Method for preparing hydrocarbon fuel and methanol

A technology of hydrocarbon fuel and methanol, which is applied in the field of producing hydrocarbon fuel and methanol by using lignin, which can solve the problems of ineffective utilization of lignin, waste of lignin resources, environmental pollution, etc., and achieve high raw material utilization and yield High effect with broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

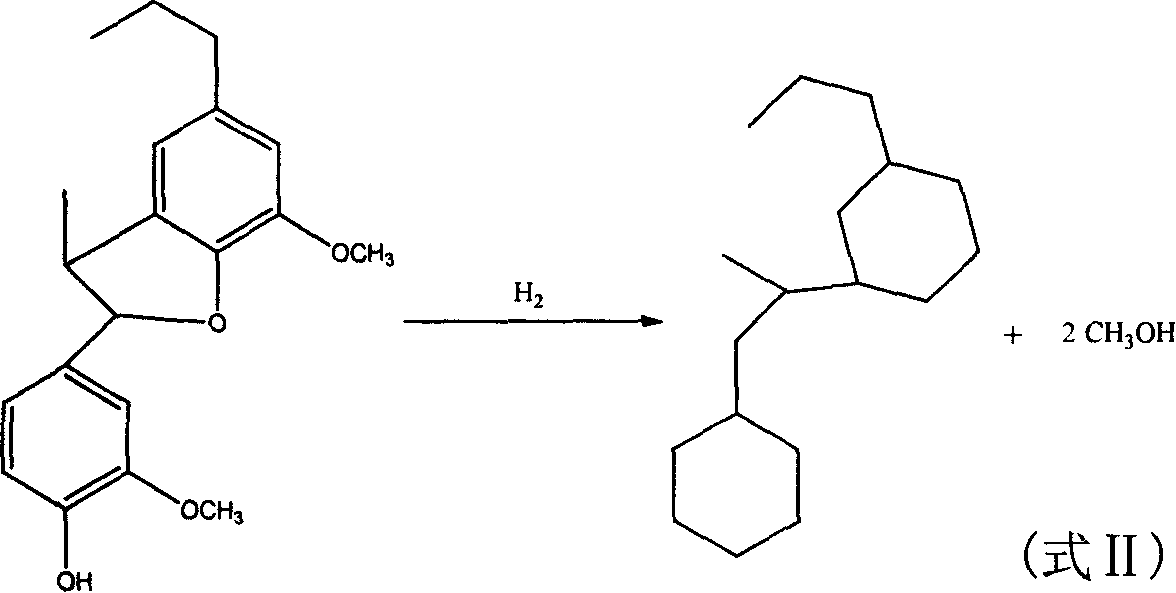

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, directly use wood flour as raw material to prepare hydrocarbon fuel and methanol

[0023] In this embodiment, the wood powder rich in lignin is directly used as raw material to prepare hydrocarbon fuel and methanol through a two-step catalytic hydrogenation reaction. - 30 mL of ethanol solution was extracted with a Soxhlet extractor for 48 hours. After drying in the air, add 75 mL of 1,4-dioxane-water solution (lignin solvent) and 0.5 g of 5% Rh / C catalyst (purchased from Baoji Botong Nonferrous Metals Co., Ltd.) mixed at a ratio of 1:1 to high pressure In the kettle (the pH value of the reaction system is about 7), then fill it with hydrogen to 40bar at room temperature, then raise the temperature to 200°C, stir at a speed of 500rpm, and react for 5 hours; after the first step of the catalytic hydrogenation reaction, filter the reaction solution , the filtrate was extracted 3 times with cyclohexane, the extracts were combined, the cyclohexane was distill...

