Method for preparing bore diameter/or bore pitch adjustable nano porous aluminum oxide film

A porous alumina and nanoporous technology, applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of limiting the application range of porous anodic aluminum oxide film, prevent aging and breakdown phenomena, and inhibit chemical Corrosion action, effect of oxidation current suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

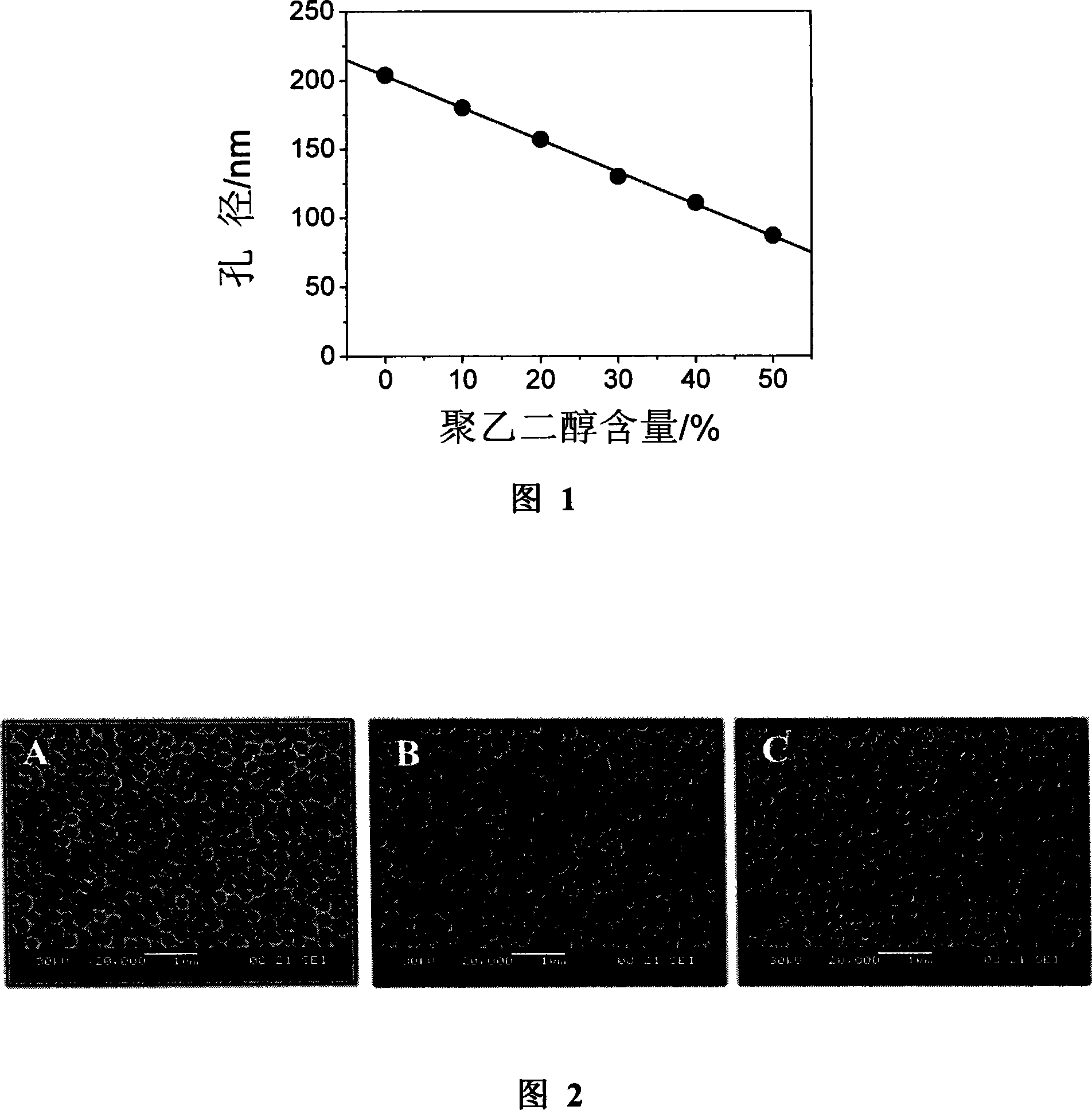

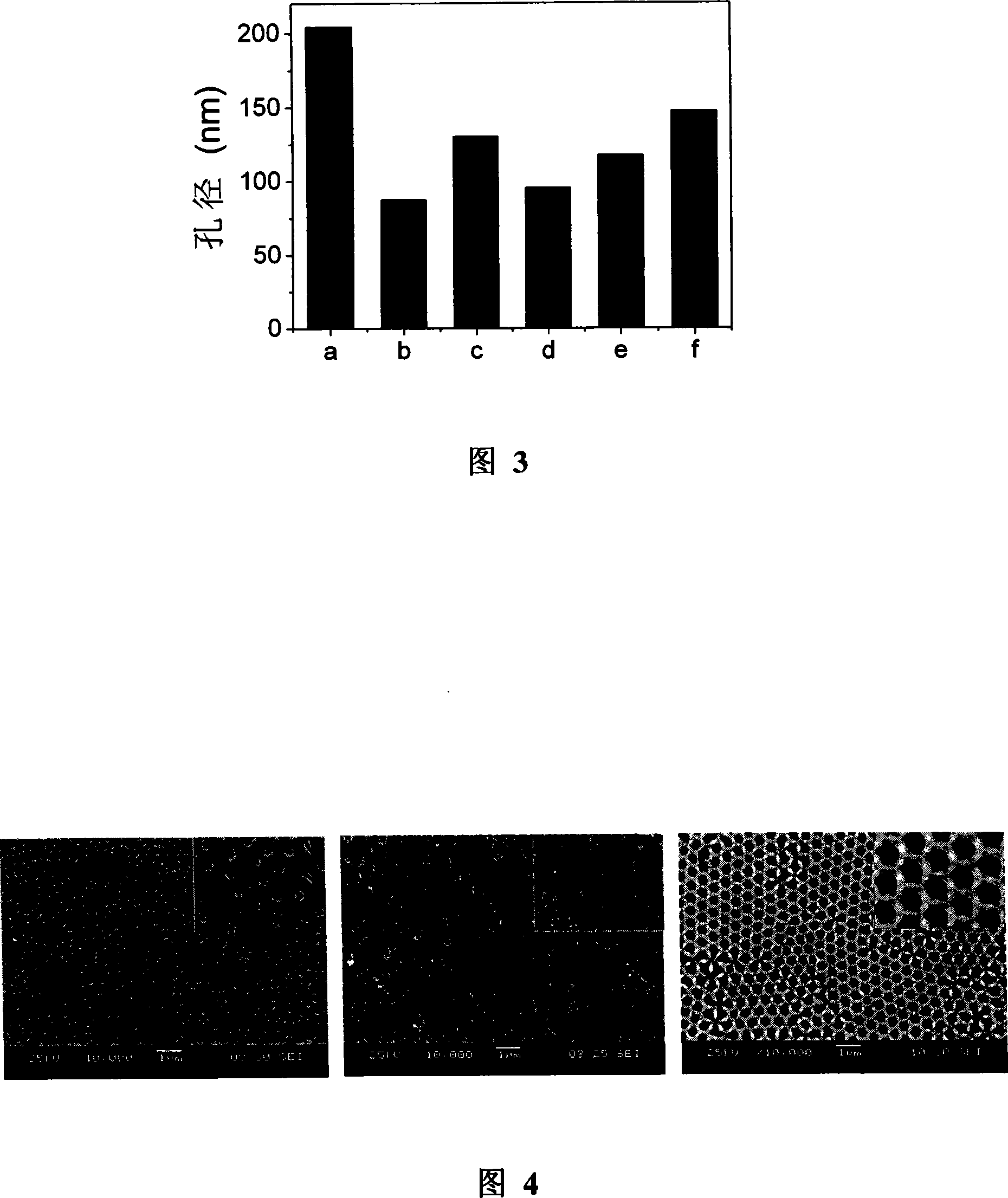

[0020] The steps for preparing porous alumina membrane provided by the present invention are as follows:

[0021] (1) The aluminum sheet is annealed at 500°C for 5 hours under the protection of a nitrogen atmosphere. Electrochemical polishing for 5 minutes in a 1:5 mixture of perchloric acid and ethanol at a potential of 20V.

[0022] (2) Install the aluminum sheet pretreated in step (1) as the anode in the U-shaped electrolytic cell system, add different concentrations of phosphoric acid as the electrolyte and different concentrations and different molecular weight polyethylene glycols as the protective agent. A clean large area aluminum sheet is used as the cathode to form a two-electrode electrolysis system;

[0023] (3) Use a constant temperature water bath to control the temperature of the electrolytic cell;

[0024] (4) Use a potentiostat to control the oxidation potential;

[0025] (5) Connect the power supply in step (4) to the aluminum anode and aluminum cathode in step (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com