermediates and half-pressed.

[0060] 4) fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com