Thin film transistor array base plate and its making method

A technology of thin film transistors and array substrates, which is applied in the field of self-repairing thin film transistor array substrates and its manufacturing, can solve the problems of rising manufacturing costs, increasing signal delays, increasing wiring film thickness, etc., to reduce production costs, reduce signal delays, The effect of increasing the number of masks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

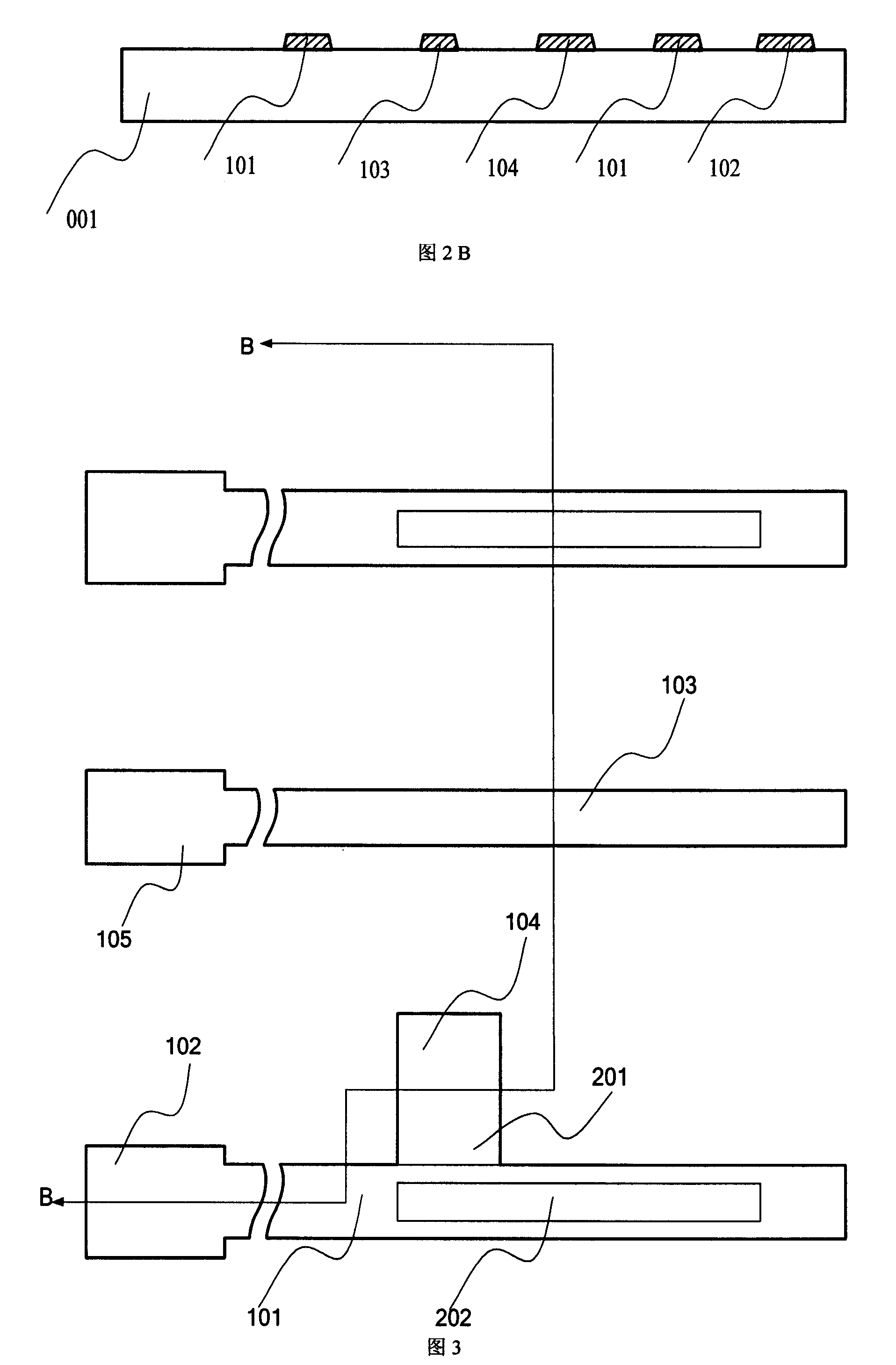

