Environmental protection heat-insulating board and manufacturing method thereof

An insulation board, environmental protection technology, applied in the manufacture of insulation boards, the field of environmental protection insulation boards, can solve the problems of materials not being used effectively, achieve the effect of reducing density, increasing compressive strength, and improving insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

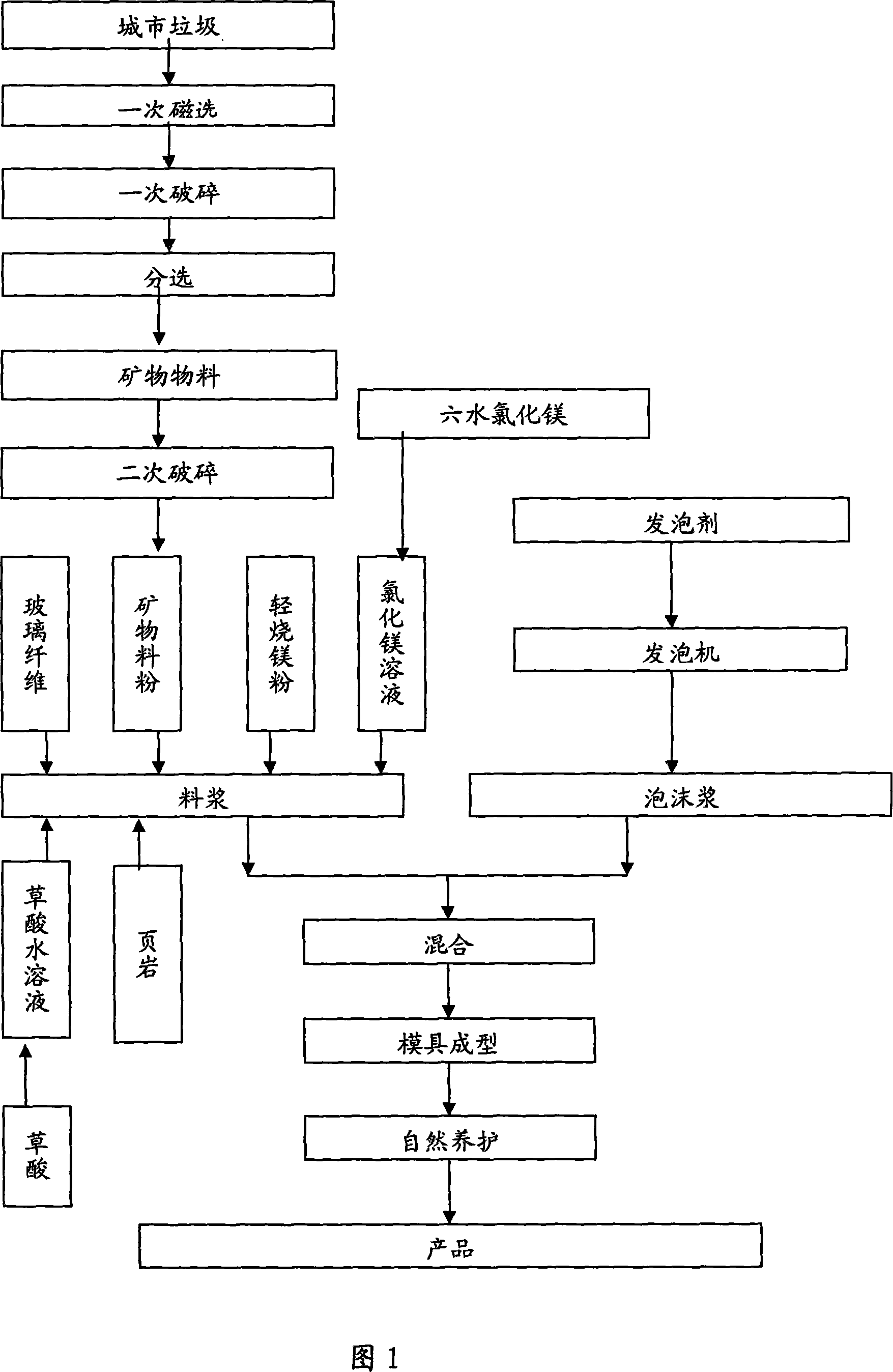

[0012] The preparation method of the mineral material powder derived from urban waste is: crushing and sorting the urban waste once, sorting out the mineral materials (materials composed of various inorganic salts and inorganic metal oxides), and separating the mineral materials The material is crushed into fine particles for the second time to form the above-mentioned mineral material powder derived from municipal waste.

[0013] The primary crushing can use a jaw crusher, which has a large crushing ratio, simple structure, uniform particle size of the crushed material, and the equipment itself has a simple structure, relatively high operating costs and maintenance costs, and is suitable for municipal waste processing. Crushing of materials with complex composition and properties.

[0014] If necessary, the primary crushing can be divided into two steps. The first step is to use the above-mentioned jaw crusher to crush large pieces into small pieces, and the second step is to...

Embodiment 1

[0032] Mineral powder from municipal waste: 200 kg;

[0033] Shale: 80 kg;

[0034] Glass fiber: 5 kg;

[0035] Lightly burned magnesium powder: 100 kg;

[0036] Oxalic acid: 1 kg;

[0037] Magnesium chloride aqueous solution of 32 degrees Baume: 75 kilograms;

[0038] Water reducer: 0.1 kg;

Embodiment 2

[0040] Mineral powder from municipal waste: 200 kg;

[0041] Shale: 50 kg;

[0042] Glass fiber: 15 kg;

[0043] Lightly burned magnesium powder: 150 kg;

[0044] Oxalic acid: 2 kg;

[0045] Magnesium chloride aqueous solution of 28-32 degrees Baume: 40 kg;

[0046] Water reducer: 0.2 kg;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com