Acrylic pressure sensitive adhesive composition

A technology for acrylic adhesives and compositions, applied in the direction of acid copolymer adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of deterioration of adhesion and durability reliability, and achieve excellent Durable reliability, no whitening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

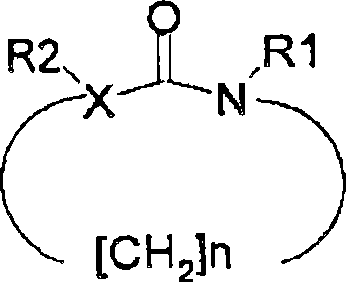

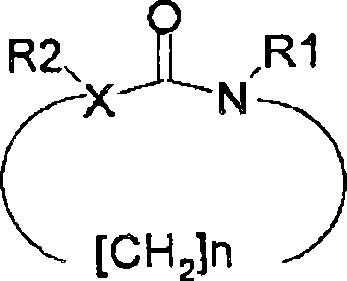

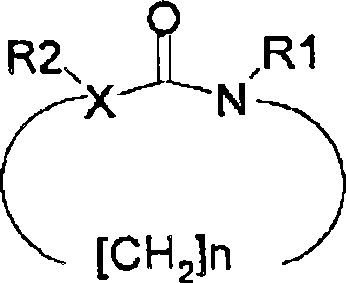

Method used

Image

Examples

Embodiment 1

[0065]

[0066] Into a 1L reactor equipped with a nitrogen reflux device and a temperature-controlled cooler, add 98.3 parts by weight of n-butyl acrylate (BA), 0.5 parts by weight of acrylic acid (AA) and 1.2 parts by weight of hydroxyethyl methacrylate (2-HEMA ) and 100 parts by weight of ethyl acetate (EAc) as a solvent. The reactor was purged with nitrogen for 1 hour to remove oxygen and maintained at 62°C. After homogenizing the mixture, 0.03 parts by weight of azobisisobutyronitrile (AIBN) diluted at a concentration of 50% in ethyl acetate was added as a reaction initiator. The reaction was carried out for 8 hours to obtain an acrylic acid copolymer.

[0067]

[0068] Lithium bis(trifluoromethanesulfonyl)imide and acetamide were mixed at a weight ratio of 1:1 at room temperature and left to stand for 12 hours to obtain a metal eutectic salt.

[0069]

[0070] To 100 parts by weight of the above-prepared acrylic copolymer, 0.5 parts by weight of trimethylolpropane...

Embodiment 2~15

[0074] The copolymerization was carried out under the conditions given in Table 1 and Example 1 below. Use urea in addition to acetamide and lithium bis(pentafluoroethanesulfonyl)imide, or use potassium bis(trifluoromethanesulfonyl)imide instead of lithium bis(trifluoromethanesulfonyl)imide to prepare room temperature low-eutectic molten salt. Preparation, mixing and lamination of the acrylic copolymer were carried out in a similar manner to Example 1. The durability reliability, surface resistance and haze measurement results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com