Paint for transparent film and transparent film coated substrate

A film and transparent technology, applied in coatings, instruments, optics, etc., can solve the problems of inability to form particle layers, low bright room contrast, no anti-glare performance, etc., to achieve good productivity and economy, good strength, Good effect of anti-reflection performance and anti-glare performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

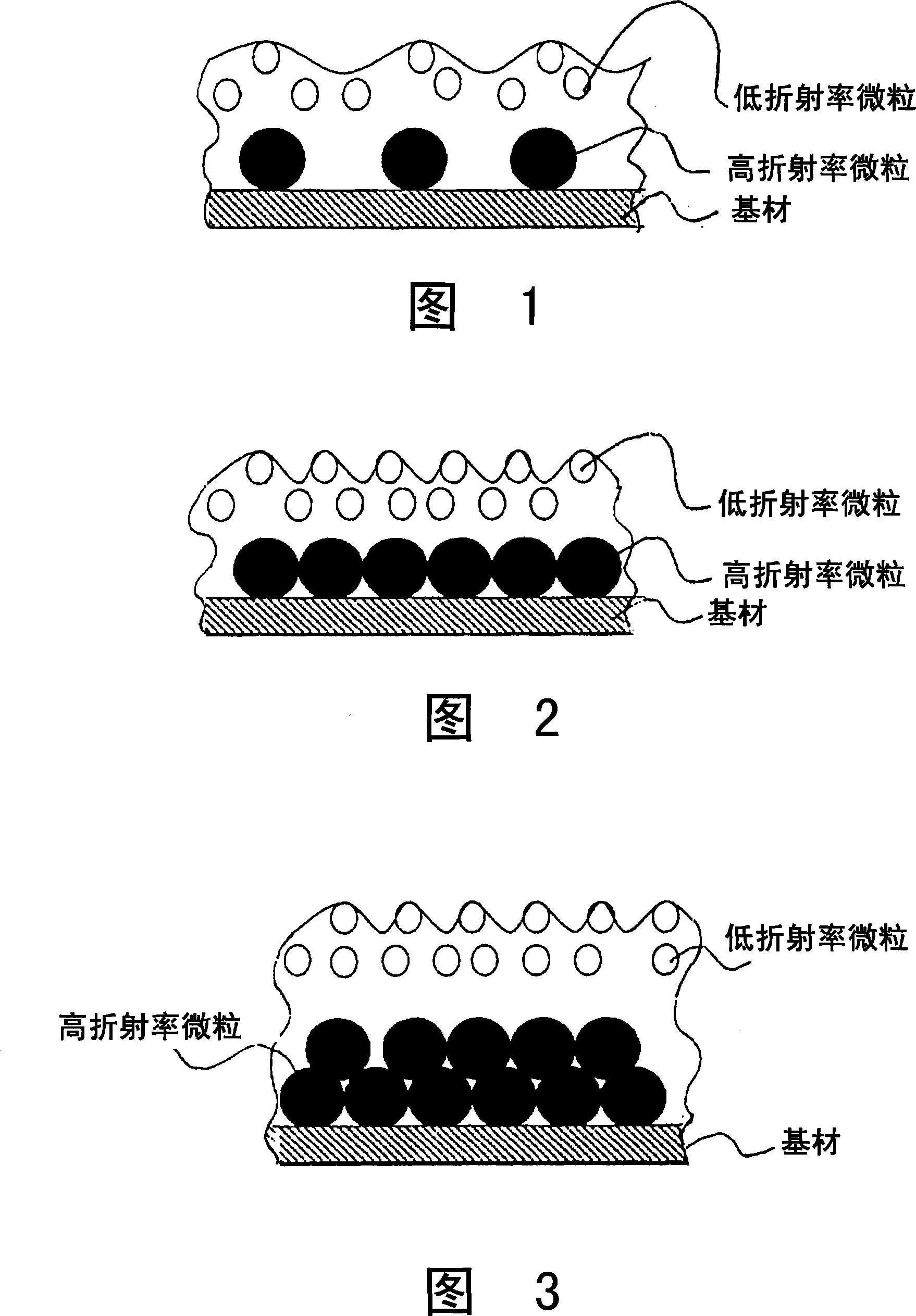

Method used

Image

Examples

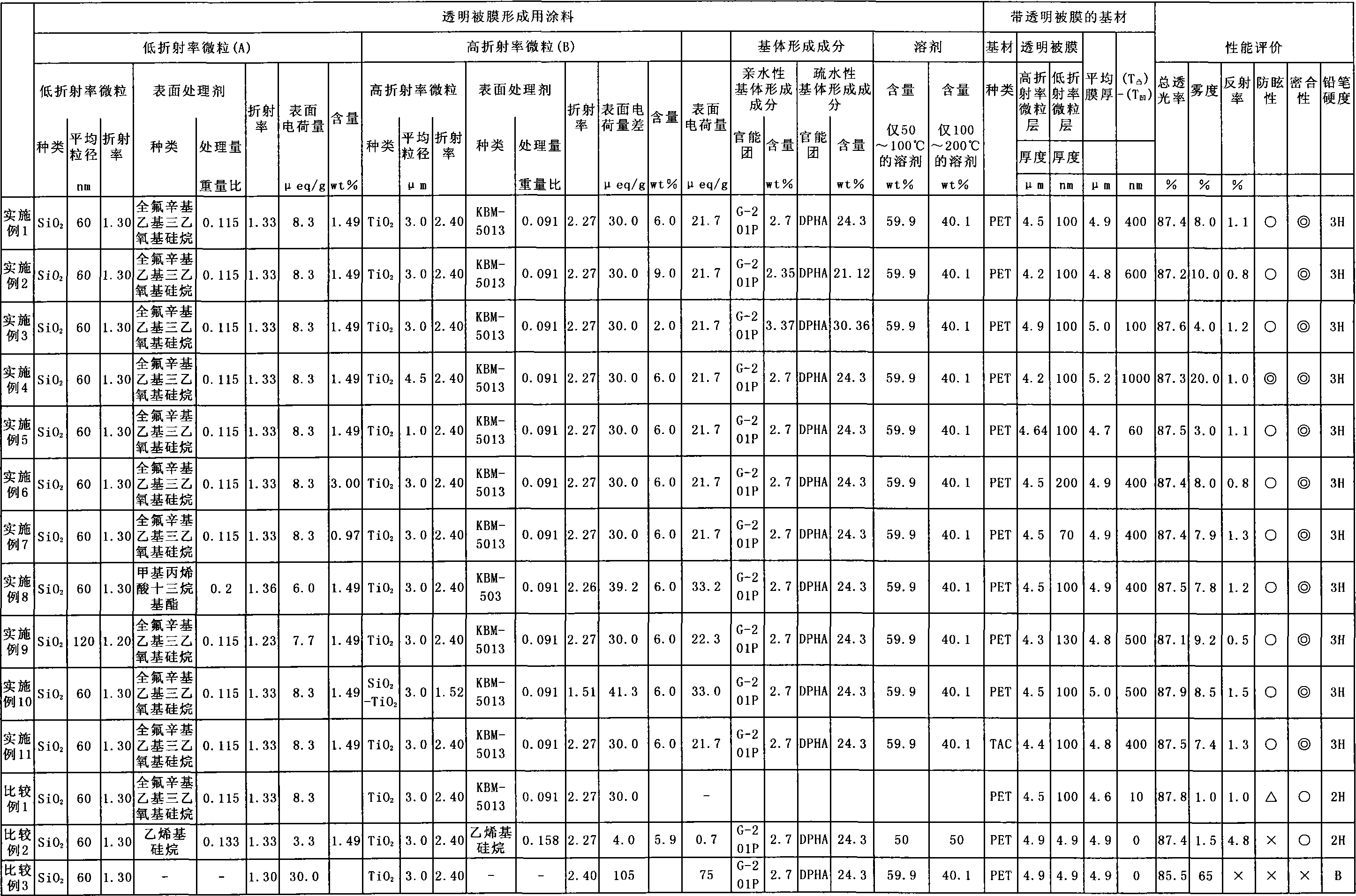

Embodiment 1

[0157] Preparation of transparent film-forming coating material (A-1)

[0158] As a low refractive index component, a silica-based hollow fine particle dispersion sol (manufactured by Catalyst Chemical Industry Co., Ltd.: Sulliar 1420, average particle diameter: 60 nm, concentration: 20.5% by weight, dispersed Medium: isopropanol, particle refractive index: 1.30). In 100 g of this sol, 10 g of perfluorooctylethyl triethoxysilane (Toray Dow Corning Co., Ltd. (Toray Dow Corning Co., Ltd.): AY43-158E, SiO 2 Component: 26.6% by weight), 10 g of ultrapure water was added, and stirred at 40° C. for 5 hours to obtain a surface-treated silica-based hollow fine particle dispersion sol (solid content: 19.3%). The surface charge of the surface-treated silica-based hollow fine particle dispersion sol was measured and found to be 8.3 μeq / g. Titanium oxide particles (manufactured by Shokubai Kasei Co., Ltd.: TITAN MICROBEAD, average particle diameter: 3 μm, particle refractive index: 2.40...

Embodiment 2

[0179] Preparation of transparent film-forming paint (A-2)

[0180] In Example 1, except that 7.7 g of the surface-treated silica-based hollow particle dispersion and 45 g of the surface-treated titanium oxide particle dispersion were used, the transparent film-forming paint (A-2) was prepared in the same manner. .

