Discharge gas surface biofiltration scouring method and device

A biological filtration and purification device technology, applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve the problems of restricting the practical application of gas-phase biological filtration technology in industry, unstable long-term operation performance, high construction and operation costs, etc., to achieve No secondary pollution, short residence time of waste gas and large treatment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

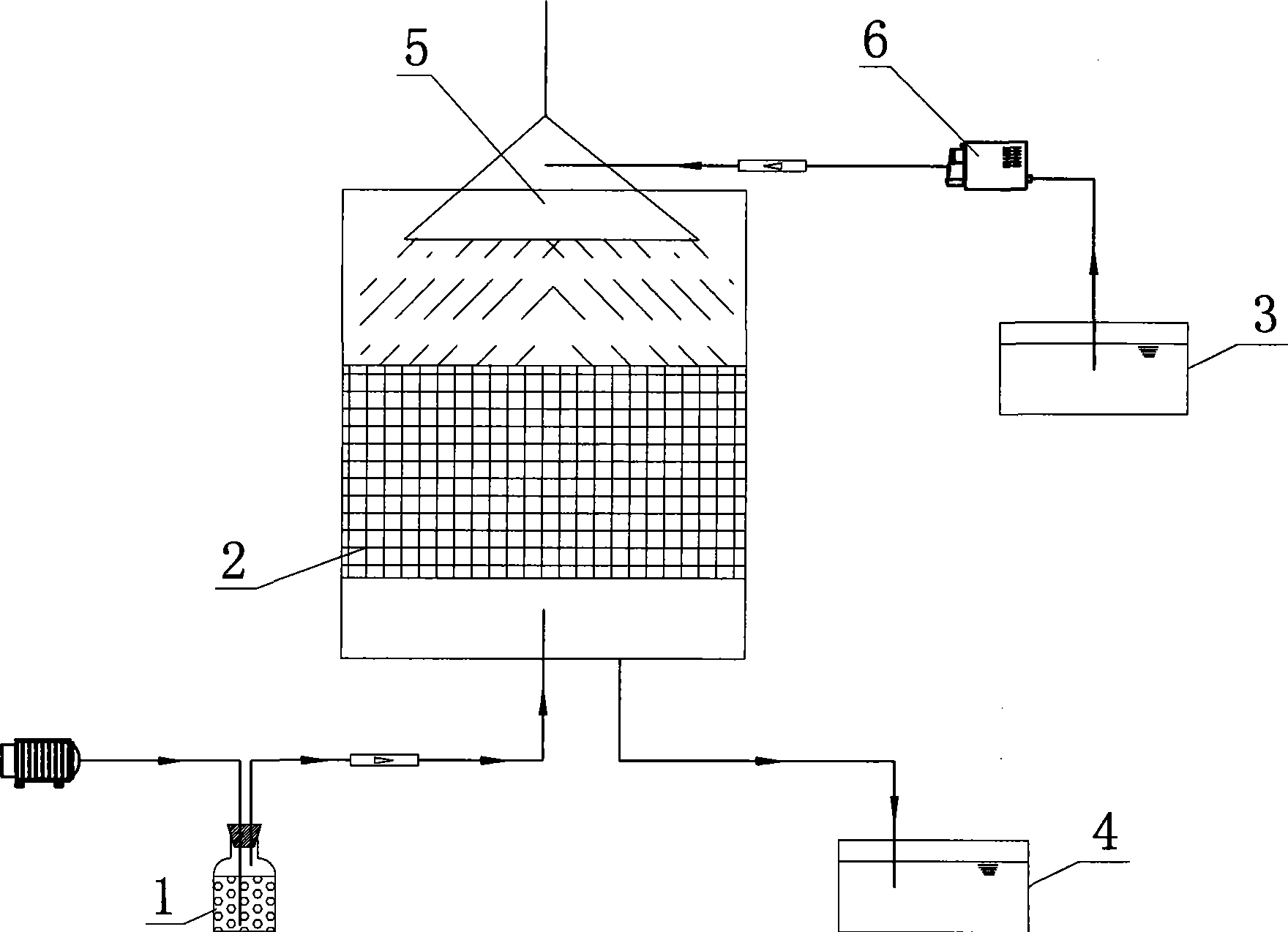

[0027] Embodiment 1: see figure 1 As shown, the single-stage process flow treatment concentration is 2000mg / m 3 ether exhaust gas. Adopting porosity 90%, the cuboid polyurethane sponge that aperture is 20 orders (about 1 millimeter) is used as the filter material of biological filter medium layer 2, and specific size is high and is 20cm, and width is 10cm, and thickness is 5cm, and volume is 1L. After the exhaust gas passes through the exhaust gas humidification unit 1, it passes through the biological filter medium layer 2 vertically and horizontally, and the flow rate is about 10m 3 / day, the air velocity of the empty bed is 0.5cm / s, and the residence time of the empty bed is 10s. The amount of nutrient solution containing nitrogen, phosphorus and other nutrient elements and buffers added every day is 1L, and the control unit 6 sprays evenly on the whole biological filter medium layer from the top of the filler through the nutrient solution supply unit 3 and the nutrient s...

