High-efficiency boiler for combustion of furol waste slag

A technology for burning furfural and waste residues, applied in steam boilers, fire tube steam boilers, sustainable manufacturing/processing, etc., to save equipment investment, reduce environmental pollution, and improve burnout rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

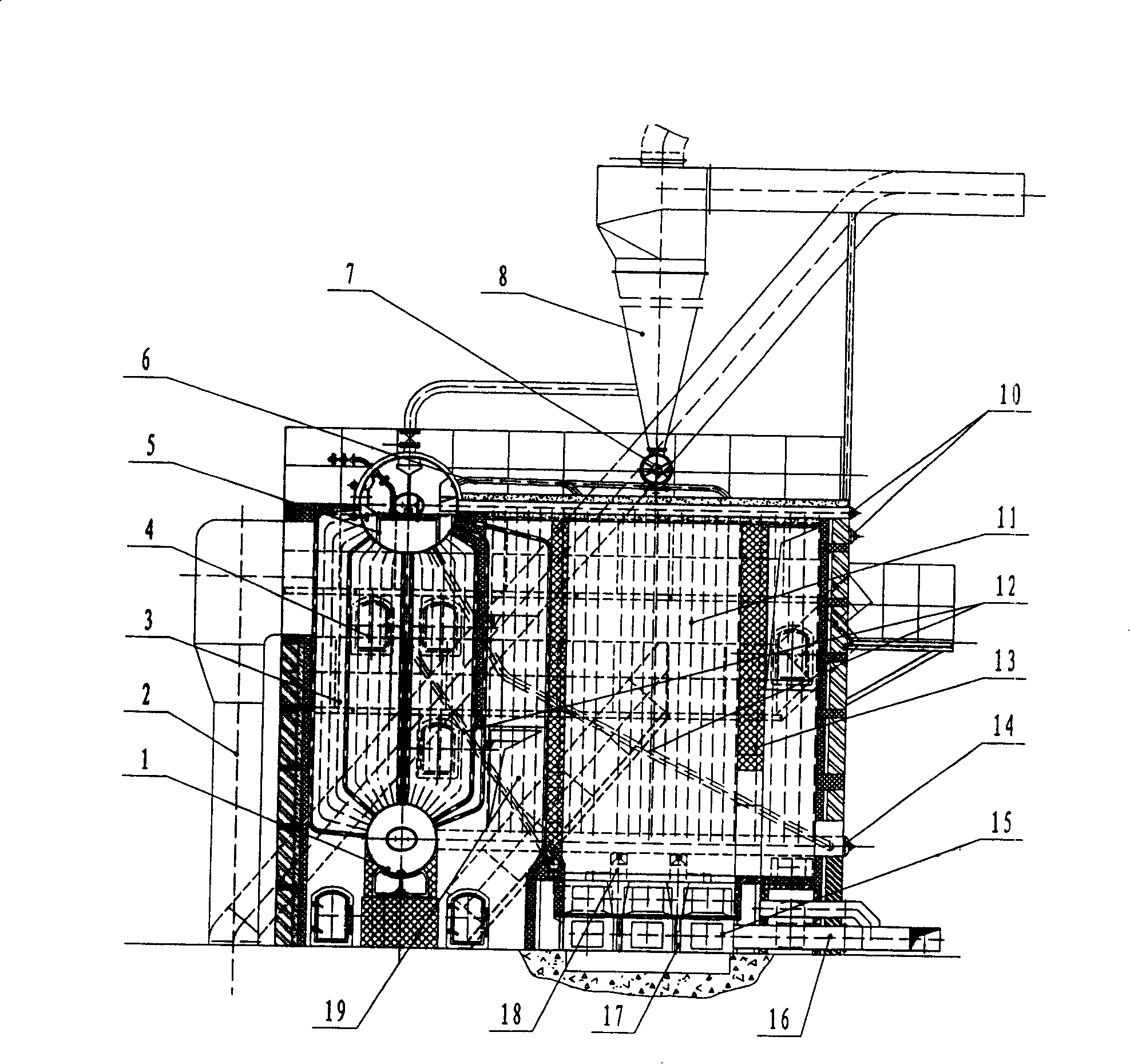

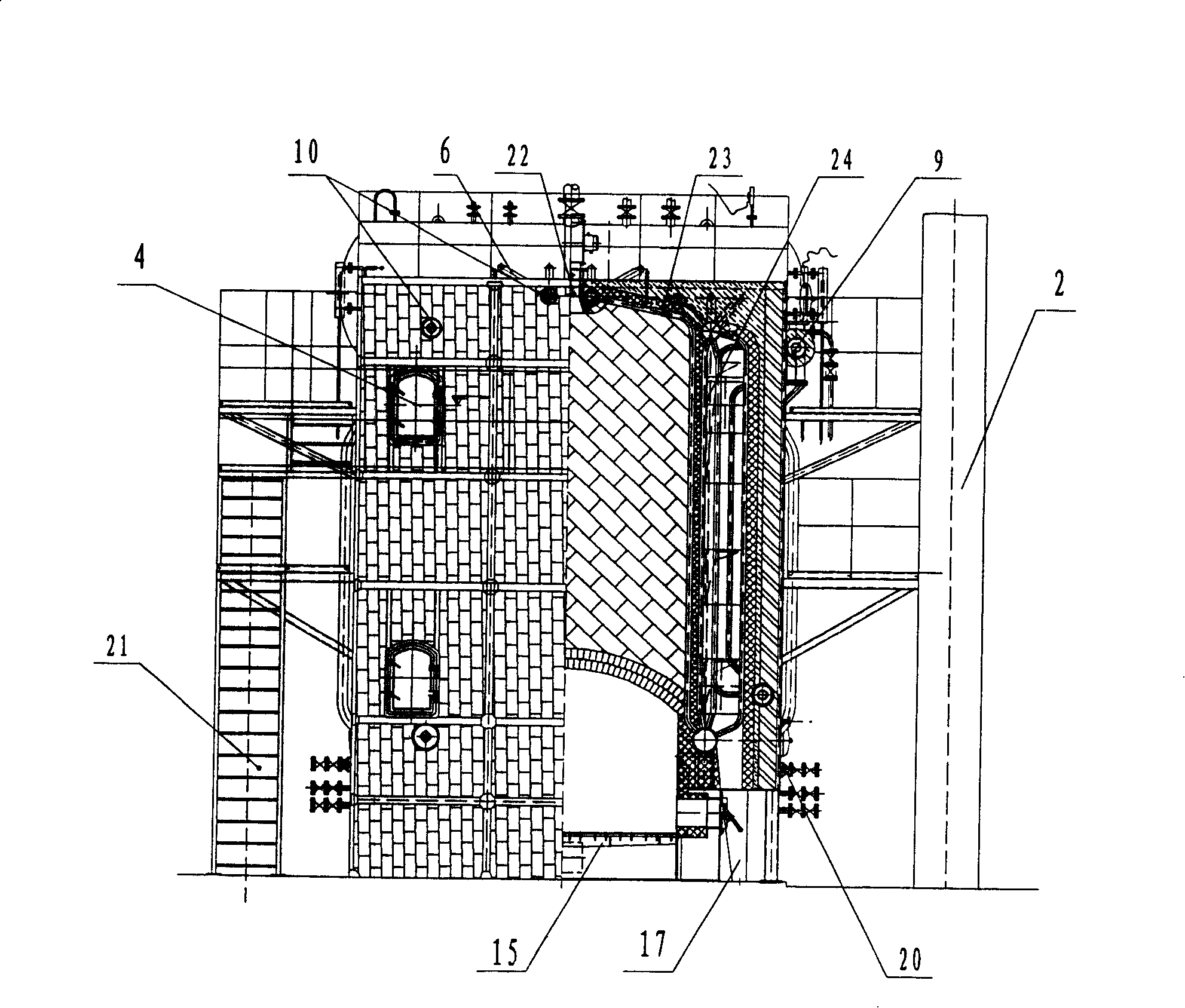

[0014] A high-efficiency furfural waste residue boiler as shown in the figure is a steam boiler with furfural waste residue as fuel. It is mainly designed for furfural industrial wastewater treatment. The steam it produces is not limited to furfural industrial wastewater treatment, but can also be used as a conventional industrial boiler. The furnace adopts a fixed grate 15. The bottom of the fixed grate 15 is a primary air supply port 16, and the top of the fixed grate 15 is a furnace 11. The four corners of the base of the furnace 11 are blocked during masonry to prevent uneven air distribution on the grate surface. The furnace 11 is a closed blast furnace with a small cross-sectional area. One corresponding side of the furnace 11 is the water cooling wall 23 connected with the upper and lower headers 10 and 14 , the other corresponding side is the furnace wall, and the shorter side of the furnace wall is the folded smoke wall 13 . The bottom of the furnace 11 is provided ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap