Method for preparing polypropylene grafted copolymer

A polypropylene grafting and copolymer technology, which is applied in the field of graft copolymer preparation, can solve the problems of propylene coordination comonomer restriction, polar vinyl monomers are difficult to polymerize, etc., to improve the grafting effect , Simplify the preparation process and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

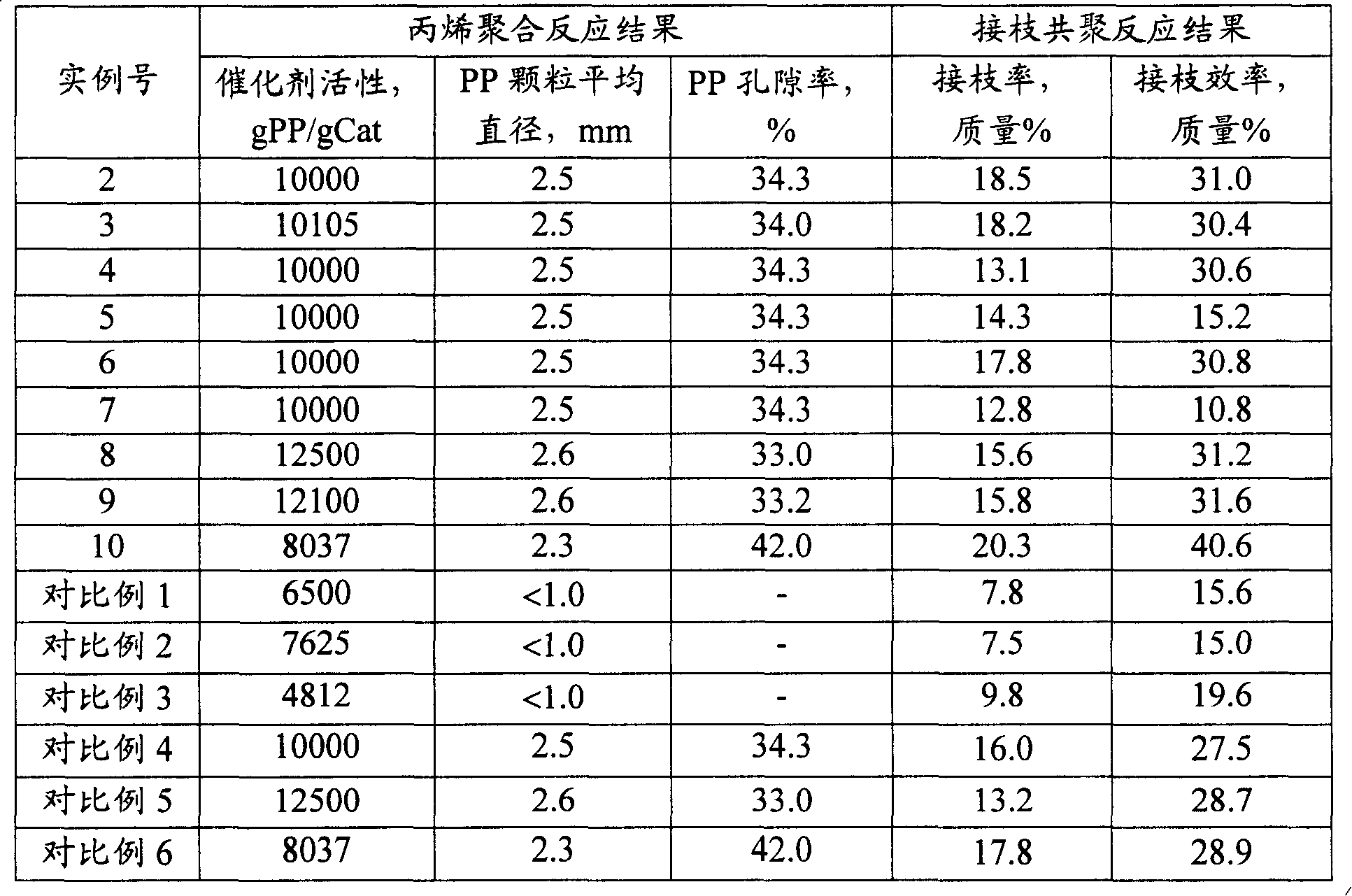

Examples

example 1

[0039] Prepare spherical carrier and polypropylene catalyst according to the method of CN1109067A.

[0040] (1) Preparation of carrier

[0041] Add 34g of anhydrous magnesium chloride, 80ml of absolute ethanol, 100ml of methyl silicone oil (chemically pure, with a viscosity of 300 centipoise), and 100ml of liquid paraffin (chemically pure, with a viscosity of 300 centipoise) to a stirrer equipped with nitrogen protection. In a 500ml reaction bottle with a condenser tube, heat to 120°C, react until the magnesium chloride is completely dissolved, transfer this solution to a mixed solution of 150ml each of methyl silicone oil and liquid paraffin, and stir at a speed of 2000 to 3000 rpm for 4 minutes, put it into anhydrous hexane pre-cooled to -30°C, stir until the system temperature rises to room temperature, filter, and wash the obtained solid three times with 200ml anhydrous hexane, and vacuum-dry to obtain a spherical carrier.

[0042] (2) Preparation of catalyst

[0043] Un...

example 2

[0045] The polypropylene graft copolymers described in the present invention are prepared.

[0046] (1) Propylene prepolymerization

[0047] Add 100ml hexane, 1.0g cocatalyst Al (C 2 h 5 ) 3 , 0.085g external electron donor - methylcyclohexyldimethoxysilane [CH 3 C 6 h 11 Si(OCH 3 ) 2 ] and 0.08g solid catalyst A, the molar ratio of aluminum / titanium is 300, and the molar ratio of external electron donor and titanium is 15. Propylene gas is passed into the reaction bottle at 20°C, and pre-polymerization is carried out under a pressure of 0.1MPa for 10 minutes. The mass ratio of the produced polypropylene to the catalyst A was 50.0. Most of the unreacted propylene in the solvent was removed under reduced pressure to obtain a propylene prepolymerized suspension.

[0048] (2) Propylene polymerization

[0049] Add 800ml of hexane into a 2L pressure-resistant stainless steel reactor with stirring, transfer the pre-polymerized suspension to the reactor, fill the reactor wi...

example 3

[0053] (1) Carry out propylene prepolymerization and polymerization in the same tank.

[0054] In a 2L pressure-resistant stainless steel reactor with stirring, add 800ml hexane, 1.0g promoter Al(C 2 h 5 ) 3 , 0.085g external electron donor [CH 3 C 6 h 11 Si(OCH 3 ) 2 ] and 0.08g of solid catalyst A, pre-polymerized for 10 minutes at 20°C under a propylene gas pressure of 0.1MPa, and the mass ratio of the resulting polypropylene to catalyst A was 50.0. Rapidly raise the temperature to 70° C., feed hydrogen and propylene to make the hydrogen pressure 0.1 MPa and the total pressure 0.9 MPa, and stir for 2 hours. The solvent and propylene in the reactor were removed under reduced pressure to obtain 808g polypropylene. The activity of the polymerization catalyst and the average diameter and porosity of the obtained polypropylene are shown in Table 1.

[0055] (2) Graft copolymerization

[0056] Get the undried polypropylene that (1) step makes, carry out polypropylene gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com