Cultivation device and method for adherent cell thin membrane of laboratory

A thin-film culture device and adherent cell technology, applied in the field of bioengineering, can solve the problems of increased cost, different priorities, and long exposure time of cells, and achieve the effects of reduced chance of contamination, uniform force, and strong representativeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

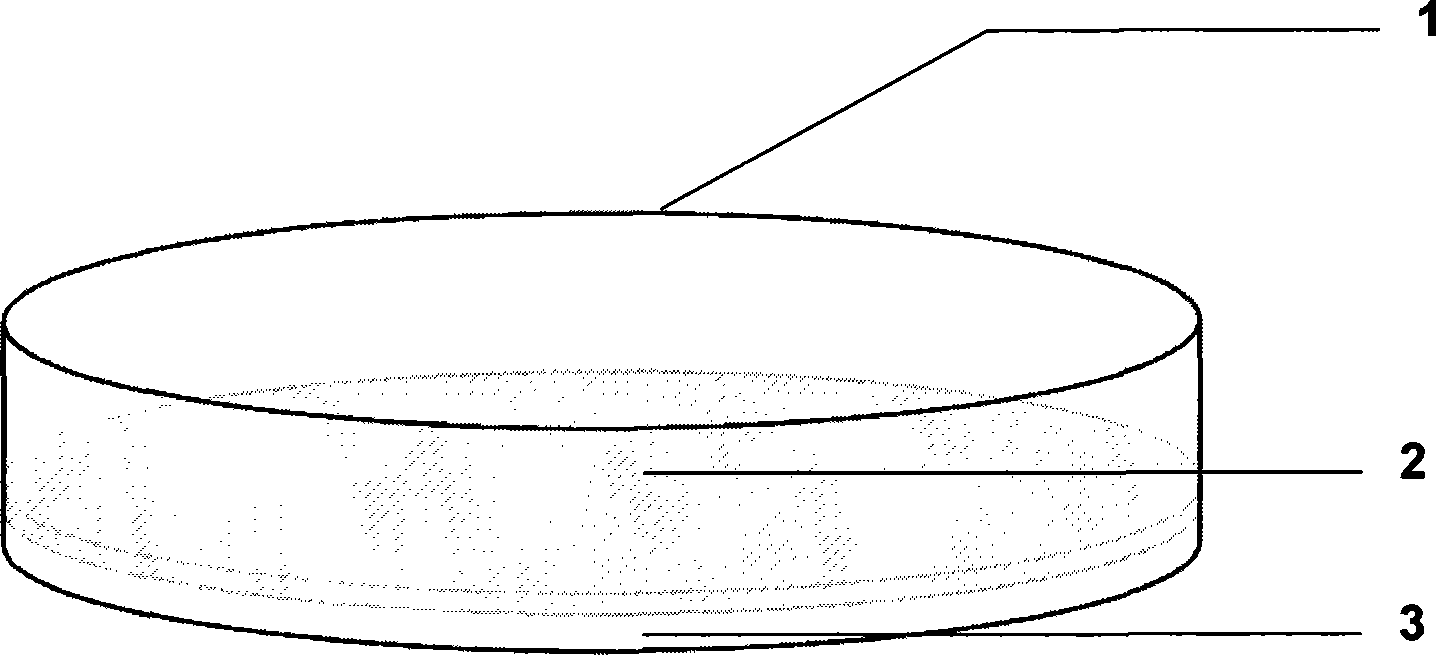

[0019] like figure 1 As shown, the laboratory adherent cell film culture device involved in this embodiment includes a plate 1 , an organic polymer film layer 2 , and an adhesive liquid layer 3 . The organic polymer film layer 2 is attached to the inner bottom surface of the petri dish 1 under the action of the adhesive liquid layer 3 .

[0020] The petri dish 1 is an ordinary petri dish, which can be made of glass or plastic.

[0021] The organic polymer film layer 2 can be selected from materials such as polyester, polyamino acid PGAc, PU, chitosan, cellulose po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com