Method for preparing lead telluride nano-wire

A lead telluride nanometer and nanowire technology is applied in the field of semiconductor thermoelectric nanomaterial preparation, which can solve the problems of low yield, inability to be suitable for industrial production, nanowire damage, affecting the thermoelectric performance of materials, etc., and achieves low cost, uniform size, and synthesis. low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1. Raw materials: analytically pure Pb(NO 3 ) 2 , Na 2 TeO 3 .

[0020] 2. Add 0.1808 g of Na 2 TeO 3 Put 0.3 g of PVP (K30, MW=40000) in a 50 ml autoclave, add 25 ml of double distilled water and stir to make it clear.

[0021] 3. Add 1.5 ml of hydrazine hydrate and 3 ml of ammonia water dropwise to the above solution, and continue stirring to make it clear.

[0022] 4. Add 10.5ml of twice-distilled water, seal the autoclave and place it in an oven at 180°C for 24 hours, then take it out and allow it to cool naturally to room temperature.

[0023] 5. In the above reaction solution, add 0.268 grams of Pb (NO 3 ) 2 , stirred at 5°C for 12 hours and then placed in an oven at 100°C for 12 hours. Acetone was added to the reacted system to deposit a black suspension, washed repeatedly with twice distilled water and ethanol, and dried at 80° C. for 12 hours to obtain the target product.

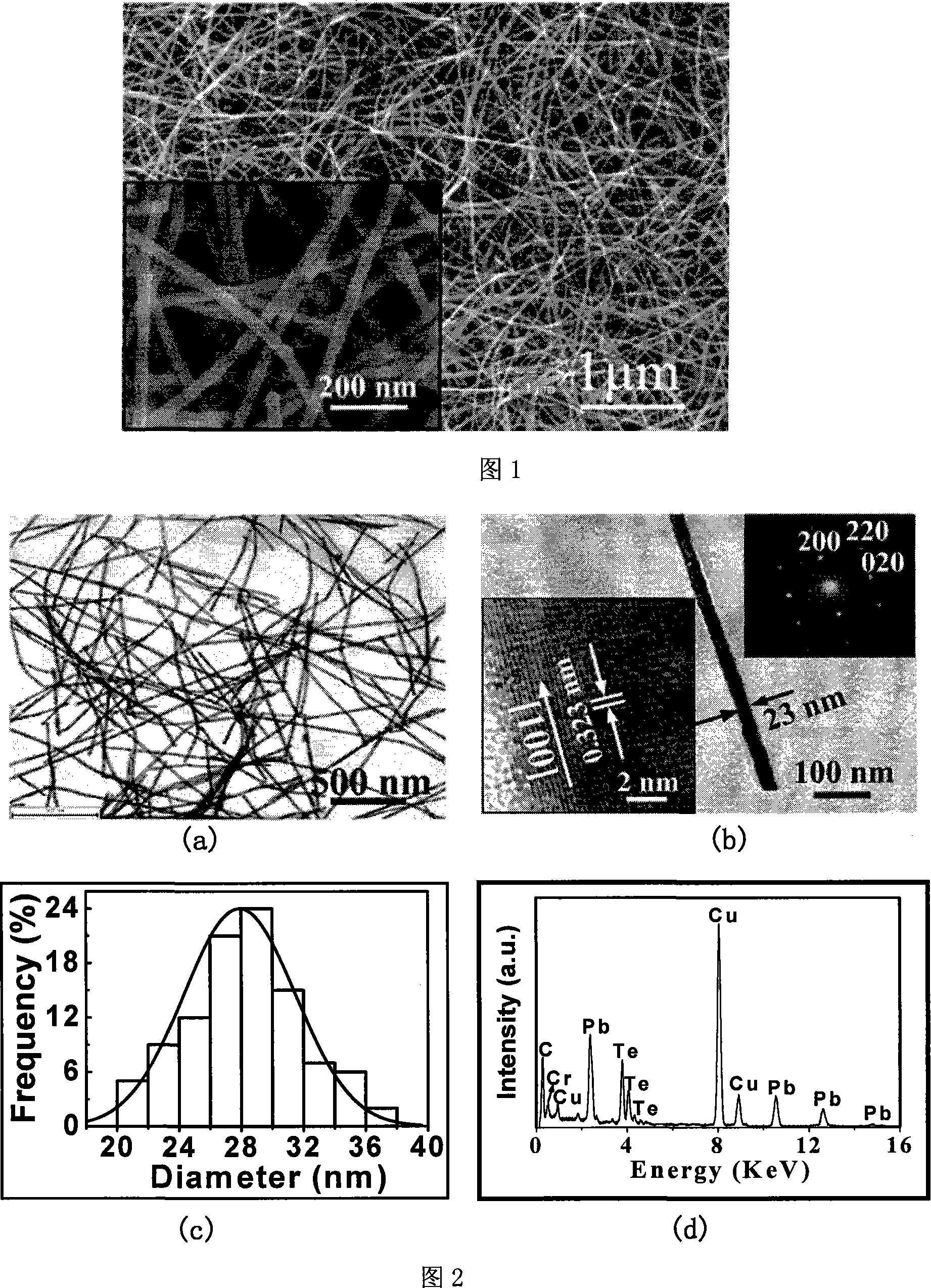

[0024] The FESEM photo of the prepared PbTe nanowires is shown in Figure 1. Fr...

Embodiment 2

[0026] 1. Raw materials: analytically pure Pb(NO 3 ) 2 , Na 2 TeO 3 .

[0027] 2. Add 0.3616 g of Na 2 TeO 3 Put 0.6 g of PVP (K30, MW=40000) in a 100 ml autoclave, add 50 ml of double distilled water and stir to make it clear.

[0028] 3. Add 3 ml of hydrazine hydrate and 6 ml of ammonia water dropwise to the above solution, and continue to stir to make it clear.

[0029] 4. Add 21ml of double-distilled water, seal the autoclave and place it in an oven at 180°C for 24 hours, then take it out and let it cool down to room temperature naturally.

[0030] 5. In the above reaction solution, add 0.536 grams of Pb (NO 3 ) 2 , stirred at 5°C for 12 hours and then placed in an oven at 100°C for 12 hours. Acetone was added to the reacted system to deposit a black suspension, washed repeatedly with double distilled water and ethanol, and dried at 60°C for 12 hours to obtain the target product.

[0031] The obtained result is close to the obtained result of Example 1.

Embodiment 3

[0033] 1. Raw materials: analytically pure Pb(NO 3 ) 2 , Na 2 TeO 3 .

[0034] 2. Add 0.1085 g of Na 2 TeO 3 Put 0.18 g of PVP (K30, MW=40000) in a 30 ml autoclave, add 15 ml of double distilled water and stir to make it clear.

[0035] 3. Add 0.9 ml of hydrazine hydrate and 1.8 ml of ammonia water dropwise to the above solution, and continue stirring to make it clear.

[0036] 4. Add 6.3ml of twice distilled water, seal the autoclave and place it in an oven at 180°C for 24 hours, then take it out and let it cool down to room temperature naturally.

[0037] 5. In the above reaction solution, add 0.161 grams of Pb (NO 3 ) 2 , stirred at 5°C for 12 hours and then placed in an oven at 100°C for 12 hours. Acetone was added to the reacted system to deposit a black suspension, washed repeatedly with double distilled water and ethanol, and dried at 60°C for 12 hours to obtain the target product.

[0038]The obtained result is close to the obtained result of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com