Freeze bag for storing liquid nitrogen refrigeration material

A liquid nitrogen freezing and cryopreservation technology, which is applied in bag making operations, gas/liquid distribution and storage, paper/cardboard containers, etc., can solve problems such as unsafe hidden dangers, damage, and easy-to-expand bags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: (preparation of polyamide fiber cryopreservation bag)

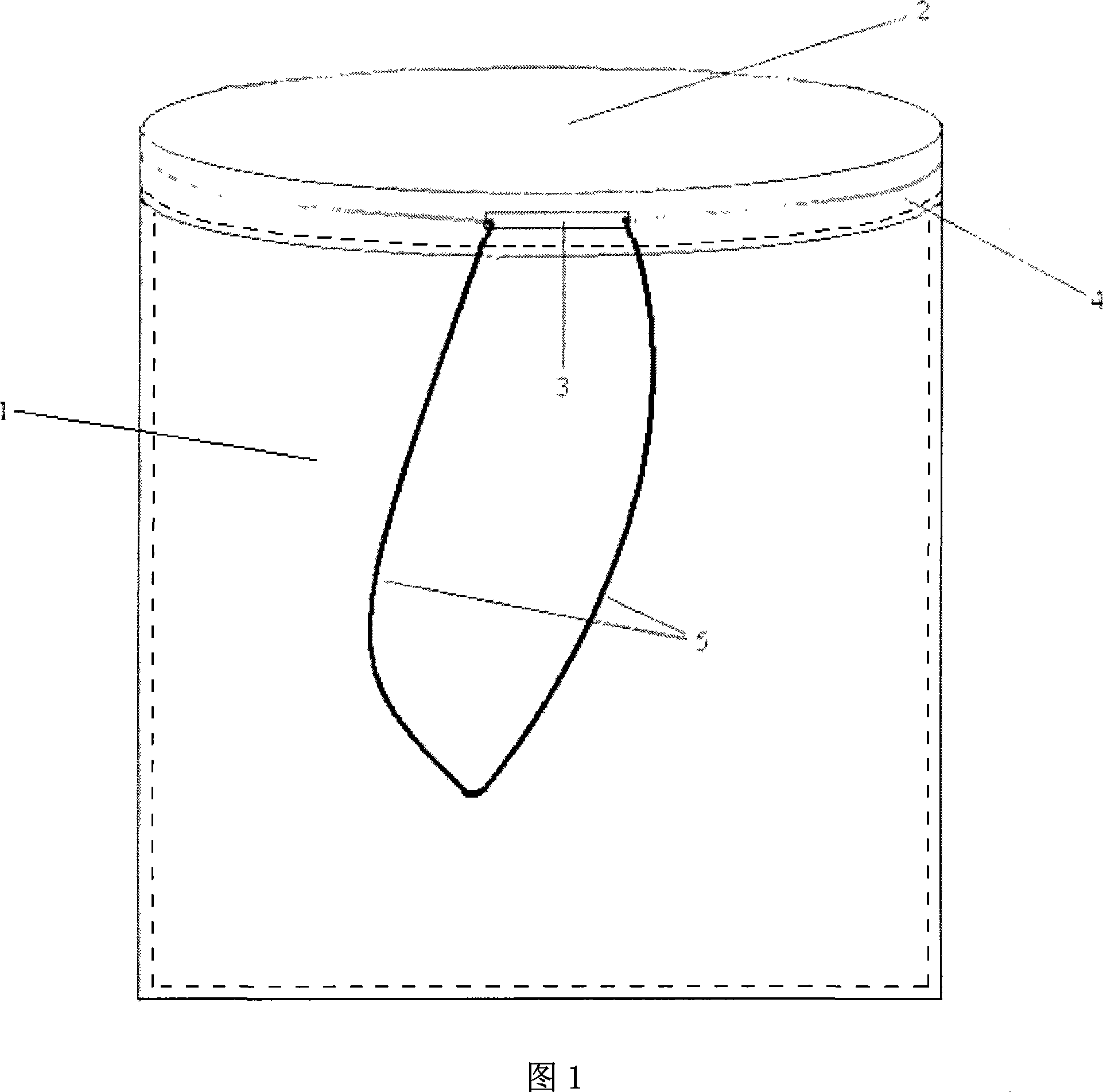

[0025] A cryopreservation bag for storing liquid nitrogen freezing materials, the bag includes a bag body 1 with both sides and the lower end sealed and a bag mouth 2 with an open upper end, wherein the bag body 1 is ultra-low temperature resistant to -196°C and 120°C The 100-500 mesh nylon single (long) silk screen silk (net) of ℃ high temperature is material, and its two sides and the lower end are sewn and sealed; A keyhole opening 3 with a width of 1.5 cm and a width of 0.5 cm; the pocket opening 2 is turned outwards and downwards from the upper edge of the bag body 1, and is sewn together with the bag body 1 to form an annular tunnel with a keyhole opening 3 and an open upper end Formed after 4; Wherein, the keyhole opening 3 is positioned at the central axis of the outer side of the annular channel 4 of the bag body; a drawable rope 5 consistent with the material of the bag body 1 is set in the ...

Embodiment 2

[0034] Embodiment 2: (preparation of polyester freezer bag)

[0035] In this example, 100-400 mesh polyester single (long) silk screen silk (net) is used as the material; on either side of the bag body 0.8 cm from the top edge, a keyhole with a length of 2 cm and a width of 0.5 cm is processed with a keyhole machine Open the mouth; turn the upper edge of the bag body outward and down by 2.0 cm; choose polyester with a diameter of 0.4 cm and a length of 200 cm as the rope; use 1.0% SODOSIL for the semi-finished product of the frozen storage bag The RAM 05 cleaning agent aqueous solution was ultrasonically soaked for 8 minutes and washed with water for 3 times; the rest of the process and steps were the same as in Example 1.

Embodiment 3

[0036] Embodiment 3: (the liquid nitrogen freezing of fresh Chinese cabbage blade)

[0037] Frozen material: choose intact fresh Chinese cabbage leaves;

[0038] Detection index: glucosinolate composition and content;

[0039] The purpose of freezing: to avoid the degradation of glucosinolates caused by tissue loss and damage;

[0040] Freeze storage bag: select the 200-mesh nylon freeze storage bag or polyester freeze storage bag of embodiment 1 or 2 for use;

[0041] Freezing steps and specific usage of freezer bags:

[0042] (1) Choose 32×23cm 2 freezer bags;

[0043] (2) Prepare labels (with lanyard), aluminum foil, liquid nitrogen (tank), freezing gloves, goggles, polyethylene foam board, a 500-mesh nylon freezing bag, insulation tank (less freezing material) or high-density Polyethylene foam insulation box (more frozen materials);

[0044] (3) Chinese cabbage leaves are wrapped with aluminum foil;

[0045] (4) After putting into the frozen storage bag, tie a label...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com