Method for producing potassium chloride by steel enterprise sintering electro-precipitating dust

A potassium chloride and electrostatic precipitator technology, applied in the direction of alkali metal chloride, etc., can solve the problems of high energy consumption, poor quality of sintered ore, and low production capacity, and achieve low energy consumption, convenient operation, and simple and easy process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

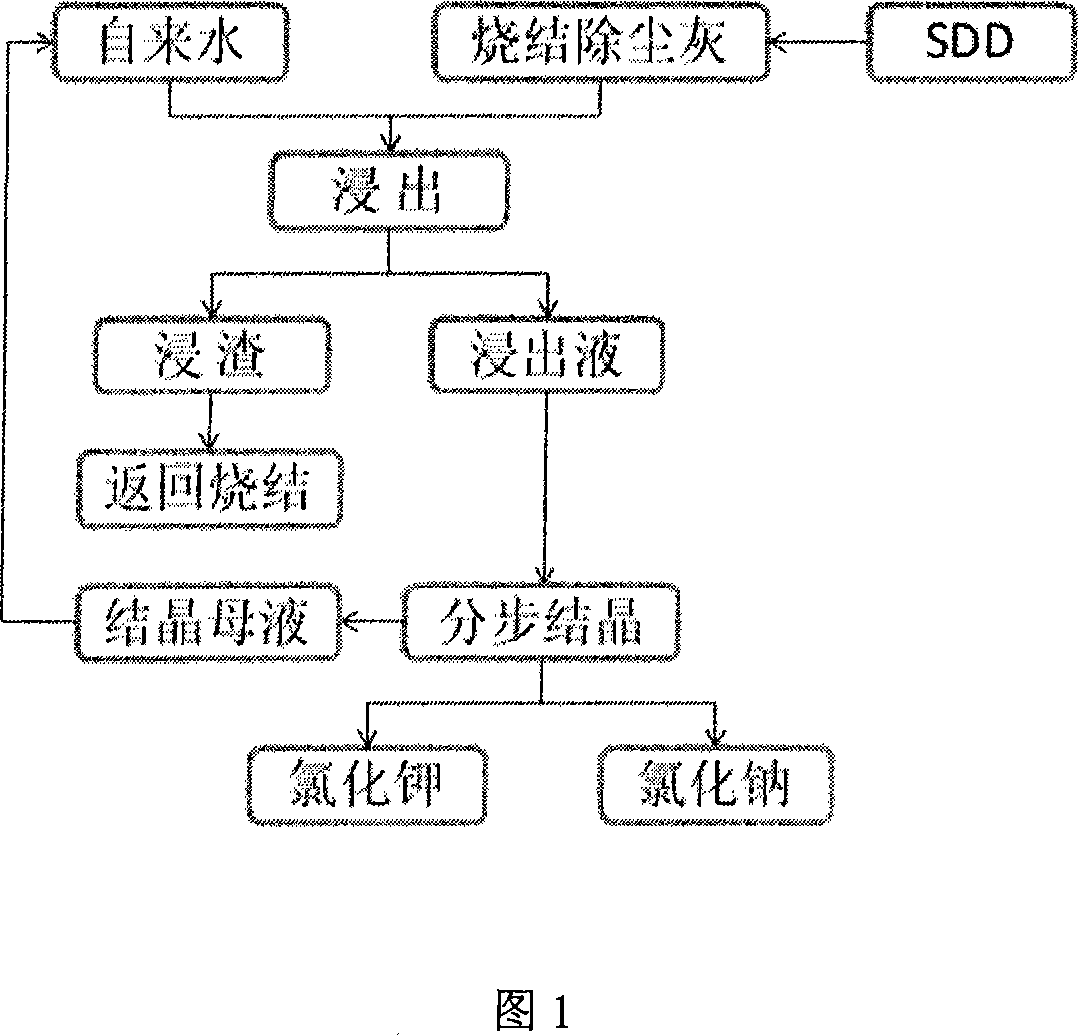

[0020] At room temperature, use a liquid-solid ratio of 1.2 / 1, leaching at a constant speed for half an hour. After solid-liquid separation, the leaching solution is used as the leaching agent for the second leaching, and 0.8% SDD is added at the same time to inhibit the leaching of impurities such as copper, lead, calcium, and magnesium. After filtering, return the filter residue to the sintering process. After the filtrate was evaporated to 1 / 4 volume, it was slowly cooled and crystallized step by step to obtain the potassium chloride product. After analysis, the potassium chloride had a purity of 95.7%, a calcium content of 1.5%, a magnesium content of 0.3%, and a sodium content of 0.6%. The mother liquor is returned and combined with tap water as the initial leachate.

Embodiment 2

[0022] At room temperature, use a liquid-solid ratio of 1 / 1, leaching at a constant speed for half an hour, after solid-liquid separation, the leaching solution is used as the leaching agent for the second leaching, and 1% SDD is added at the same time to inhibit the leaching of impurities such as copper, lead, calcium, and magnesium After filtering, return the filter residue to the sintering process. After the filtrate was evaporated to 1 / 5 volume, it was cooled slowly and crystallized step by step to obtain potassium chloride and sodium chloride products. After analysis, the purity of potassium chloride was 96.6%, the calcium content was 1.5%, the magnesium content was 0.8%, and the sodium content was 1.3% %. The mother liquor is returned and combined with tap water as the initial leachate.

Embodiment 3

[0024] At room temperature, use a liquid-solid ratio of 1.5 / 1, and oscillate at a constant speed for half an hour. After solid-liquid separation, the leaching solution is used as the leaching agent for the second leaching, and 1% SDD is added at the same time to inhibit the leaching of impurities such as copper, lead, calcium, and magnesium. After filtering, return the filter residue to the sintering process. After 1 / 4 volume of the filtrate was evaporated, it was cooled slowly and crystallized step by step to obtain potassium chloride and sodium chloride products. After analysis, the purity of potassium chloride was 96.7%, the content of calcium was 0.96%, and the content of magnesium was 0.55%. The mother liquor is returned and combined with tap water as the initial leachate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com