Optical compensating sheet, polarizing plate, and liquid crystal display device

A technology of optical compensation sheet and polarizing plate, which is applied in optics, nonlinear optics, polarizing elements, etc., and can solve problems such as deterioration of optical characteristics, reduction of strength, and reduction of visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

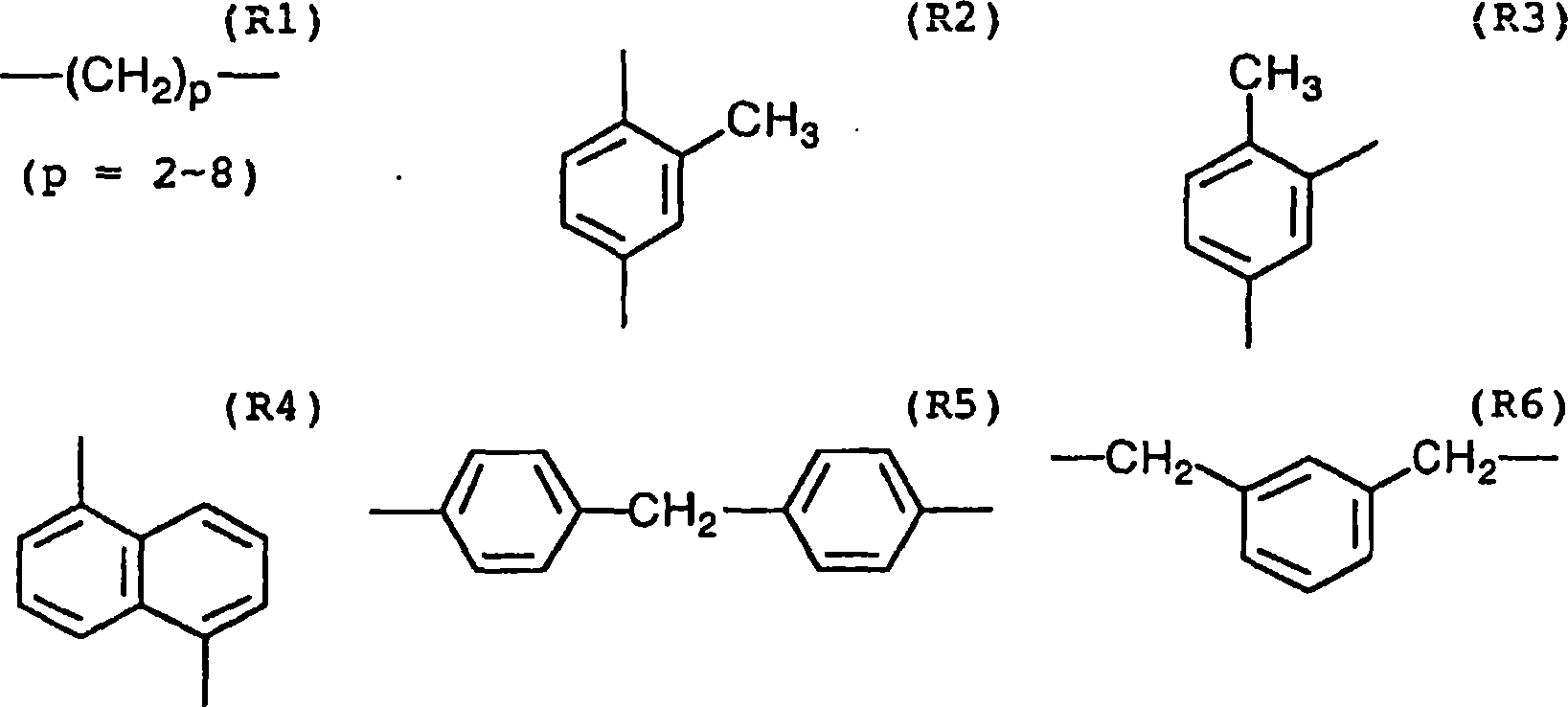

Method used

Image

Examples

preparation example Construction

[0349] Next, a method for producing a thin film using a coating liquid in the present invention will be described. The preparation method and equipment of the polymer film can use the currently known solution casting film forming method and solution casting film forming device called the cylinder method or the conveyor belt method for the preparation of the polymer film.

