Pressure type foamless film type oxygenating system and method thereof

A pressure type, bubble film technology, applied in the field of environmental engineering, can solve the problems of large aeration volume, high energy consumption, low oxygen utilization rate, etc., and achieve the effect of simple process, low energy consumption, and improved sludge load capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

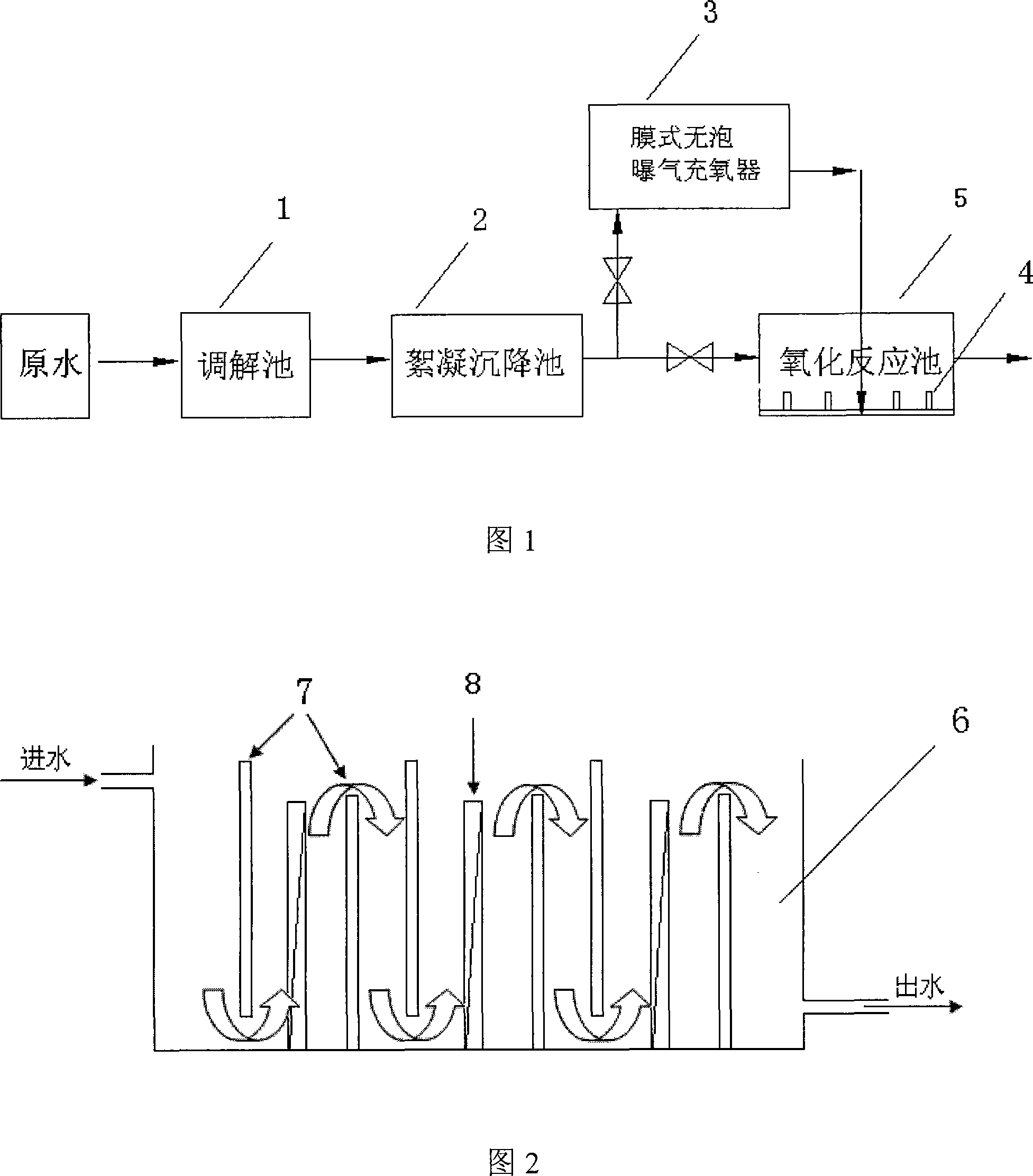

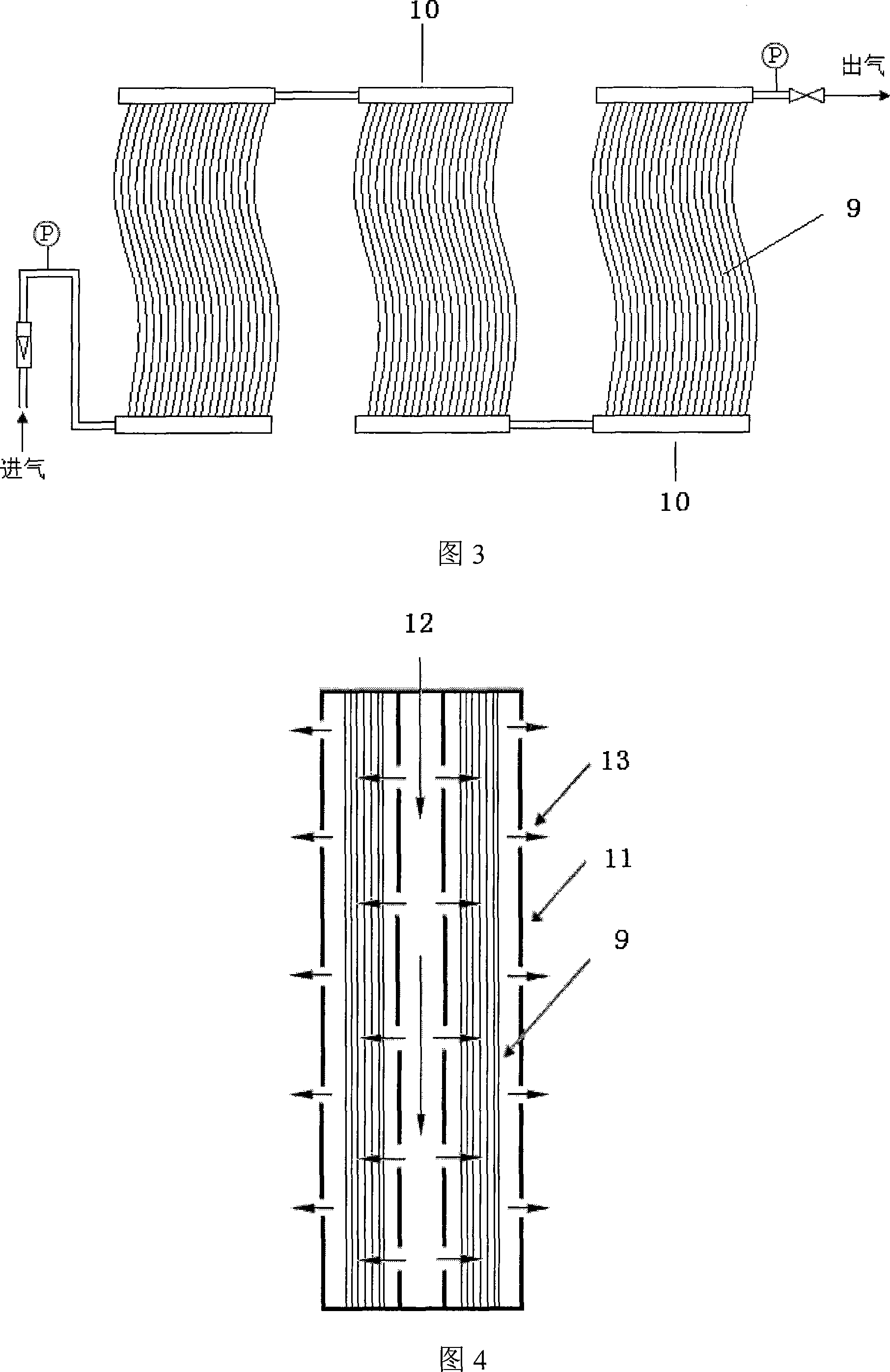

[0039] The membrane device used is PP hollow fiber curtain membrane, the process is shown in Figure 2, and there are 3 membrane devices; the size of the membrane type non-bubble oxygenator is 30×21×30cm 3 , PP hollow fiber membrane pore size: 0.1-0.2μm, membrane wall thickness: 40-50μm, outer diameter: 450μm, porosity: 40-50%, air permeability: >7.0×10 -2 (cm 3 / cm 2 ·s·cmHg), the bubble point is MPa. The device size is 20×25cm, the effective length of the membrane filament is 20cm, and the effective area of the membrane is 1×3m 2 . The test water is pure water, and the dissolved oxygen is considered to be close to zero at this time. The test gas is oxygen or air, and the pressure is controlled by the pressure reducing valve after passing through the gas storage tank. The hydraulic retention time in the membrane-type non-bubble oxygenator is 15min and 30min respectively, and the dissolved oxygen in the effluent is measured with a dissolved oxygen meter. The oxygenation ...

Embodiment 2

[0042] The membrane device used is PE hollow fiber curtain membrane, the process is shown in Figure 2, and there are 3 membrane devices; the size of the membrane type non-bubble oxygenator is 30×21×30cm 3 , PP hollow fiber membrane pore size: 0.1-0.2μm, membrane wall thickness: 40-50μm, outer diameter: 450μm, porosity: 40-50%, air permeability: >7.0×10 -2 (cm 3 / cm 2 ·s·cmHg), the bubble point is MPa. The device size is 20×25cm, the effective length of the membrane filament is 20cm, and the effective area of the membrane is 1×3m 2 . The test water is pure water, and the dissolved oxygen is considered to be close to zero at this time. The test gas is oxygen or air, and the pressure is controlled by the pressure reducing valve after passing through the gas storage tank. The hydraulic retention time in the membrane-type non-bubble oxygenator is 15min and 30min respectively, and the dissolved oxygen in the effluent is measured with a dissolved oxygen meter. The oxygenation ...

