Method for manufacturing an SOI substrate

A manufacturing method and substrate technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as peeling or cracks, low melting point, and difficulties in joint surfaces, and achieve the effect of suppressing surface roughness and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

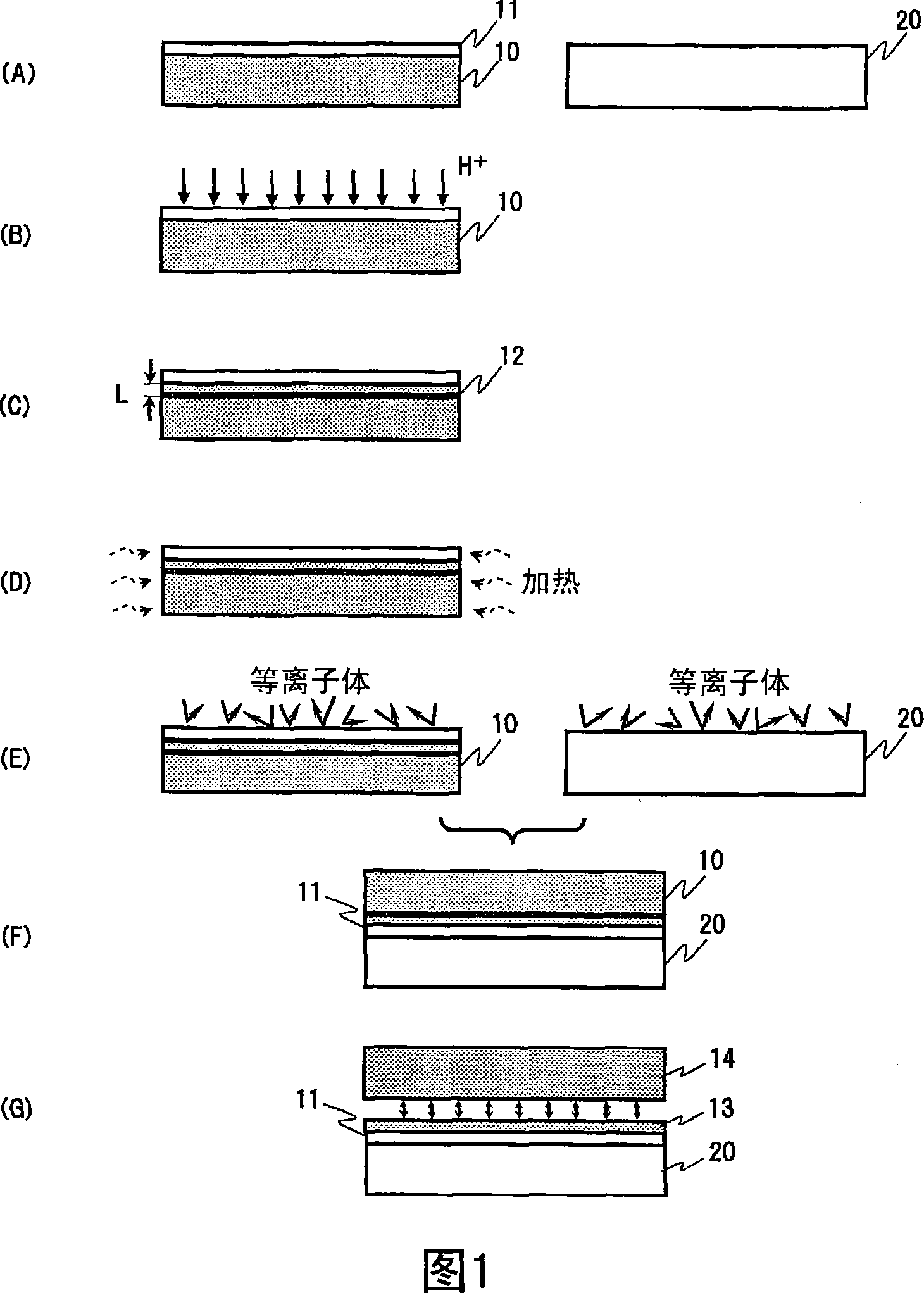

[0034] FIG. 1 is a diagram for explaining a process example of a method for manufacturing an SOI substrate of the present invention. In addition, in this embodiment, an oxide film is provided in advance on the surface of the silicon substrate, but this oxide film is not an essential configuration, and a general silicon substrate without an oxide film may be used.

[0035] The silicon substrate 10 shown in FIG. 1(A) is generally a single crystal silicon substrate; the supporting substrate is a quartz substrate 20 . Here, the single crystal silicon substrate 10 is, for example, a commercially available silicon substrate grown by the CZ method (Czochralski method), and its conductivity type, electrical characteristics such as resistivity, crystal orientation, crystal diameter, etc., It can be appropriately selected depending on the design value of the device, the process, or the representative area of the device to be manufactured (for the SOI substrate to be manufactured by th...

