Ferulaic acid esterase activity detection method

A ferulic acid esterase and activity detection technology, applied in the field of enzyme engineering, can solve the problems of expensive equipment, time-consuming and laborious, complicated operation, etc., and achieve the effects of low sample consumption, high application value, and accurate experimental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

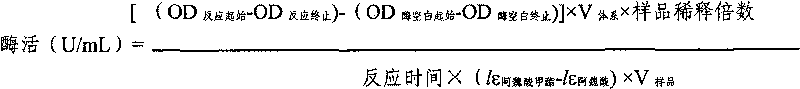

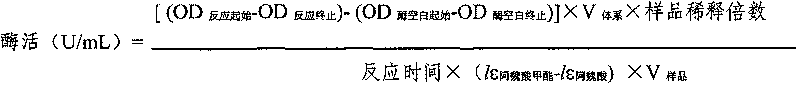

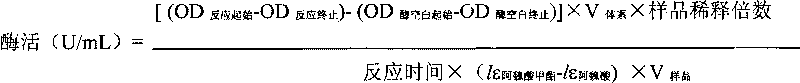

Method used

Image

Examples

Embodiment 1

[0033] The ferulic acid esterase activity detection method of the present invention is used to measure the daily change of the ferulic acid esterase activity in the rumen fluid of beef cattle.

[0034] (1) Weigh an appropriate amount of 104.11mg of methyl ferulate, fully dissolve it in 20ml of absolute ethanol, dilute it to 100μM with 100mM MOPS buffer (pH6.0), and preheat at 39°C for 15 minutes to obtain methyl ferulate solution;

[0035] (2) Add 100 μL of the enzyme solution to be tested diluted 6.25 times to each well of the 96-well plate, and preheat at 39°C for 15 minutes;

[0036] (3) Then, in the enzyme solution to be detected in step (2), add 200 μL of methyl ferulate solution in each of the 48 wells as a reaction system, and react at 39° C. for 30 minutes;

[0037] (4) Use a microplate reader to detect the OD value of the reaction system at the beginning and end of the reaction at 340nm;

[0038] 100mM MOPS buffer (pH6.0) was used to replace the methyl ferulate solu...

Embodiment 2

[0046] Utilize ferulic esterase activity detection method of the present invention to measure ferulic esterase activity in beef cattle rumen juice, specifically comprise the steps:

[0047] (1) Weigh 104.11mg of methyl ferulate, fully dissolve in 20ml of absolute ethanol, dilute to 50μM with 100mM MOPS buffer (pH4.5), preheat at 35°C for 30 minutes to obtain methyl ferulate solution ;

[0048] (2) Add 50 μL of the enzyme solution to be tested appropriately diluted 6 times to each well of the 96-well plate, and preheat at 35°C for 30 minutes to obtain the enzyme solution to be tested;

[0049] (3) In the enzyme solution to be tested in step (2), add 100ul of methyl ferulate solution in step (1) to each of the 48 wells, react at 35°C for 30 minutes, and use a microplate reader to detect the reaction system at 340nm OD value at the beginning and end of the reaction;

[0050] Replace methyl ferulate solution with 100mM MOPS buffer (pH6.0) as the enzyme blank, and add 100mM MOPS ...

Embodiment 3

[0054] Utilize ferulic acid esterase activity detection method of the present invention to measure ferulic acid esterase activity in the ferulic acid esterase preparation (Biocatalysts Co.Ltd, UK), specifically comprise the steps:

[0055] (1) Weigh 104.11mg of methyl ferulate, fully dissolve in 20ml of absolute ethanol, dilute to 200μM with 100mM MOPS buffer (pH7), preheat at 65°C for 10 minutes to obtain methyl ferulate solution;

[0056] (2) Add 100 μL of the enzyme solution to be tested appropriately diluted 1600 times to each well of the 96-well plate, add a total of 8 wells, and preheat at 65°C for 10 minutes to obtain the enzyme solution to be tested;

[0057] (3) In the enzyme solution to be tested in step (2), add 200ul of methyl ferulate solution in step (1) to each of the four wells, react at 65°C for 10 minutes, and use a microplate reader to detect the reaction system at 340nm OD value at the beginning and end of the reaction;

[0058] Replace methyl ferulate solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com