Technique for preparing willow leaf tabersonine

A technology of glycyrrhizine and preparation process is applied in the field of preparation of plant extracts, can solve the problems of long production cycle, complex process, low product yield and the like, and achieves short production cycle, simple chemical steps and product yield. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

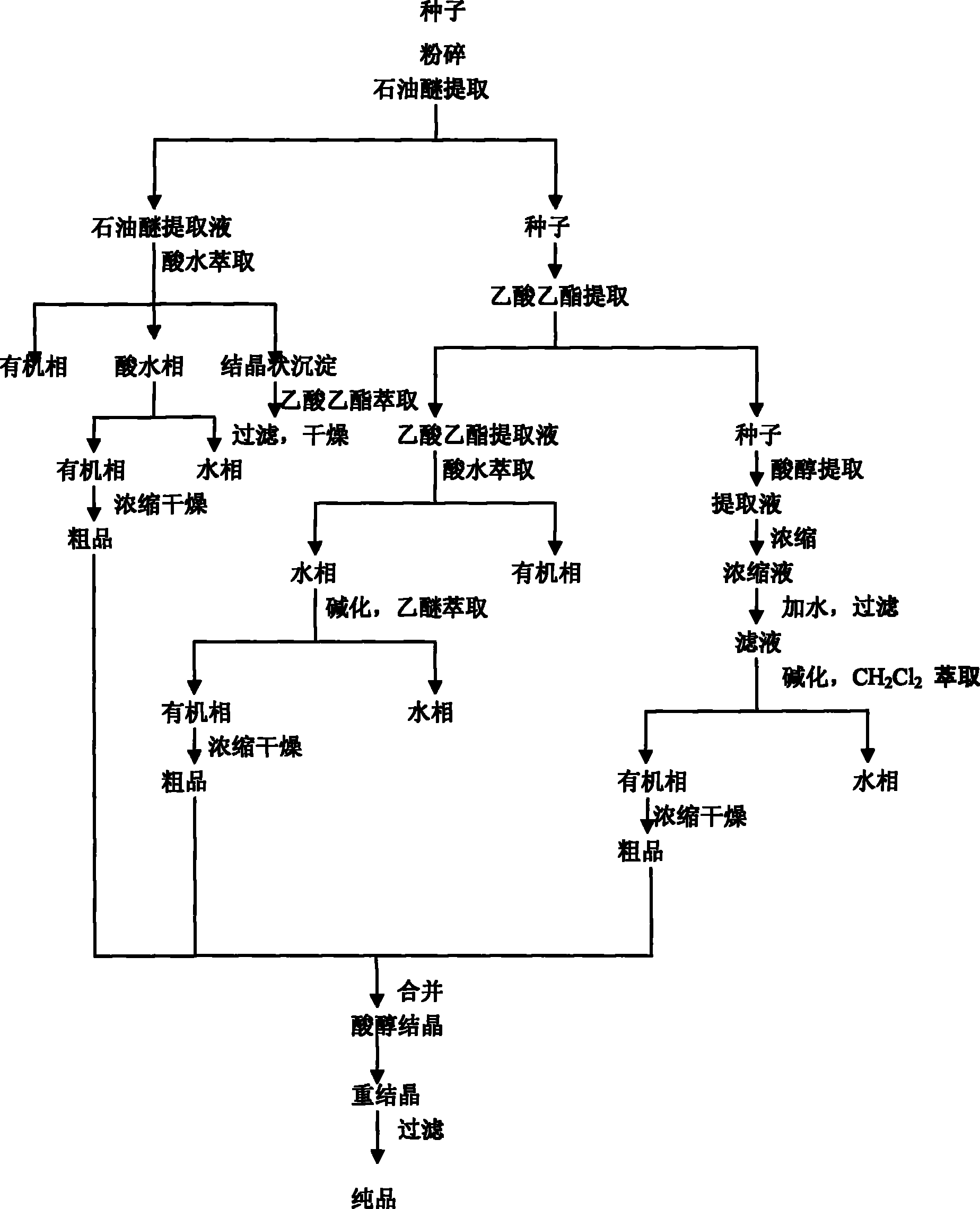

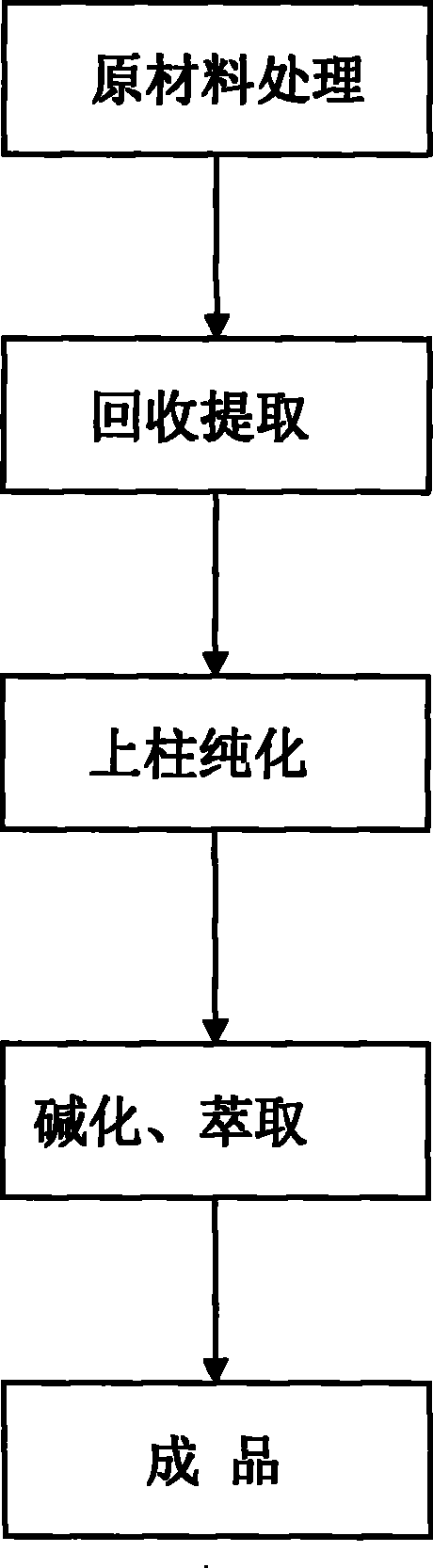

Method used

Image

Examples

Embodiment 1

[0017] A kind of preparation technology of willow leaf glycyrrhizin, comprises the following steps successively,

[0018] 1. Raw material pretreatment: African potato fruits are harvested when they are ripe or about to be ripe, dried, crushed, and dried through a 40-mesh sieve for later use;

[0019] 2. Reflux extraction: Take 200 grams of seed powder, and use 4 times, 3 times, and 3 times the volume of n-hexane to reflux extract three times at 50° C. for 1 hour each time. Filtrate, combine the filtrates, wash the n-hexane layer three times with 750 ml of aqueous hydrochloric acid solution with a mass ratio of 1%, reclaim the organic solvent, and combine the acid aqueous solution for subsequent use;

[0020] 3. Purification on the column: select D101 macroporous adsorption resin, directly load the sample with acid water, wash the impurities with water, elute the product with 80% ethanol by mass ratio, and concentrate the eluent under reduced pressure to remove ethanol;

[002...