Embodiment 2

[0053] In this embodiment, the thickness of the oxide film formed on the main surface of the silicon substrate 10 is studied and discussed.

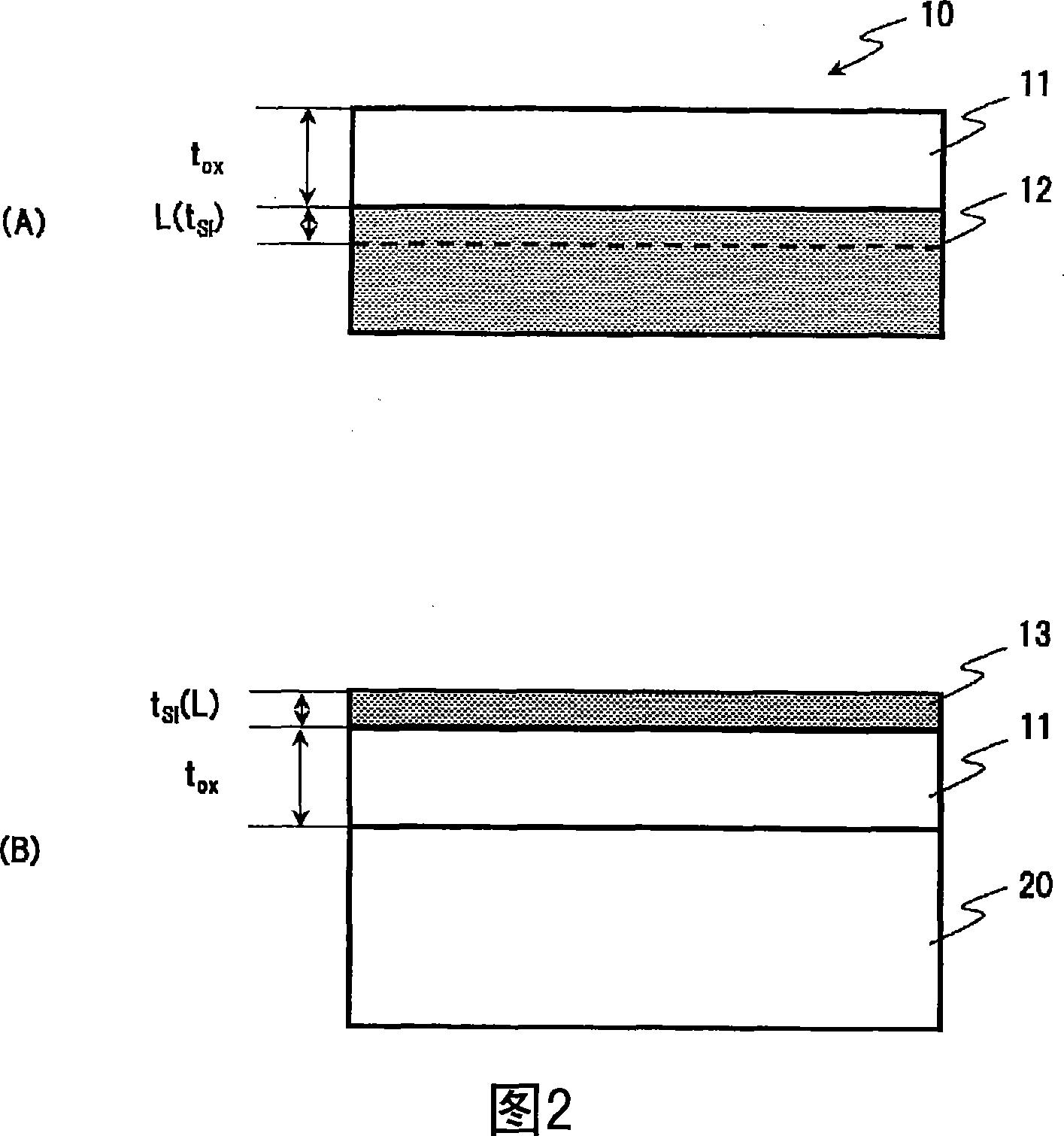

[0054] 2 is a cross-sectional view ( FIG. 2(A) ) for explaining a schematic shape of a bonding surface of a single-crystal silicon substrate used in the method for producing an SOI substrate of the present invention; and a silicon film having a silicon film obtained by peeling A schematic cross-sectional view of the SOI substrate (FIG. 2(B)).

[0055] As shown in FIG. 2(A) , a film thickness t is provided on one of the principal surfaces (bonding surfaces) of the single crystal silicon substrate 10 ox The silicon oxide film 11 is formed near the substrate surface, and the hydrogen ion implantation layer 12 is formed at the average ion implantation depth L. In this embodiment, in order to suppress the occurrence of transfer defects and slip dislocations in the peeling process of the silicon thin film after bonding with the quartz substra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com