Customizing electroconductive film of dye sensitization TiO2 nanocrystalline solar battery and preparation thereof

A technology of solar cells and conductive films, which is applied in photosensitive equipment, electrolytic capacitors, circuits, etc., can solve the problems of low conversion efficiency of solar cells, high cost and restricted promotion, so as to improve conversion efficiency, break through photoelectric conversion efficiency, and increase the number of photons The effect of scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

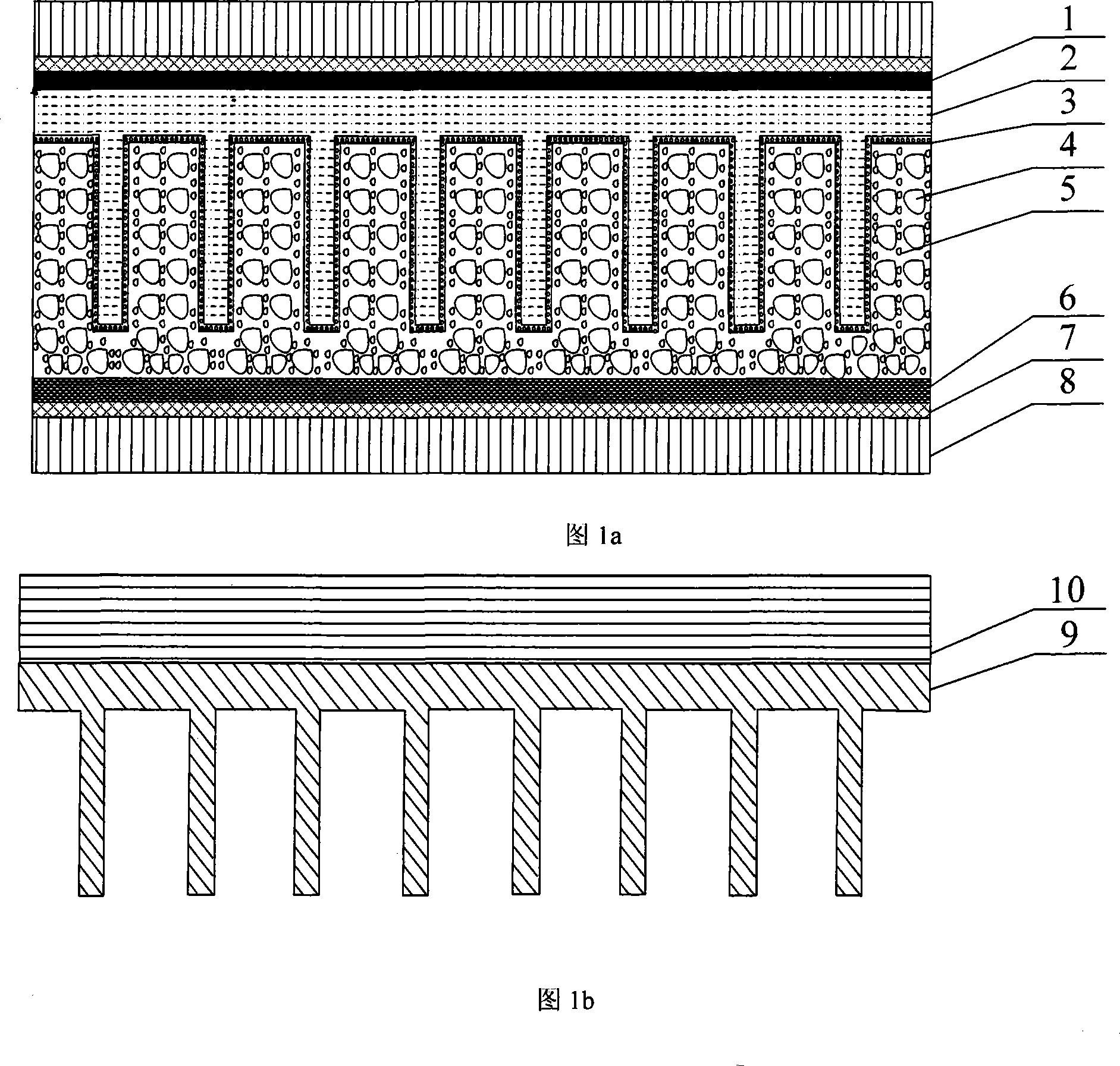

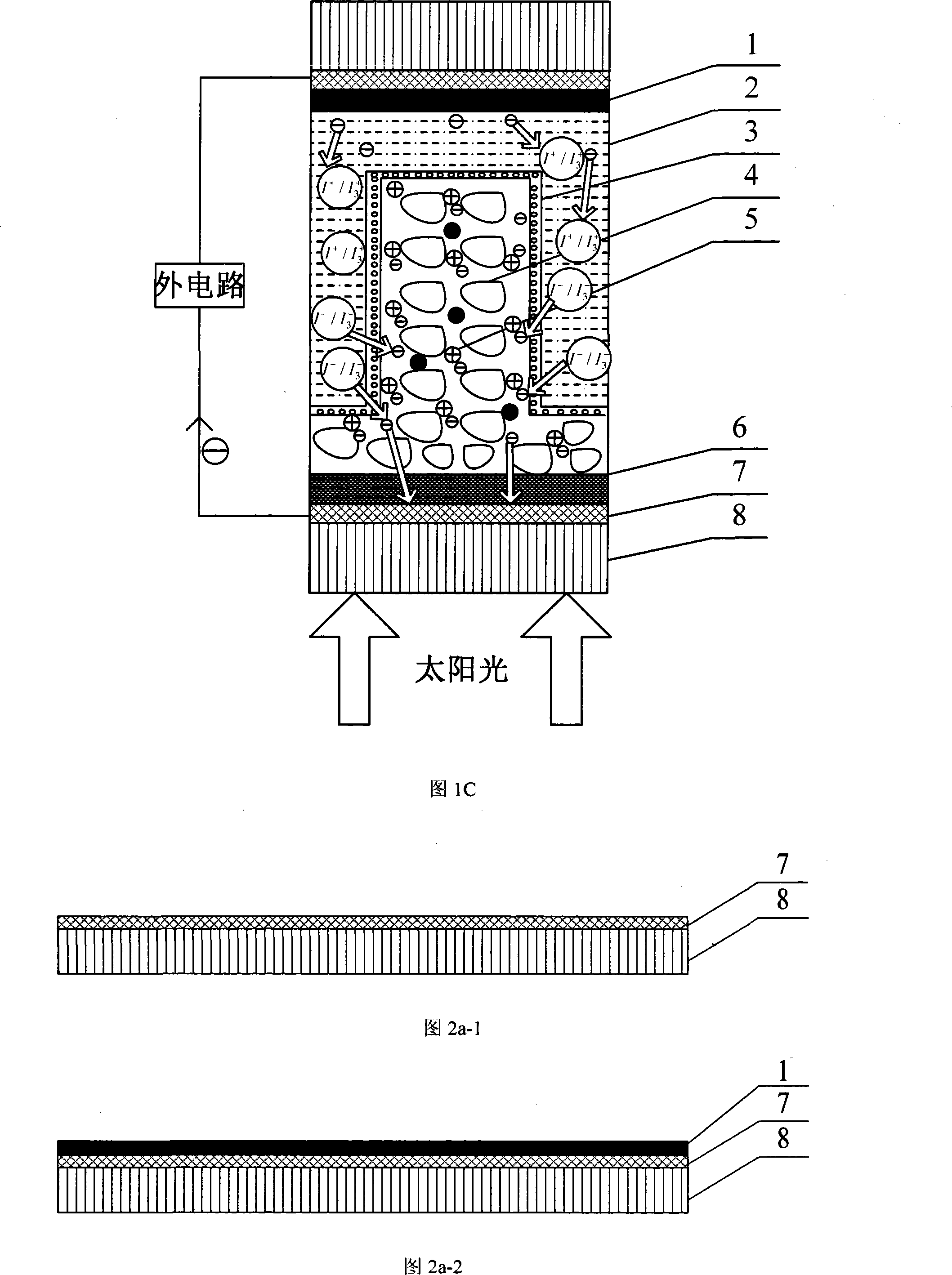

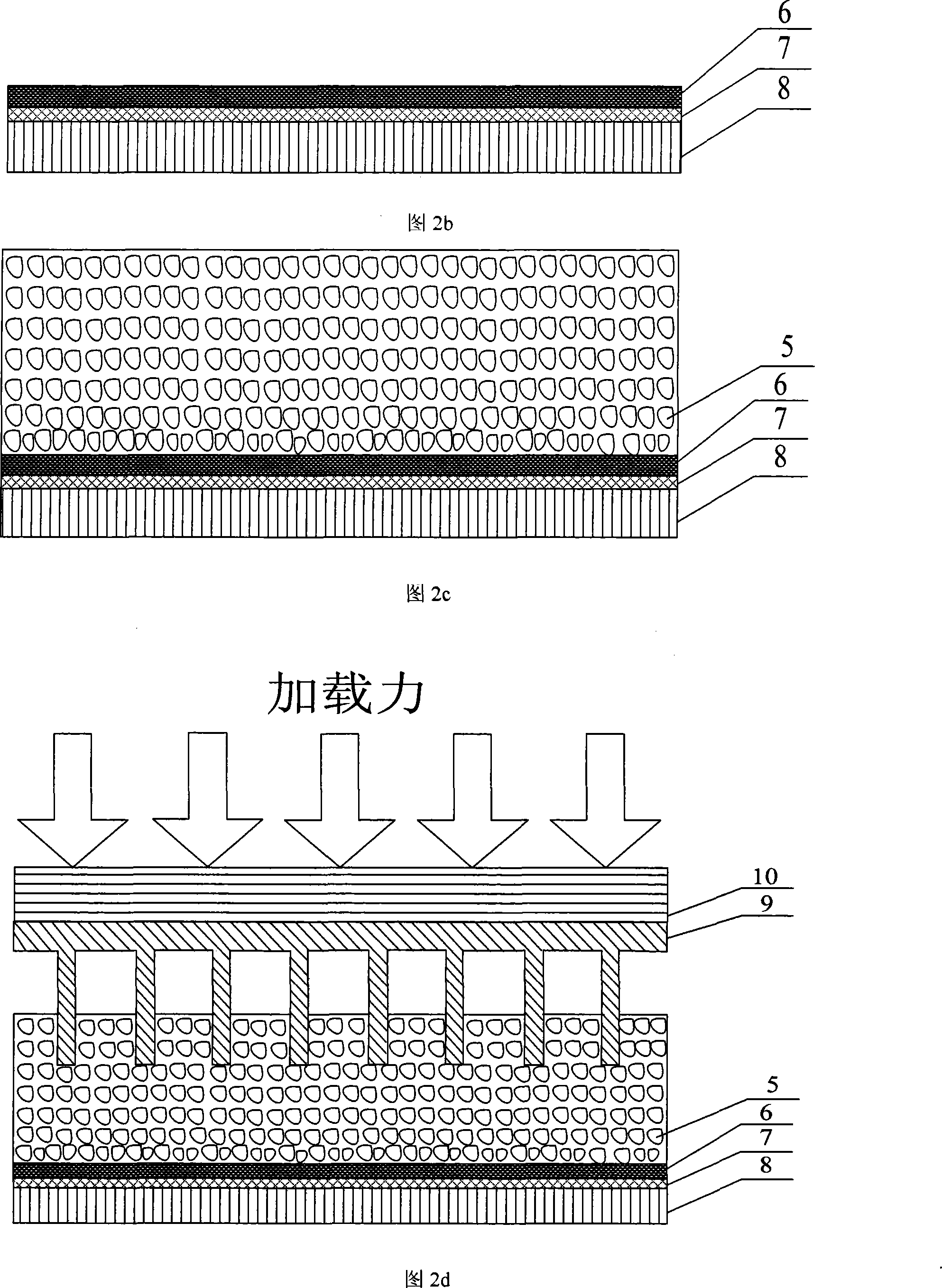

[0026] TiO with customized microstructure described in the present invention 2 Dye-sensitized solar cells with conductive thin films with customized microstructures, as shown in Figure 1a. The overall structure of this dye-sensitized solar cell is that the transparent conductive glass substrate is used as the positive electrode, and dense TiO 2 Blocking layer, TiO with customized microstructure 2 Conductive film, surface modified TiO 2 layer, adsorption of dye molecules, electrolyte, metal negative electrode. The contact surface between the customized microstructure conductive film and the electrolyte is rectangular, the depth of the rectangle is nanoscale (200nm), and the three-dimensional shape is an indented cuboid, thus forming a nanoscale microstructure conductive film.

[0027] Customized microstructure TiO according to the present invention 2 The geometric characteristics of the conductive film are (see Figure 2f): TiO 2 The cross-sectional shape of the conductive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com