Embodiment 3

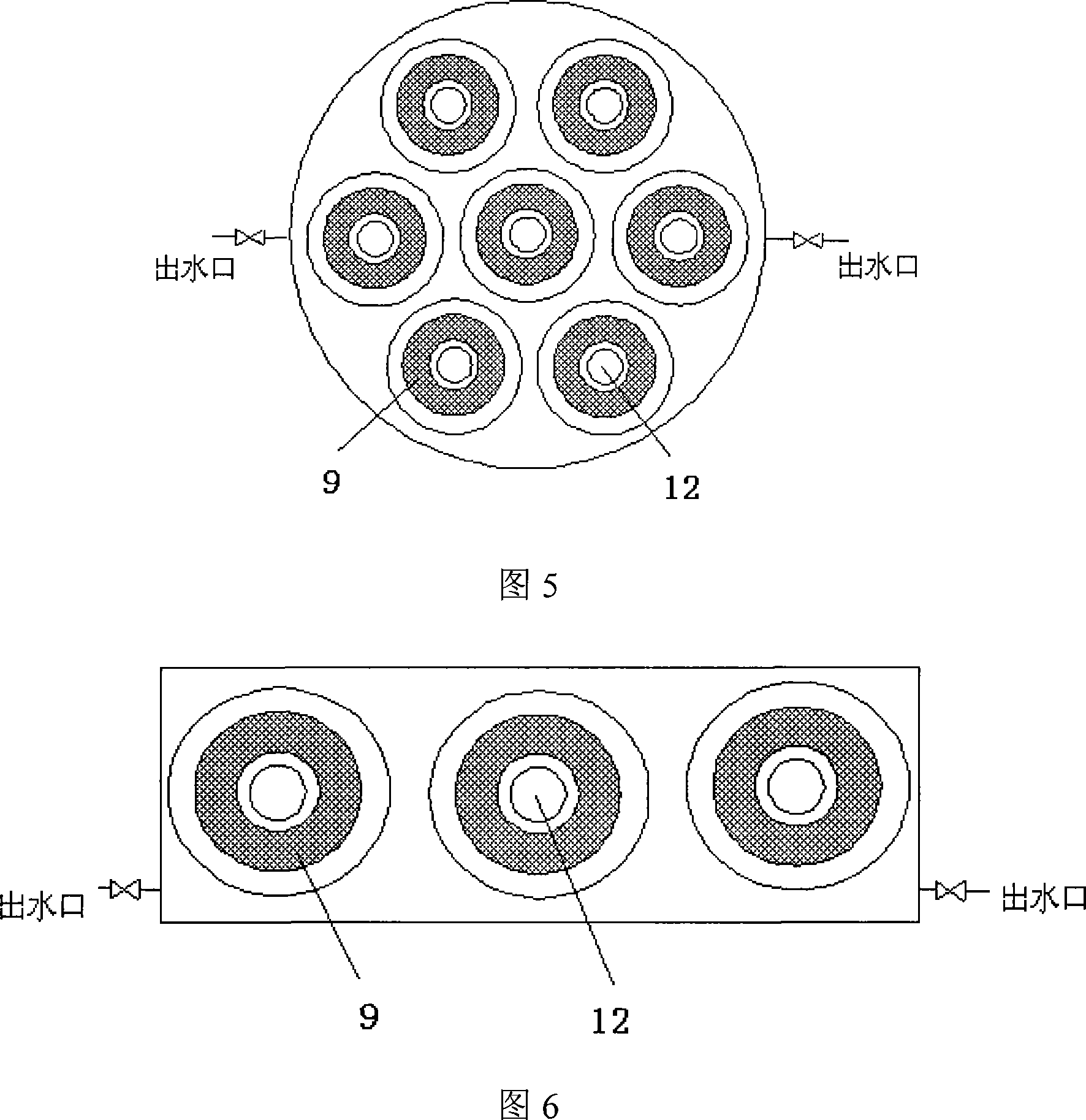

[0045] The membrane device used is a PVDF hollow fiber column membrane, the process is shown in Figure 5, and there are 7 membrane devices; the diameter of the cylindrical membrane type non-bubble oxygenator is , the PVDF hollow fiber membrane pore diameter is 0.01-0.2 μm, and the membrane wall thickness is 150 ~250μm, inner diameter 1.2mm, porosity: 50~85% air permeability: >1.0×10 -2 (cm 3 / cm 2 ·s·cmHg), the bubble point is 0.45MPa. The effective length of the membrane filament is 20cm, and the effective area of the membrane is 7×0.15m 2 . The test water is pure water, and the dissolved oxygen is considered to be close to zero at this time. The test gas is oxygen or air, and the pressure is controlled by the pressure reducing valve after passing through the gas storage tank. The hydraulic retention time in the membrane-type non-bubble oxygenator is 15min and 30min respectively, and the dissolved oxygen in the effluent is measured with a dissolved oxygen meter. The ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com