Method for producing polychloroethylene and hydrochloric acid

A technology of polyvinyl chloride and hydrochloric acid, applied in the preparation of sulfate/bisulfate, chlorine/hydrogen chloride, calcium/strontium/barium sulfate, etc., can solve the problems of restricting the development of PVC, achieve low cost, and solve environmental pollution problems , the effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach ( 2

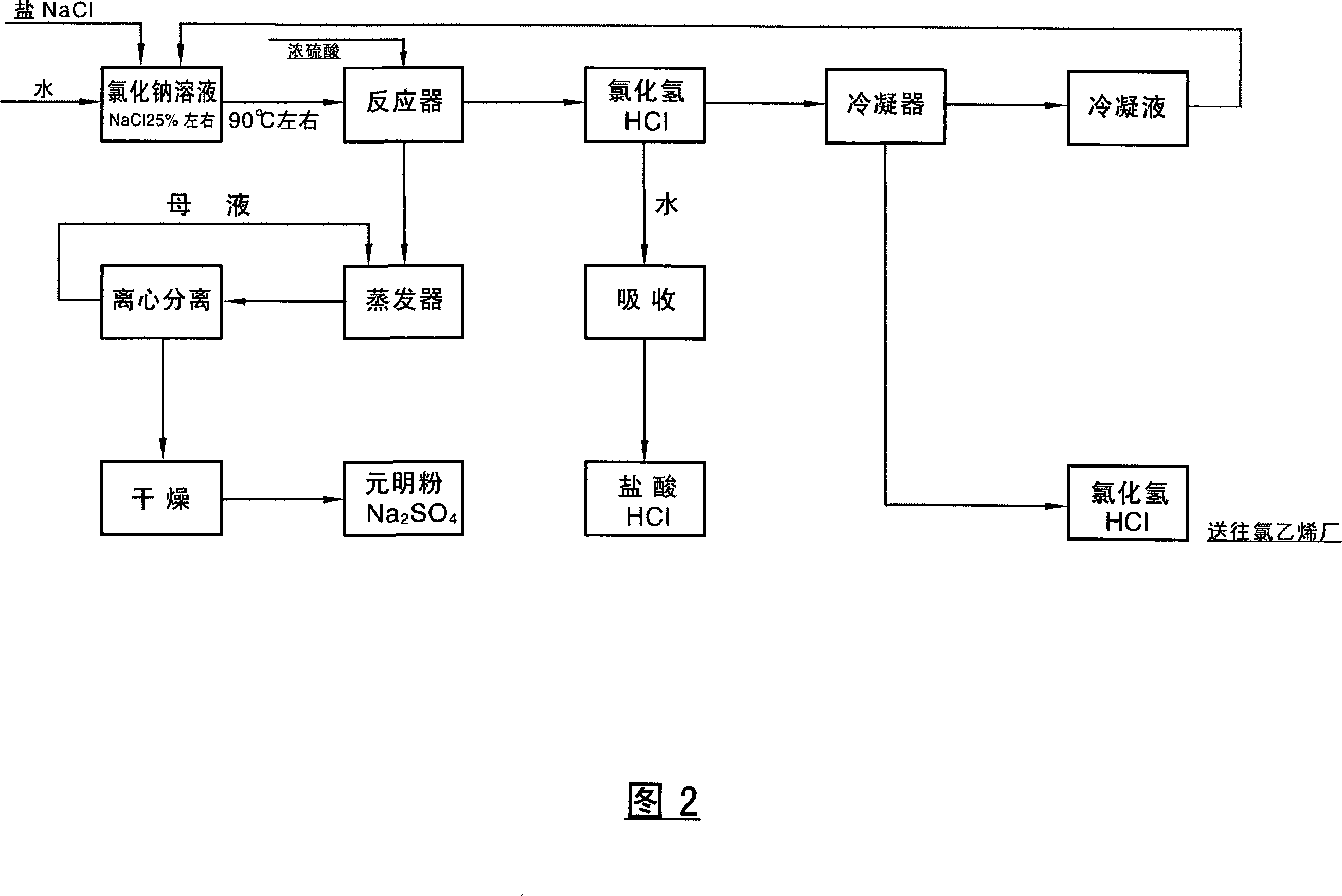

[0055] Where conditions are suitable, salt (NaCl) can also be used to produce hydrogen chloride, which can further produce PVC and hydrochloric acid. The process of producing hydrogen chloride is shown in Figure 2.

[0056] As shown in Figure 2, the salt (NaCl) is formulated into a solution of about 25%, and heated to about 90°C. Pour the salt solution into a stirred jacketed reactor heated by steam, gradually add preheated and slightly excessive concentrated sulfuric acid into the reactor, and at the same time turn on the mixer, and keep the reaction temperature at about 90°C.

[0057] After the reaction is completed, the reaction product sodium sulfate is in a supersaturated state, which is sent to the evaporator for further dehydration, and the resulting crystals are centrifuged and air-dried to make Yuanming powder. The centrifuge mother liquor is sent back to the evaporator to continue to evaporate.

[0058] HCl is extracted from the top of the reactor, and the entraine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com