Highland barley essential oil and preparation of supercritical extract thereof

A technology of supercritical, highland barley bran oil, applied in food preparation, edible oil/fat, food science and other directions, can solve the problems of not talking about the production process of highland barley bran oil, not studying the literature report of highland barley bran oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

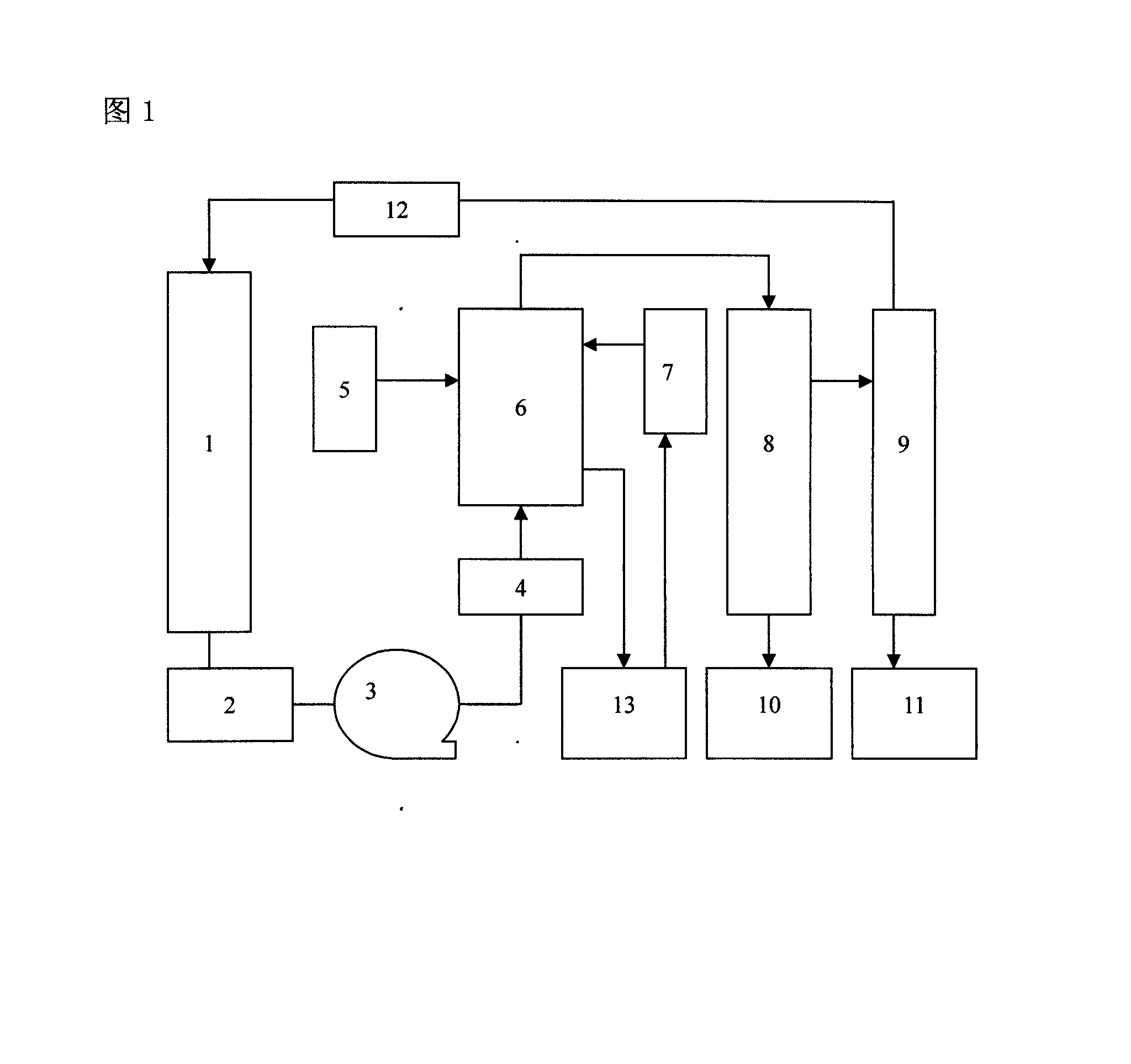

[0035] 200nm particle size in raw material tank 7, water content 10%, highland barley bran powder 60g (about 200ml) of impurity content 0.2% is put into extraction tank 6, and volume is 1L, and cosolvent water 2g is added extraction tank 6, then The extraction tank was preheated to 35°C. The main solvent carbon dioxide is liquefied from the storage tank 1 to the liquefier 2, and enters the preheater 4 through the high-pressure pump 3. The preheating temperature of the main solvent is the same as that of the extraction tank. After preheating, it enters the extraction tank 6 and is mixed with barley bran powder. Extract together with the co-solvent, the flow rate is controlled at 5L / h, the initial pressure is 80B as the main solvent, and then the pressure of the extraction tank is increased to 260B of the critical pressure. The temperature of the separator and the product storage tank are both 32°C. The pressure of the separator 8 is constant at 220 Bar, and the pressure of the ...

Embodiment 2

[0037] Put the highland barley bran powder 60g (about 200ml) with a particle size of 600nm in the raw material tank 7, a water content of 0.001%, and an impurity content of 3% into the extraction tank 6, with a volume of 1L, and add the cosolvent isododecane 100g into the extraction tank 6 , and then preheat the extraction tank to 80°C. The main solvent carbon dioxide is liquefied from the storage tank 1 to the liquefier 2, and enters the preheater 4 through the high-pressure pump 3. The preheating temperature of the main solvent is the same as that of the extraction tank. After preheating, it enters the extraction tank 6 and is mixed with barley bran powder. Extract together with the co-solvent, the flow rate is controlled at 60L / h, the initial pressure is 90B as the main solvent, and then the pressure of the extraction tank is increased to 200B of the critical pressure, and the temperature of the separator and the product storage tank are both 40°C. The pressure of the separ...

Embodiment 3

[0039] Put 4mm particle size in raw material tank 7, water content 5%, highland barley bran powder 60g (about 200ml) of impurity content 2% into extraction tank 6, volume is 1L, add co-solvent ethyl acetate 20g into extraction tank 6, The extraction tank was then preheated to 65°C. The main solvent ethylene is liquefied from the storage tank 1 to the liquefier 2, and enters the preheater 4 through the high-pressure pump 3. The preheating temperature of the main solvent is the same as that of the extraction tank. After preheating, it enters the extraction tank 6 and is mixed with the barley bran powder. Extract with the co-solvent, the flow rate is controlled at 38L / h, the pressure at the beginning is 30B as the main solvent, and then the pressure of the extraction tank is increased to 90B of the critical pressure. The temperature of the separator and the product storage tank are both 42°C. The pressure of separator 8 was constant at 50Bar, and the pressure of separator 9 was i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com