Blind hole internal gear precision forming method and internal tooth forming mold

A technology for precision forming and internal gears, which is applied in the fields of metal stamping and metal machining. It can solve the problems of poor gear accuracy consistency, increased product structure, and low production efficiency, achieving good accuracy consistency, reducing product structure, and improving The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

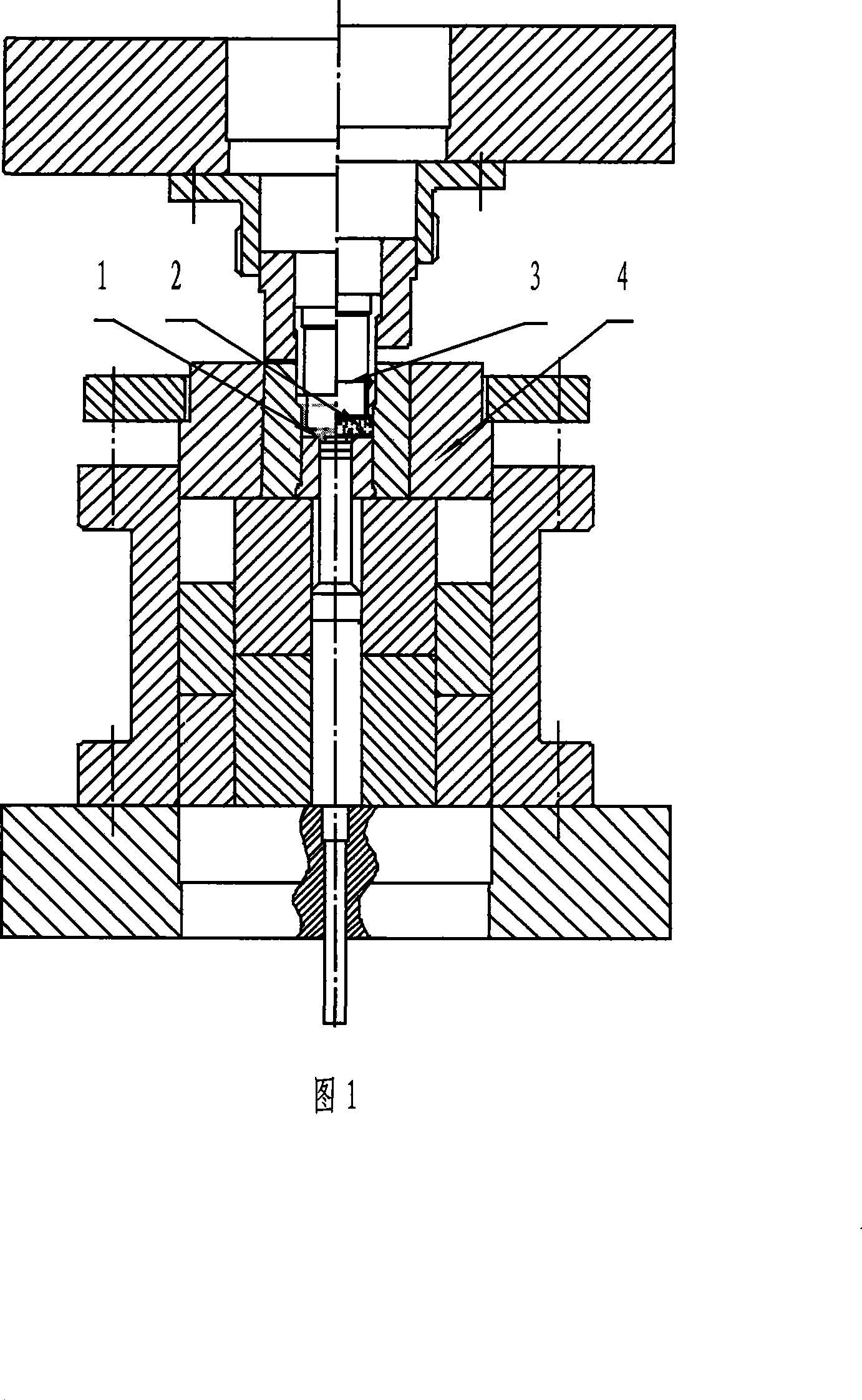

[0016] Take the JY60 internal gear made of 20 chromium manganese titanium material as an example.

[0017] The process steps of precision forming JY60 internal gear with 20 chromium manganese titanium material are as follows:

[0018] (1) Computer simulation analysis, drawing up a step-by-step forming scheme;

[0019] (2) Blank blanking;

[0020] ① Use 20 chromium manganese titanium round steel with a diameter of 65 mm, and the blanking weight is 476 grams;

[0021] ②The diameter of the blank (2) is turned to 64 mm;

[0022] (3) Surface softening and lubrication treatment;

[0023] ①Place the billet (2) in a heat treatment furnace, heat it to 770 degrees Celsius, keep it warm for 240 minutes for spheroidizing annealing, lower the furnace temperature to 550 degrees Celsius, and cool it in air, so that the hardness of the billet (2) is less than 85 trillion on the Rockwell B scale Pa;

[0024] ② Carry out shot blasting surface treatment to the blank (2);

[0025] ③ phospho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com