Method for testing operating parameter of stirring kettle

A technology of operating parameters and detection methods, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze fluids, etc., can solve the problems of low accuracy, cumbersome process, easy blockage, etc., and achieves low requirements for measurement conditions, simple and convenient installation, and small measurement error. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Solid-liquid mixed system, laboratory cold mold experiment, measurement of critical stirring speed.

[0042] The inner diameter of the stirred tank is 110mm, the material is plexiglass, the experimental medium is water and glass beads, and the density of water is 1.0×10 3 kg·m -3 , the density of glass beads is 2.9×10 3 kg·m -3 , The particle diameter is 0.7mm. The stirring paddle is a paddle-type impeller with a diameter of 65 mm and 600 ml of water. The test speed is 3.33~10.83r·s -1 , the apparent concentration of the slurry is 0.008~0.032g·ml -1 , the acoustic emission signal sampling frequency is 100KHz.

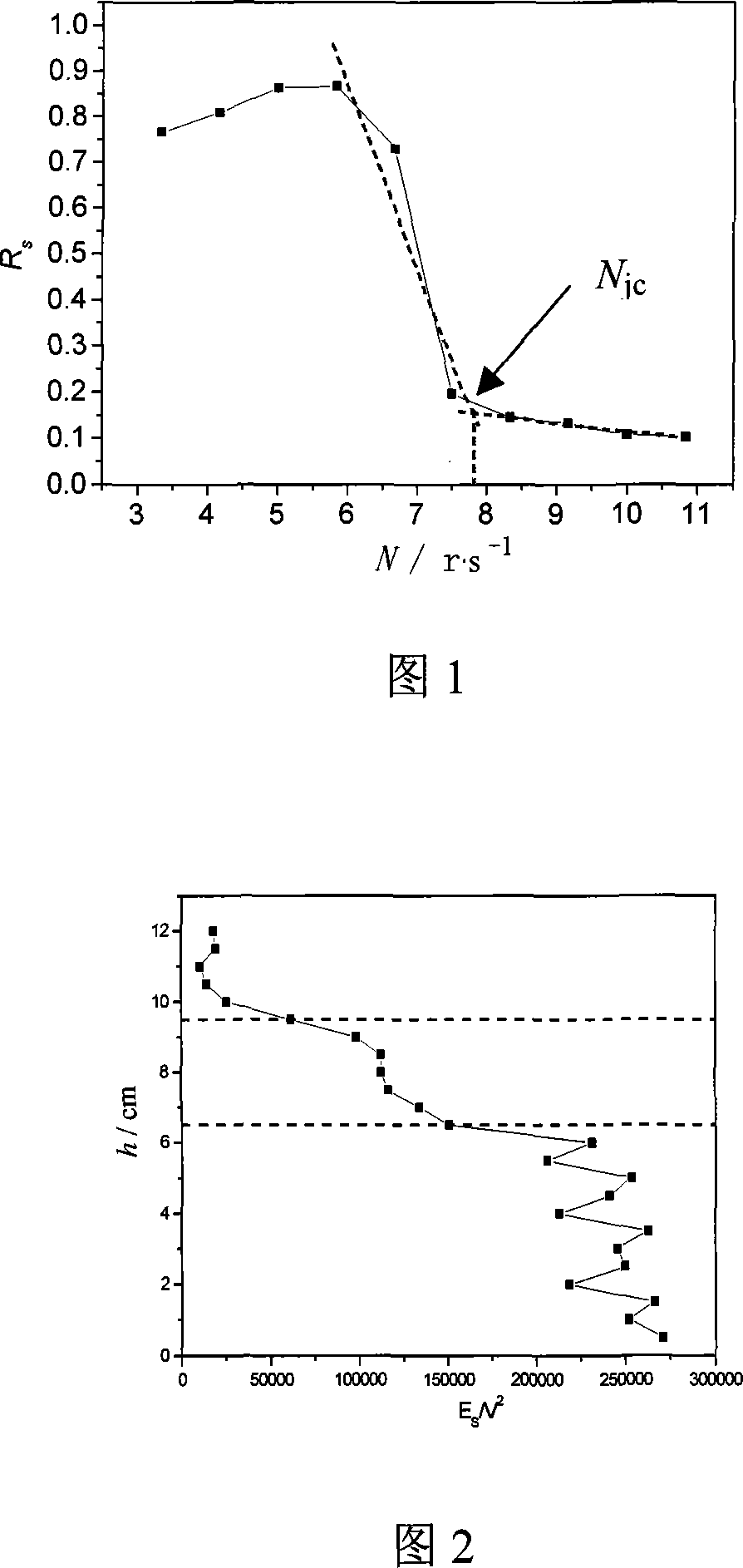

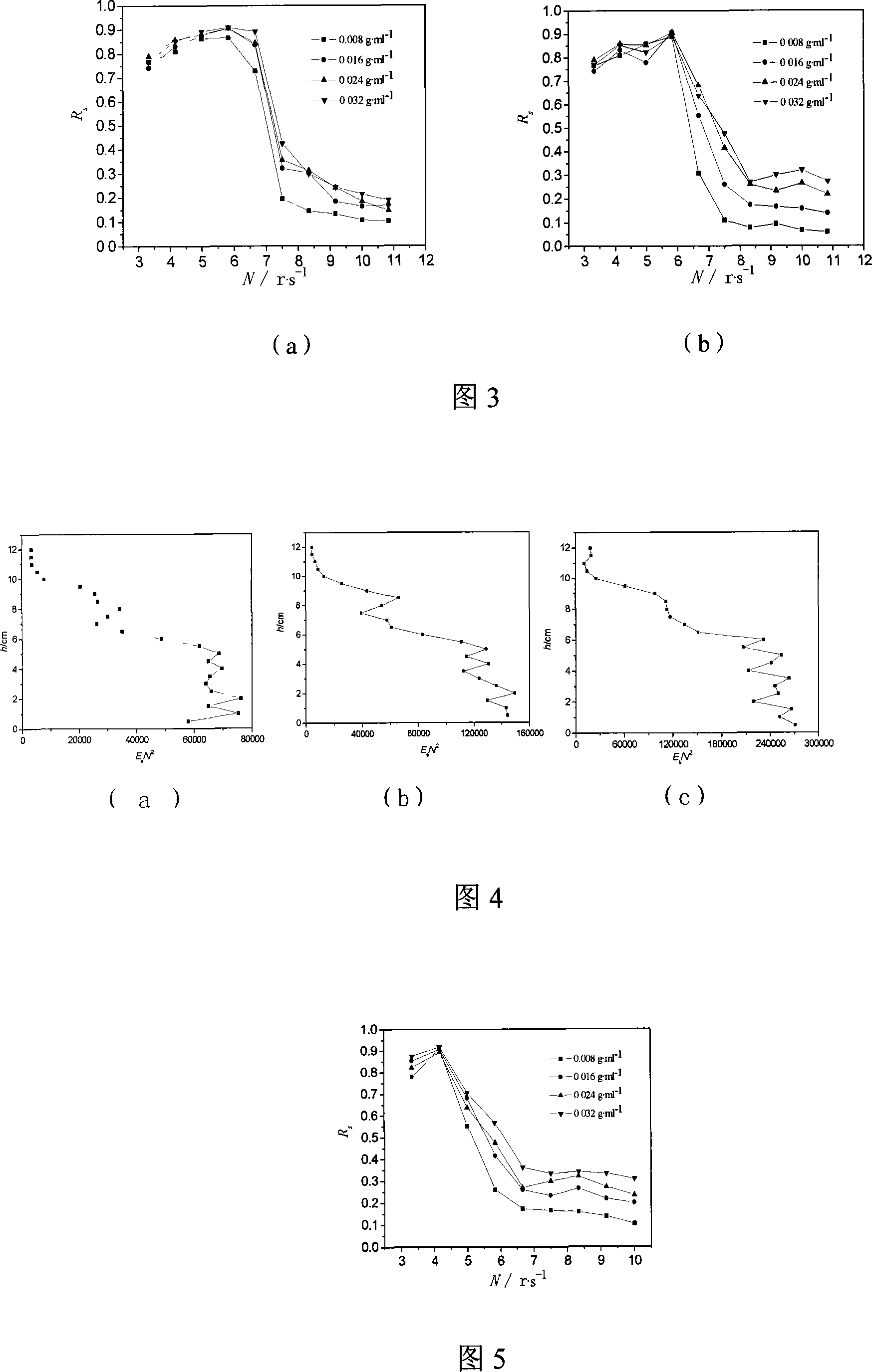

[0043] The collected acoustic emission signal is decomposed by second-order Daubechies 9 scale wavelet and R / S fractal technology is used to select the acoustic emission signal in the characteristic frequency band with Hurst value less than 0.5 as the acoustic signal energy fraction R representing the movement of solid particles s . Investigate R s The v...

Embodiment 2

[0048] For the solid-liquid mixed system, the same laboratory cold model test as in Example 1 was carried out to measure the suspension height and liquid level of the slurry.