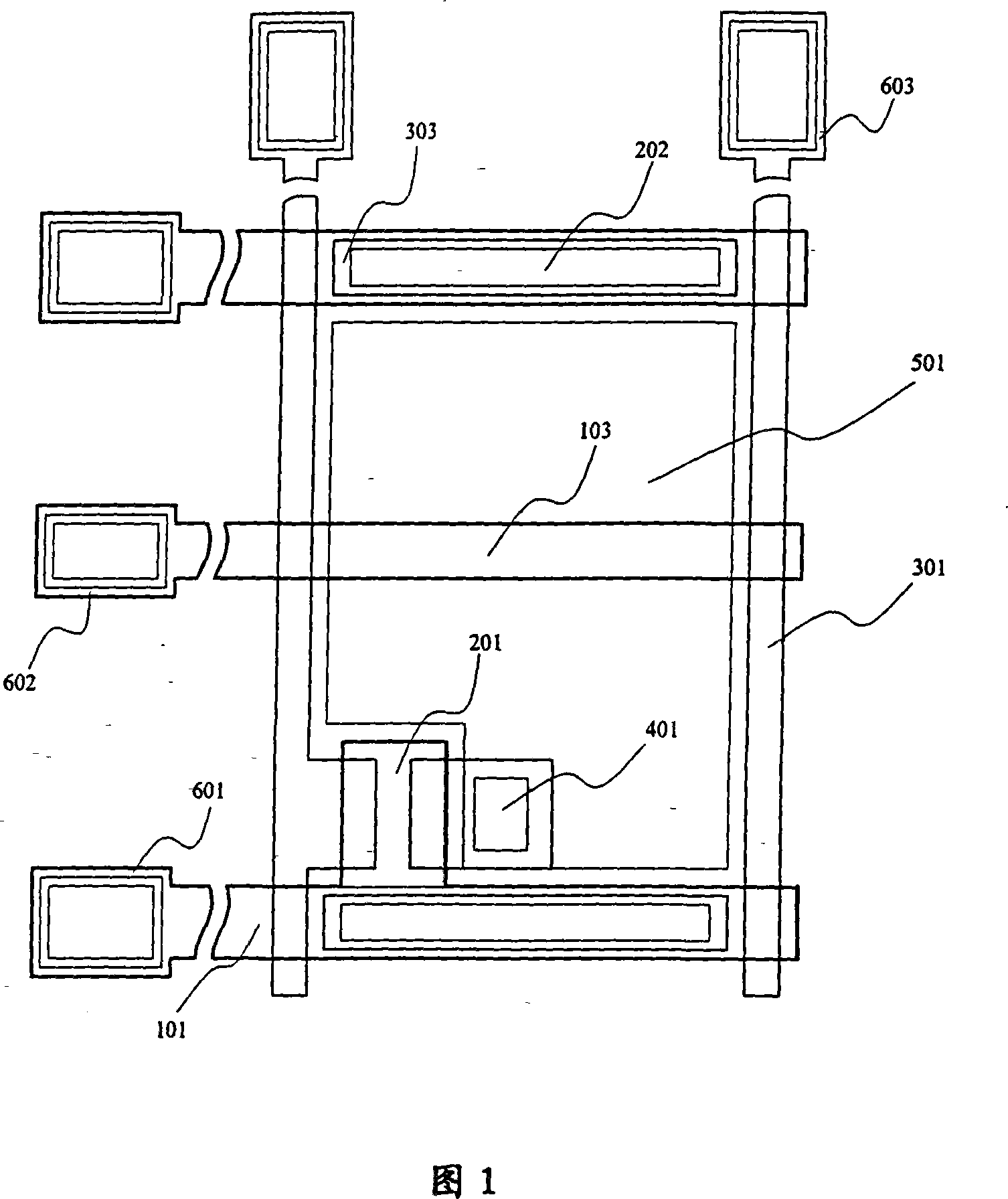

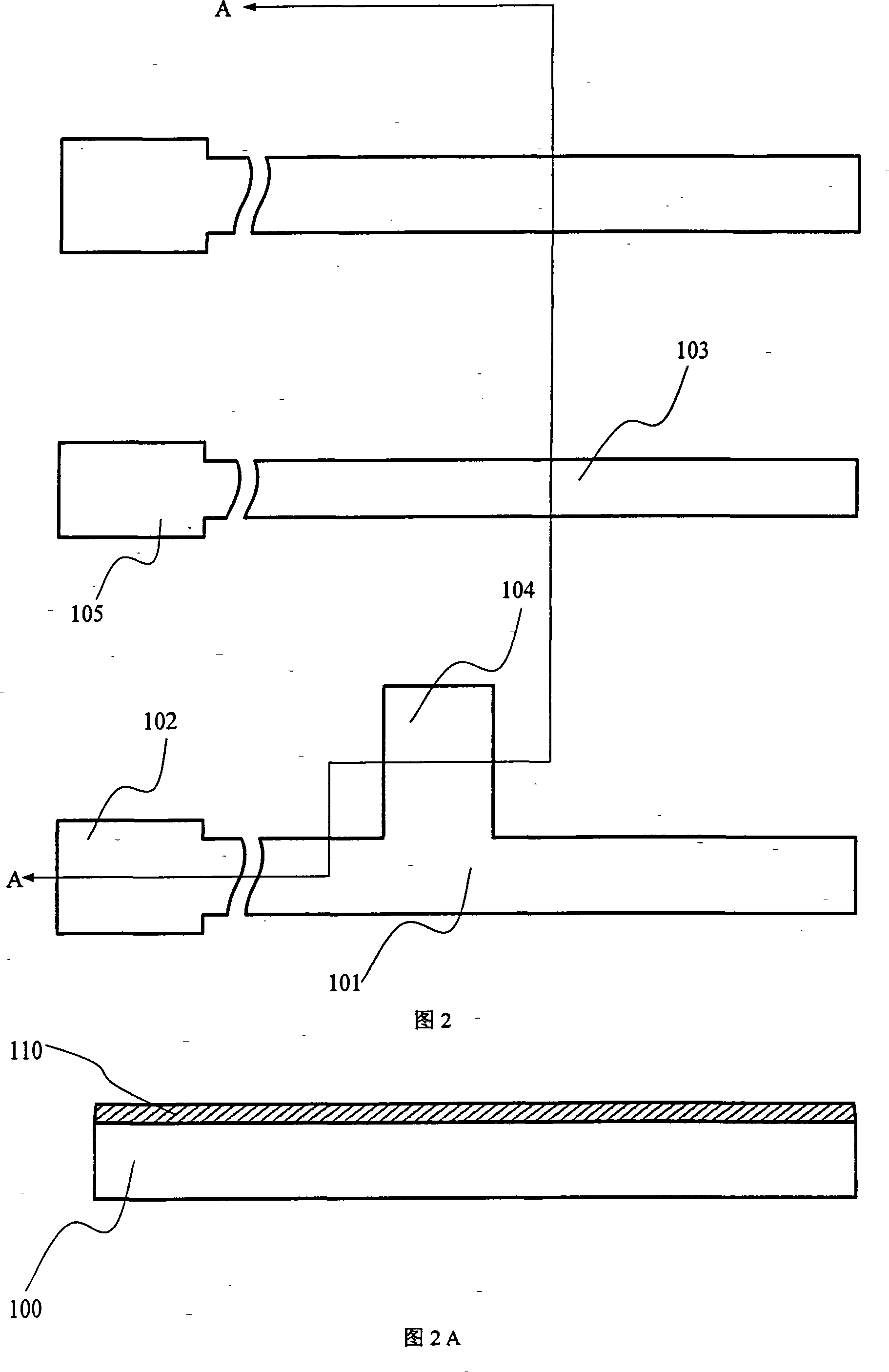

[0035] 1 to 6, the thin film transistor array substrate of the present invention has a scanning wiring conductive layer 110, an insulating layer 201, a data conductive layer 310, a passivation insulating layer 410 and a transparent conductive layer 510 sequentially formed on an insulating substrate 100, so that The insulating substrate 100 is a glass substrate or a plastic substrate; the scanning wiring 101 and the common electrode line 103 are formed on the scanning wiring conductive layer 110, and the gate insulating film 210, the semiconductor layer 220 and the ohmic In the contact layer 221 , the gate insulating film 210 does not cover or partly covers the scan wiring 101 , and the exposed scan wiring 202 is in direct electrical contact with the data wiring 303 on the above data conductive layer 310 .

[0036] The specific manufacturing method is described in conjunction with FIG. 2 to FIG. 6 .

[0037] First, referring to FIGS. 2, 2A and 2B, a scanning wiring conductive l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com