Method for increasing yield of ethylene and propylene

A technology of propylene and ethylene, which is applied in the direction of ethylene production, chemical instruments and methods, and conversion of saturated carbon-carbon bonds to produce hydrocarbons. It can solve the problems of low yields of ethylene and propylene, and improve the yield of low-carbon olefins The effect of improving economy and good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

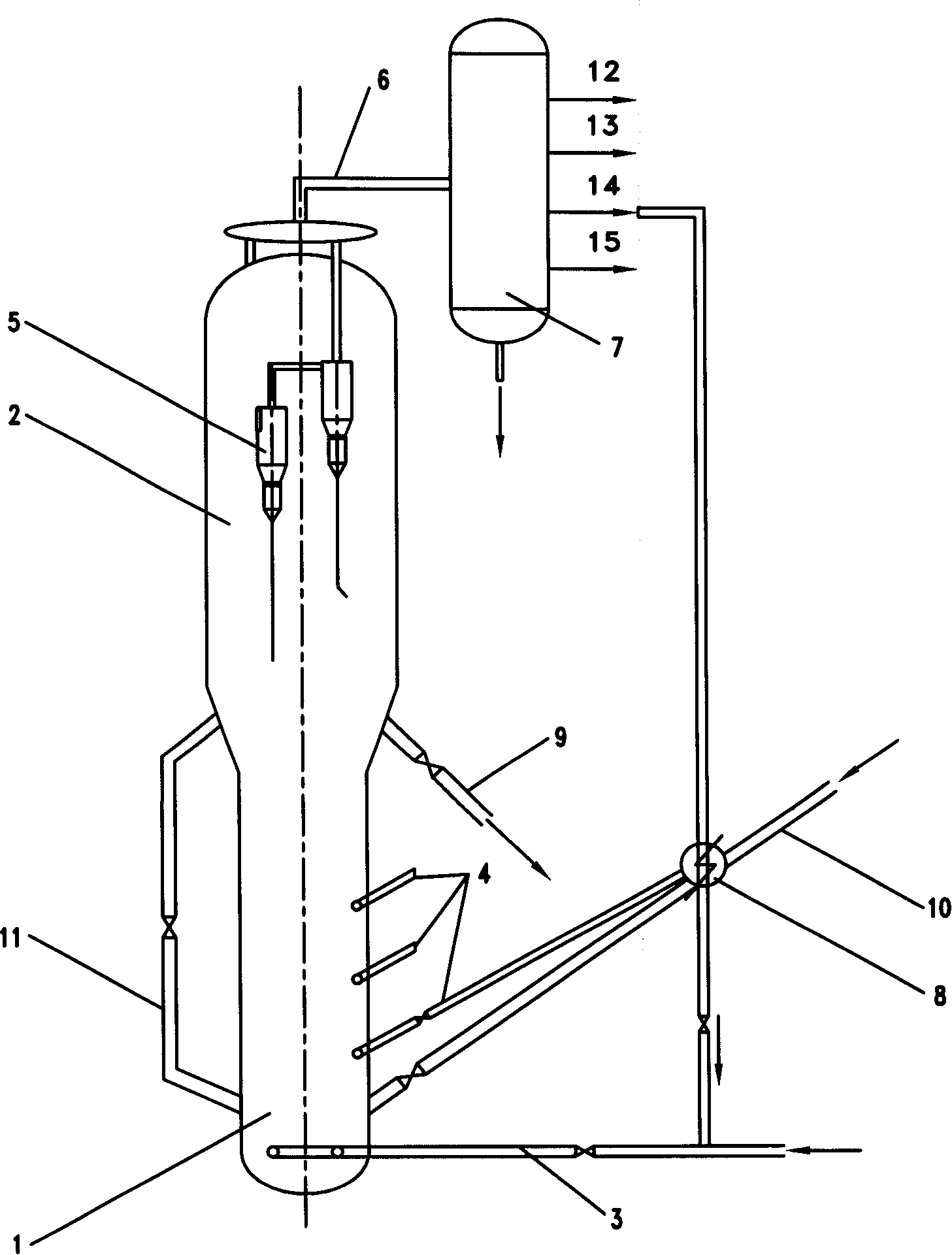

Image

Examples

Embodiment 1

[0022] In a small fast fluidized bed reactor, the spray-dried SAPO-34 molecular sieve was used as a catalyst, the reaction temperature was 450 ° C, and the mixture C 4 The volume ratio of hydrocarbons to methanol is 0.1:1, and the weight space velocity based on methanol is 1.5 hours -1 , the superficial linear velocity of the gas in the reaction zone is 2 m / s. The feeding position is at the bottom of the reactor, and enters the reactor to contact with the catalyst after passing through the porous distribution plate. The reaction product was analyzed by on-line gas chromatography. The reaction time was 10 minutes. The experimental results (weight percentage) were as follows: the conversion rate of methanol was 100%, the yield of ethylene was 20.2%, and the yield of propylene was 14.3%.

Embodiment 2

[0024] According to the conditions described in Example 1, the reactor type adopts a moving bed, the catalyst adopts 20-40 mesh ZSM-34 molecular sieves, the methanol is changed to dimethyl ether, and the reaction temperature is changed to 550 ° C, based on the weight of dimethyl ether Airspeed is 20 hours -1 , The superficial linear velocity of the gas in the reaction zone is 5 m / s, and the experimental results (weight percentage) are: the conversion rate of dimethyl ether is 97.5%, the yield of ethylene is 17.3%, and the yield of propylene is 7.1%.

Embodiment 3

[0026] According to the conditions described in Example 1, the reactor type adopts a dense-phase fluidized bed, and the reaction temperature is changed to 350 ° C, and the weight space velocity based on methanol is changed to 0.5 hours -1 , the superficial linear velocity of the gas in the reaction zone is 0.1 m / s. The experimental results (percentage by weight) are as follows: the conversion rate of methanol is 98.4%, the yield of ethylene is 13.1%, and the yield of propylene is 13.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com