[0350] The film forming process will be described. The coating solution (cellulose acylate solution) prepared in the dissolver (tank) is temporarily stored in the storage tank, and the final preparation is performed to defoam the coating solution containing air bubbles. It is important to remove aggregates and foreign matter by precise filtration of the prepared coating liquid. Specifically, it is preferable to use a filter having a pore size as small as possible within a range in which components in the coating liquid are not removed. Filtration uses a filter with an absolute filtration precision of 0.1 to...

Embodiment 1

[0735] (Manufacture of cellulose acylate film)

[0736] The following composition was put into the mixing tank, and it stirred, heating, and each component was dissolved, and the cellulose acylate solution was prepared.

[0737] Composition of cellulose acylate solution

Cellulose acetate with a degree of acetylation of 60.9%

Triphenyl Phosphate (Plasticizer)

Diphenyl diphenyl phosphate (plasticizer)

Dichloromethane (1st solvent)

100 parts by mass

7.8 parts by mass

3.9 parts by mass

295 parts by mass

68 parts by mass

2 parts by mass

[0738] In another mixing tank, 16 parts by mass of the following delayed rising agent, 80 parts by mass of methylene chloride, and 20 parts by mass of methanol were charged and stirred while heating to prepare a delayed rising agent solution.

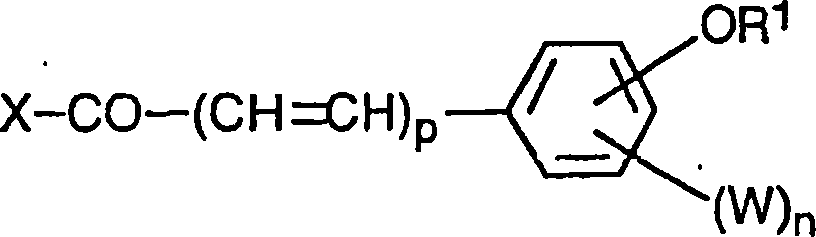

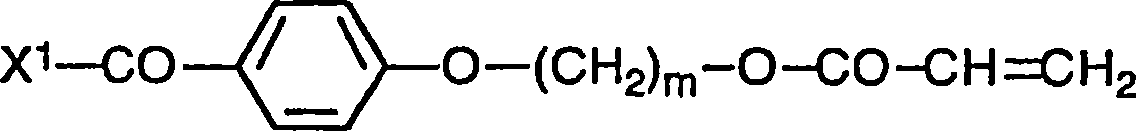

[0739] delayed ascension agent

[0740]

[0741] 474 part...

Embodiment 2

[0757] (Manufacture of cellulose acylate film)

[0758] The following composition was put into the mixing tank, and it stirred, heating, and each component was dissolved, and the cellulose acylate solution was prepared.

[0759] Composition of cellulose acylate solution

Cellulose acetate with a degree of acetylation of 60.7%

Polyether urethane (plasticizer)

100 parts by mass

16 parts by mass

(B-236, Sumitomo Bayer Ulettan Co., Ltd., Desmocol 176)

Dichloromethane (1st solvent)

Methanol (second solvent)

1-Butanol (the third solvent)

290 parts by mass

73 parts by mass

2 parts by mass

[0760] In another mixing tank, 16 parts by mass of the delayed rising agent used in Example 1, 80 parts by mass of methylene chloride, and 20 parts by mass of methanol were charged, stirred while heating, and a delayed rising agent solution was prepared.

[0761] 484 parts by mass of the cellulose acylate solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| In-plane retardation | aaaaa | aaaaa |

| Arithmetic mean roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com