Embodiment 2

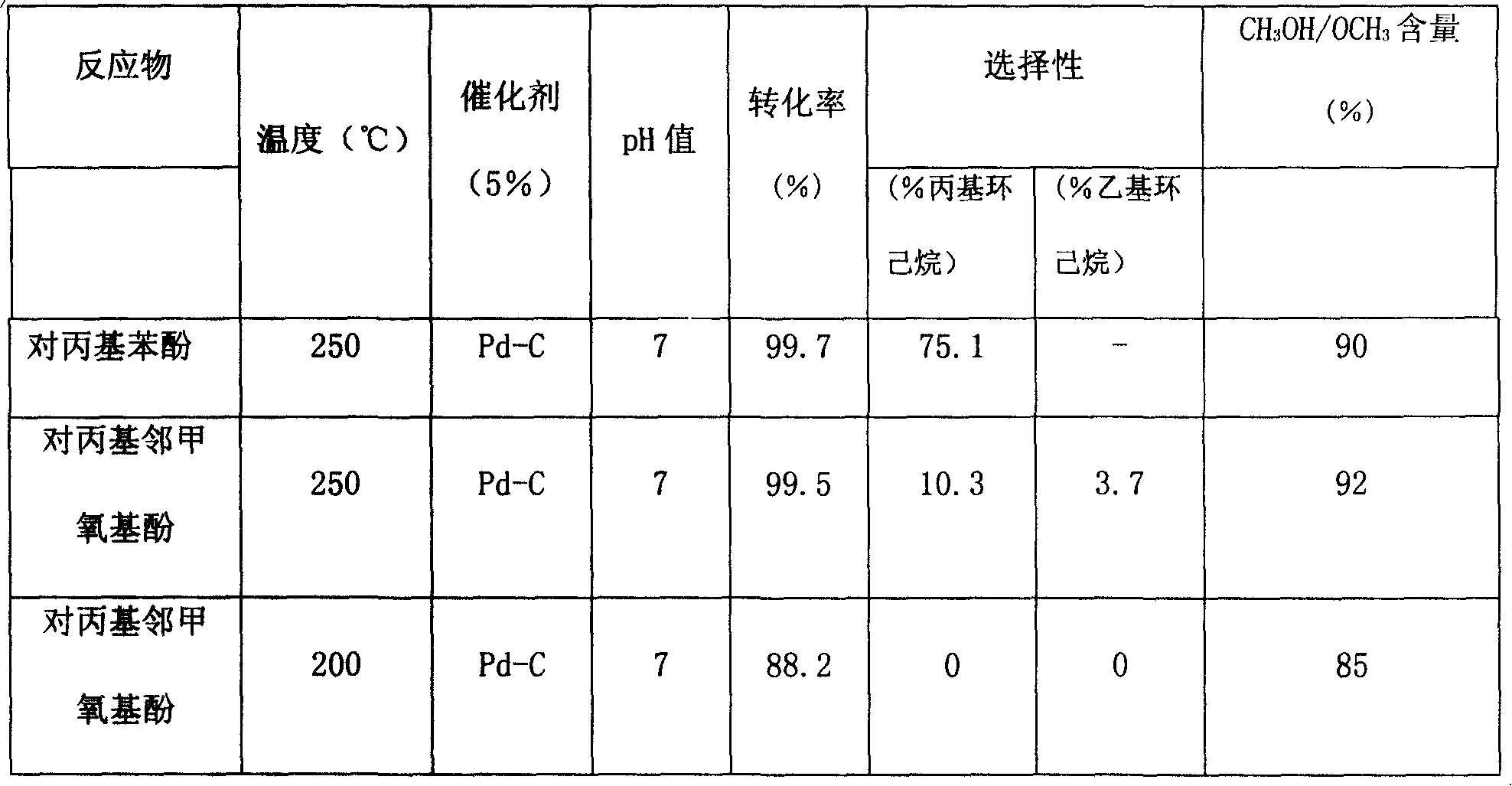

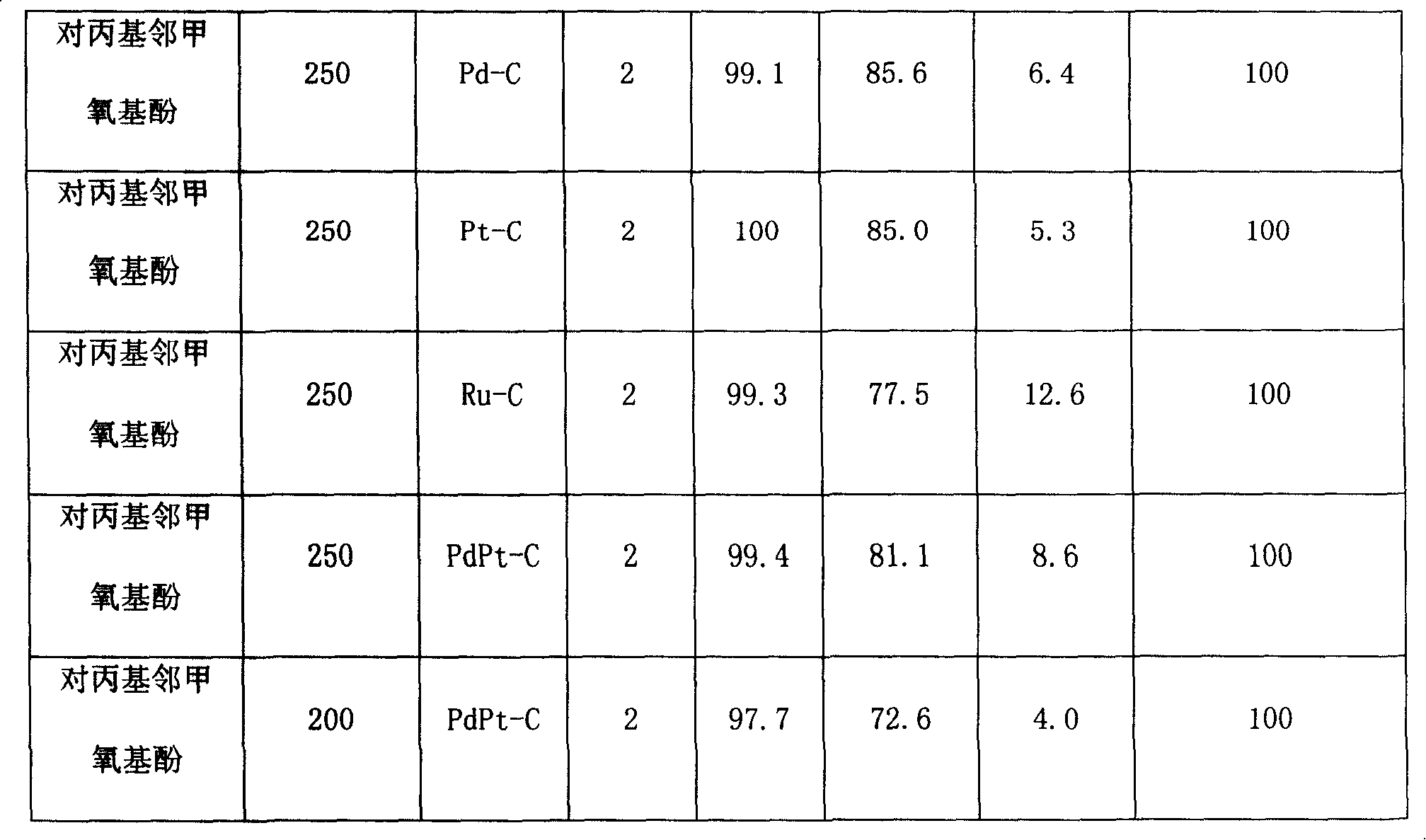

[0024] Embodiment 2, using organic lignin as raw material to prepare hydrocarbon fuel and methanol

[0025] In this example, organic lignin (purchased from Aldrich Company) was used as raw material to prepare hydrocarbon fuel and methanol through a one-step catalytic hydrogenation reaction. The specific method was: take 1g of organic lignin, add 30mL of sulfuric acid aqueous solution of pH2 and 0.1g of 5% Pd / C catalyst, filled with hydrogen to 30bar at normal temperature, raised the temperature to 250°C within 1 hour, and reacted for 2 hours. C 8 (Ethylcyclohexane), C 9 (Propylcyclohexane) and C 14 -C 18 The yield of naphthenic derivatives is about 10% of the raw material, and there is a large amount of methanol in the lower aqueous phase, and the yield accounts for more than 60% of the methoxyl content of the raw material lignin. At the same time, the gas in the autoclave after the reaction was detected by IR, and the result contained a small amount of CO 2 、CH 4 gas, a...

Embodiment 3

[0026] Example 3. Preparation of hydrocarbon fuel and methanol with lignin dimer 1-benzyloxy-2-methoxy-4-propyl-benzene as raw material

[0027] (Formula III)

[0028] Using lignin dimer 1-benzyloxy-2-methoxy-4propyl-benzene (molecular formula see formula III) as raw material, prepare hydrocarbon fuel and methanol through one-step catalytic hydrogenation reaction, the specific method is: take Add 1 gram of raw material whose molecular formula is formula III, add 30mL of 1% phosphoric acid aqueous solution and 0.1g of 5% Pd / C catalyst (purchased from Baoji Botong Nonferrous Metals Co., Ltd.), and fill with hydrogen to 80bar at room temperature for 1 hour Internally raise the temperature to 250°C and react for 0.2 hours. After the reaction is completed, the temperature is lowered, and the product is divided into two phases, and the upper oil phase product contains C 7 (Methylcyclohexane), C 9 (Propylcyclohexane) Hydrocarbons, C 7 Yield reaches 75% of raw material, C 9 The yi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com