Embodiment 2

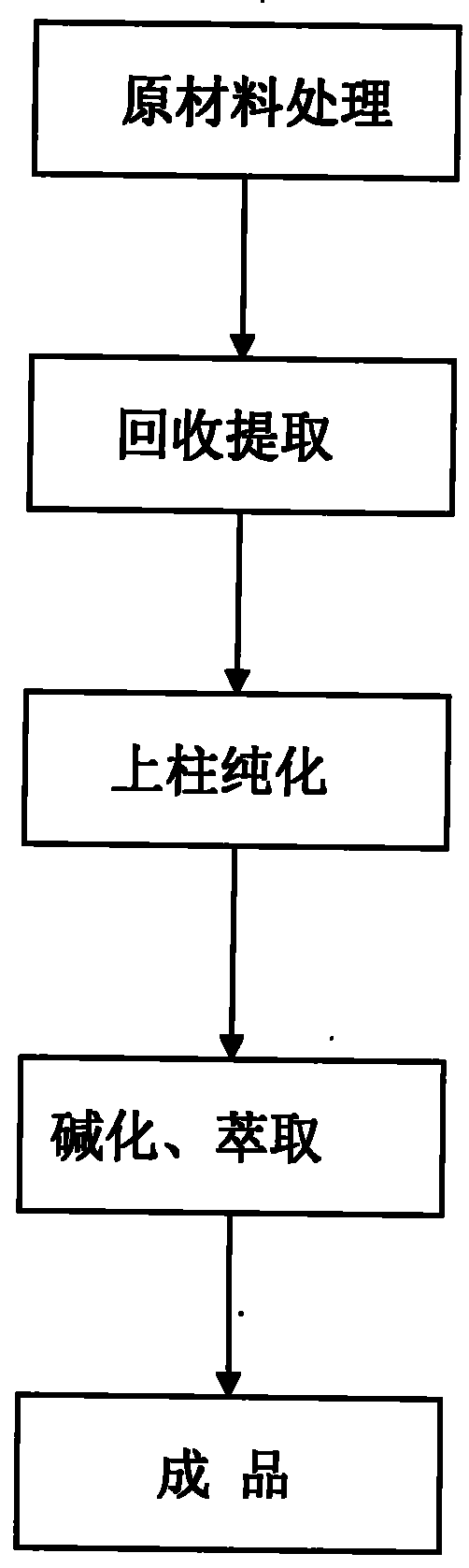

[0023] A kind of preparation technology of willow leaf glycyrrhizin, comprises the following steps successively,

[0024] 1. Raw material pretreatment: African potato fruit is harvested when it is ripe or about to mature, dried, crushed, and dried through a 50-mesh sieve for later use;

[0025] Two, reflux extraction: get 200 grams of seed powder, use 4 times, 3 times, 4 times of mass ratio of volume respectively to be the methanol aqueous solution 60~70 ℃ of 80% reflux extraction three times, be respectively 1 hour, 1.5 hours and 1 hour. Filtrate, combine the filtrates, concentrate under reduced pressure until there is no alcohol, add 500ml of hydrochloric acid aqueous solution with a mass ratio of 1.5%, and set aside;

[0026] 3. Purification on the column: choose XDA-6 macroporous adsorption resin, directly load the sample with acid water, wash the impurities with water, elute the product with 90% ethanol water solution by mass ratio, and concentrate the eluent under reduce...

Embodiment 3

[0029] A kind of preparation technology of willow leaf glycyrrhizin, comprises the following steps successively,

[0030] 1. Raw material pretreatment: African potato fruit is harvested when it is ripe or about to mature, dried, crushed, and dried through a 50-mesh sieve for later use;

[0031] Two, reflux extraction: get 200 grams of seed powder, use 3 times, 2.5 times, 2.5 times of mass ratio of volume respectively to be 90% ethanol aqueous solution 70 ℃ of reflux extraction three times, be respectively 1 hour, 50 minutes and 1 hour. Filter, combine the filtrates, concentrate under reduced pressure until there is no alcohol smell, add 500ml of hydrochloric acid aqueous solution with a mass ratio of 0.5%, and set aside;

[0032] 3. Purification on the column: choose XDA-7 macroporous adsorption resin, directly load the sample with acid water, wash the impurities with water, elute the product with 60% ethanol, and concentrate the eluent to remove ethanol;

[0033] 4. Alkalini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com