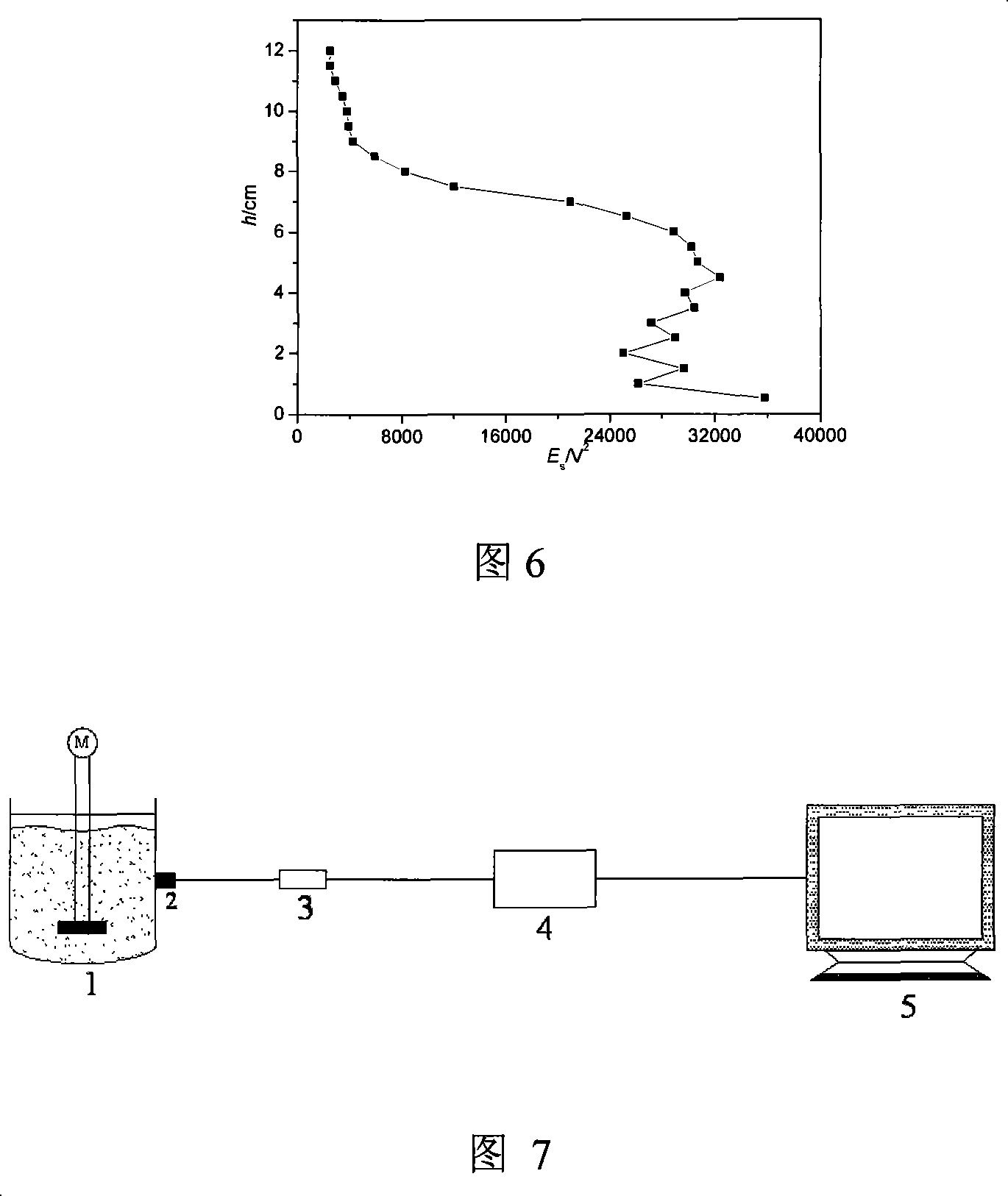

[0049] The acoustic emission receiving device is placed on the side wall of the stirred tank, and the test speed is 8.33r s -1 . Serum concentration is 0.016g·ml -1 , the particle diameter is 0.7mm, and the sampling frequency is 1000KHz.

[0050] The collected acoustic emission signal is decomposed by the second-order Daubechies 9 scale wavelet and the R / S fractal technology is used to obtain the energy value E of the acoustic signal representing the movement of solid particles s , examine E s The change law with the axial direction of the stirred tank is shown in Figure 4.

[0051] According to the criterion, the height corresponding to the boundary position between the first and second areas is the slurry suspension height, and the height corresponding to the boundary position between the second a...

Embodiment 3

[0055] Gas-liquid-solid mixed system, slurry polyethylene pilot plant, measuring the critical stirring speed, the acoustic emission receiving device is placed at the static liquid level of 2 / 5 of the side wall of the stirred tank.

[0056] The volume of the test kettle is 10L, the material is stainless steel, the main raw material is high-purity ethylene, a small proportion of propylene or 1-butene is used as a comonomer, hydrogen is used as a molecular weight regulator, hexane is used as a solvent, and tetrachloromethane is used. Titanium oxide / magnesium ethoxide supported high-efficiency Z-N catalyst reacts at a temperature of 87°C and a pressure of 0.8MPa to produce polyethylene. A gas-liquid-solid three-phase system consisting of ethylene gas, n-hexane solvent and polyethylene solid is formed in the reactor. The stirring impeller is a disc-type turbine impeller with a diameter of 30cm and a sampling frequency of 100KHz.

[0057] The energy fraction R of the acoustic signa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com