[0181] Preparation of substrate (2) with transparent film

[0182] In Example 1, except having used the coating material (A-2) for transparent film formation, it carried out similarly, and produced the base material (2) with a transparent film. The cross-section of the transparent film was observed with a transmission electron microscope, and it was confirmed that the silica-based hollow fine particles formed a layer with a thickness of about 100 nm in the upper part and titanium oxide particles existed in the lower part.

[0183] The total light transmittance, haze, and reflectance of light rays with a wavelength of 550 nm of the obtained substrate (2) with a t...

Embodiment 3

[0185] Preparation of transparent film-forming paint (A-3)

[0186] In Example 1, except that 7.7 g of the surface-treated silica-based hollow particle dispersion and 10 g of the surface-treated titanium oxide particle dispersion were used, a transparent film-forming paint (A-3) was produced in the same manner. .

[0187] Preparation of substrate (3) with transparent film

[0188] In Example 1, except having used the coating material (A-3) for transparent film formation, it carried out similarly, and produced the base material (3) with a transparent film. The cross-section of the transparent film was observed with a transmission electron microscope, and it was confirmed that the silica-based hollow fine particles formed a layer with a thickness of about 100 nm in the upper part and titanium oxide particles existed in the lower part.

[0189] The total light transmittance, haze, and reflectance of light rays with a wavelength of 550 nm of the obtained substrate (3) with a tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com