Martensitic stainless steel composition, method for making amechanical part from said steel and resulting part

A technology of martensitic stainless steel and mechanical parts, which is applied in the field of alloy steel, can solve problems such as unrealizable, and achieve the effects of good tolerance, low sensitivity and good resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

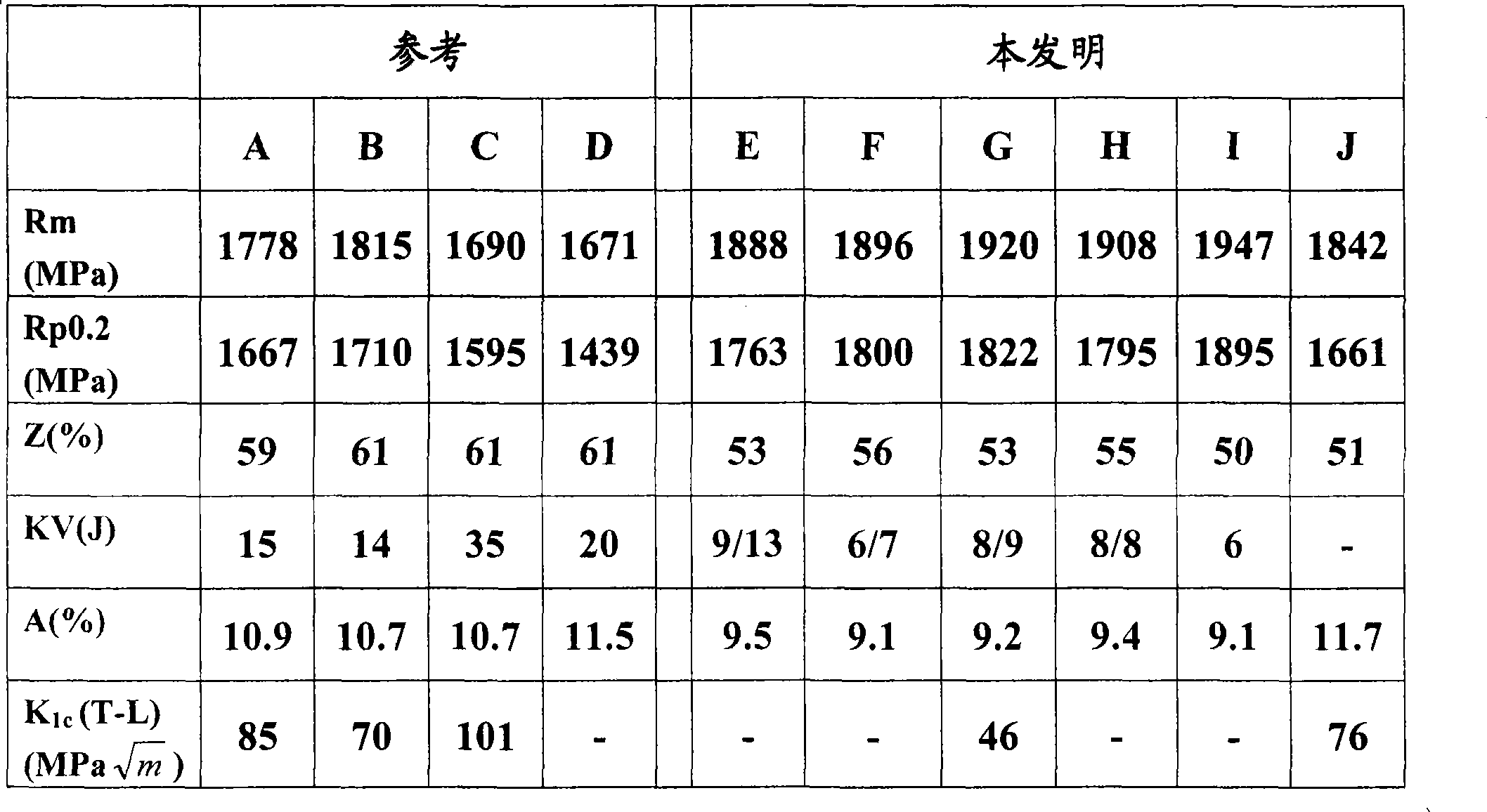

[0072] The present invention can be better understood by reading the following description.

[0073] Steels with extremely high strength are very sensitive to stress corrosion. The composition of the steel according to the invention makes it possible, by virtue of the generally increased corrosion resistance, to avoid the actual origin of stress corrosion cracking in atmospheric environments, which is the generation of hydrogen by the corrosion mechanism and the internal diffusion of this hydrogen leading to embrittlement of the metal . For this, the chromium and molybdenum contents are respectively at least 9% and 1.5%, preferably at least 10% and 2%, in this way a pitting index I.P. of at least 16.5 is obtained in the latter case (the Defined as I.P.=Cr+3.3Mo), as the pitting index of AISI 304 type austenitic stainless steel at 16-18% Cr. This is because a minimum chromium content of 9-11% is necessary in order to give steel resistance to corrosion in a humid atmosphere by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com