Coal and stone oil joint processing method for producing high quality engine fuel

An engine and petroleum technology, which is applied in the field of coal and petroleum co-processing technology, can solve the problems of increasing the coking tendency of heating equipment, reducing the proportion of pulverized coal, and unfavorable transportation, and achieves the improvement of product quality, reduction of secondary cracking, and reduction of production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

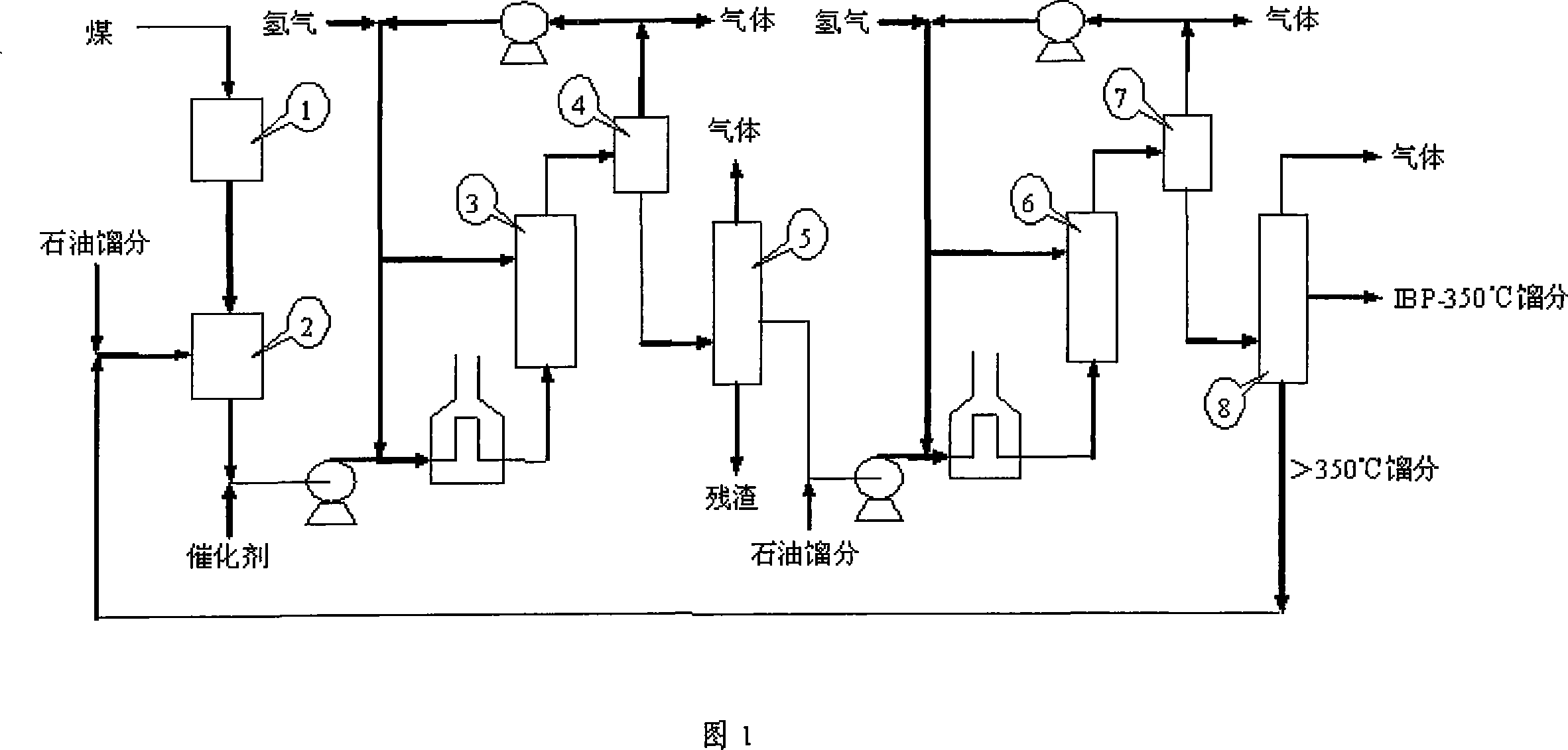

[0034] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. However, those skilled in the art can understand that the present invention is not limited to specific embodiments.

