Grease for hub bearings and hub bearing

A technology for wheel hub bearings and grease, applied in the directions of bearing elements, shafts and bearings, lubricating compositions, etc., can solve the problems of not achieving the improvement of the starting point peeling of the wheel hub bearing resistance surface, poor durability, weak surface strength, etc. The effect of starting point peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 3

[0090] Embodiment 1~Example 3 and Comparative Example 1~Comparative Example 3

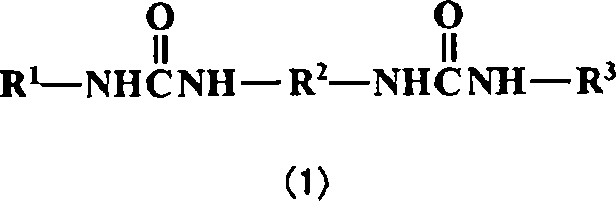

[0091] A mineral oil / urea base grease (JIS consistency No. 2 grade, consistency: 265 to 295) in which a urea compound as a thickener was uniformly dispersed in mineral oil as a base oil was prepared. Kinematic viscosity at 2000 g of mineral oil (Super Oil C manufactured by Nippon Oil Co., Ltd. at 40° C.): 100 mm 2 / sec), 193.5g of diphenylmethane-4,4'-diisocyanate, 82.8g of p-toluidine and 76.6g of cyclohexylamine were reacted to uniformly disperse the generated urea compound to obtain a basic lubricant fat. To this base grease, the additives shown in Table 1 were blended to obtain a grease for hub bearings.

[0092] In addition, 1 part by weight of sorbitan trioleate as an antirust additive, 1 part by weight of calcium sulfonate, and 2 parts by weight of alkyl diphenylamine as an antioxidant were added to 100 parts by weight of the above-mentioned lubricating grease for hub bearings. .

[0093...

Embodiment 4

[0095] A mineral oil / urea base grease (JIS consistency No. 2 grade, consistency: 265 to 295) in which a urea compound as a thickener was uniformly dispersed in mineral oil as a base oil was prepared. Kinematic viscosity at 2000 g of mineral oil (Super Oil C manufactured by Nippon Oil Co., Ltd. at 40° C.): 100 mm 2 / sec), react 149.5g of diphenylmethane-4,4'-diisocyanate, 64.0g of p-toluidine and 59.2g of cyclohexylamine to disperse the generated urea compound evenly, and obtain a basic lubricant fat. To this base grease, the additives shown in Table 1 were blended to obtain a grease for hub bearings.

[0096] In addition, 1 part by weight of sorbitan trioleate as an antirust additive, 1 part by weight of calcium sulfonate, and 2 parts by weight of alkyl diphenylamine as an antioxidant were added to 100 parts by weight of the above-mentioned lubricating grease for hub bearings. .

[0097] The obtained grease for hub bearings was evaluated in the same manner as in Example 1. ...

Embodiment 5

[0099] A mineral oil / urea base grease (JIS consistency No. 2 grade, consistency: 265 to 295) in which a urea compound as a thickener was uniformly dispersed in mineral oil as a base oil was prepared. Kinematic viscosity at 2000 g of mineral oil (Super Oil C manufactured by Nippon Oil Co., Ltd. at 40° C.): 100 mm 2 / sec), 309.2g of diphenylmethane-4,4'-diisocyanate, 132.4g of p-toluidine and 122.5g of cyclohexylamine were reacted to uniformly disperse the generated urea compound to obtain a basic lubricant fat. Additives shown in Table 1 were blended with this base grease to obtain a grease for hub bearings.

[0100] In addition, 1 part by weight of sorbitan trioleate as an antirust additive, 1 part by weight of calcium sulfonate, and 2 parts by weight of alkyl diphenylamine as an antioxidant were added to 100 parts by weight of the above-mentioned lubricating grease for hub bearings. .

[0101] The obtained grease for hub bearings was evaluated in the same manner as in Exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com