Embodiment 2

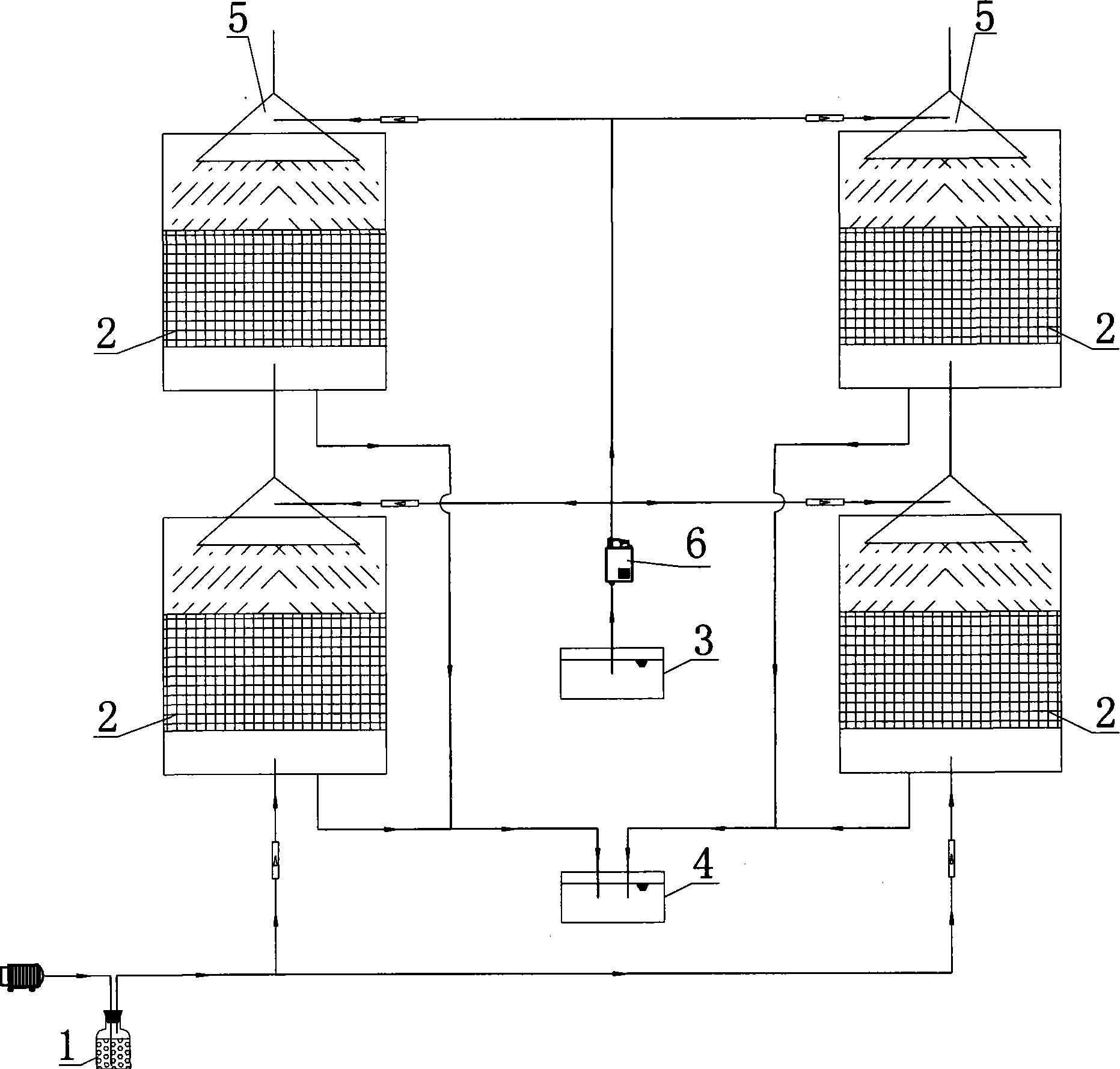

[0029] Example 2: see figure 2 As shown, the concentration of 2000mg / m 3 h 2 S and 500mg / m 3 Mixed waste gas of toluene. The porosity of filter material 2 all adopts 90% of filter material, and the aperture is the cuboid polyurethane sponge of 20 orders (about 1 millimeter), and height is 20cm, and width is 10cm, and thickness is 5cm, and volume is 1L (same implementation example 1). The exhaust gas vertically passes through the filter layer of the first-stage biological filter medium layer 2, and the outlet gas of the first stage flows through the second-stage biological filter medium layer 2, and the H in the outlet air of each stage is measured 2 S and toluene concentrations. Exhaust gas flow is about 1m 3 / day, the air velocity of the empty bed is 0.5cm / s, and the residence time of the empty bed is 10s. Each level supplements 1.5L of nutrient solution containing nitrogen, phosphorus and other nutrient elements and buffers every day. The control unit 6 sprays evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com