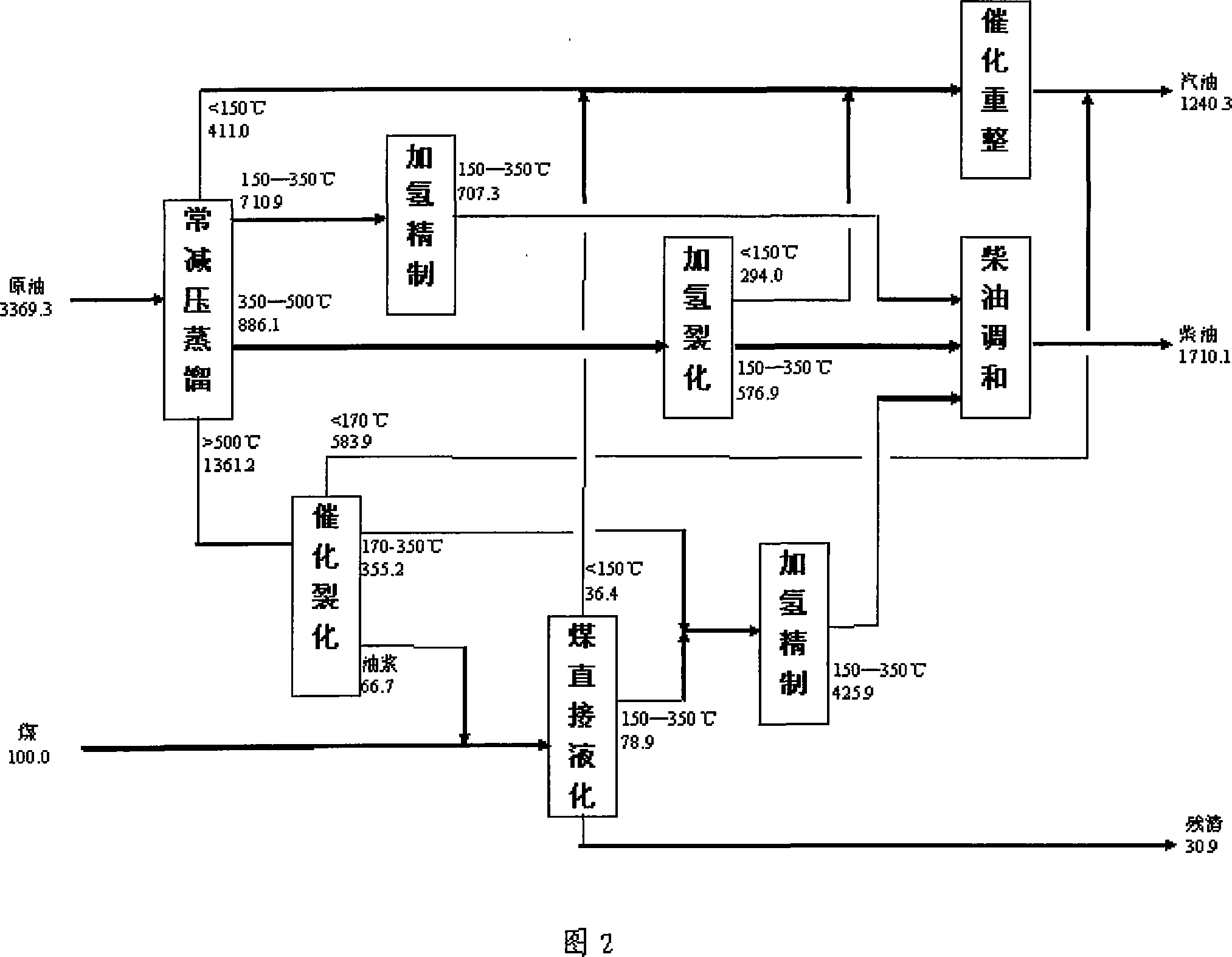

[0035] The characteristics of the process of direct coal liquefaction to directly produce fuel oil: (1) The content of aromatics in the liquefied oil is high, the cetane number of diesel oil is low, and the sulfur content is low. In order to increase the cetane number of diesel oil, it is usually necessary to selectively hydrocrack the produced oil, but this leads to a decrease in liquid product yield, an increase in gas yield, and an increase in hydrogen consumption, which reduces product output and increases processing costs. Even so, the cetane number of diesel can only be increased to about 40, and it is impossible to produce products that meet the current automotive diesel standards (requiring a cetane number higher tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com