Aqueous composite paint containing amphiphilic fluorine-containing acrylate blocking copolymer and preparation thereof

A block copolymer, non-fluorine acrylate technology, applied in coatings, latex paints, etc., can solve the problem of weakening the modification effect of fluorine-containing groups, difficult for fluorine-containing groups to reach the surface of the coating film, weak coating adhesion, etc. The problem is to reduce the probability that the fluorine-containing group is difficult to reach the coating surface, reduce the performance of the coating and the adverse impact on the environment, and improve the adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

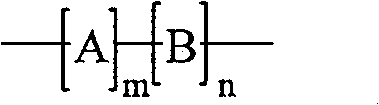

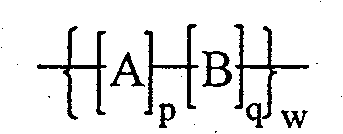

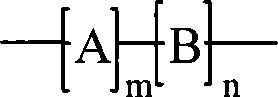

Method used

Image

Examples

Embodiment 1

[0062] Add 10 parts of the first monomer methacrylic acid, 1 part of initiator ammonium persulfate, 4 parts of RAFT reagent 4-dithiobenzoic acid (4-cyanovaleric acid) ester and 50 parts of solvent water in a 100ml three-necked flask . Nitrogen was passed for 15 minutes, and then frozen in an ice-water bath. After repeated evacuation-nitrogen for 3 times, the tube was vacuum-sealed. Under magnetic stirring, react in an oil bath at 70°C for 6 hours to obtain a macromolecular RAFT reagent.

[0063] 100 parts of trifluoroethyl methacrylate as the second monomer, 0.2 parts of ammonium persulfate as the initiator and 200 parts of solvent water were continuously added to the above reactor. Nitrogen was passed for 15 minutes, and then frozen in an ice-water bath. After repeated evacuation-nitrogen for 3 times, the tube was vacuum-sealed. Under magnetic stirring, react in an oil bath at 70°C for 12 hours to obtain a fluorine-containing acrylate block copolymer emulsion.

[0064] Tak...

Embodiment 2

[0066] Add 10 parts of isobutyl methacrylate, 100 parts of hexafluorobutyl methacrylate, 2 parts of initiator potassium persulfate, 200 parts of solvent water and 2.5 parts of emulsifier ammonium lauryl sulfate into a 100 ml three-necked bottle. Nitrogen was passed for 15 minutes, and then frozen in an ice-water bath. After repeated evacuation-nitrogen for 3 times, the tube was vacuum-sealed. Under magnetic stirring, react in an oil bath at 70°C for 12 hours to obtain a fluorine-containing acrylate random copolymer emulsion.

[0067] Get 50 parts of fluorine-containing acrylate random copolymer emulsions, 50 parts of fluorine-containing acrylate block copolymers obtained in Example 1, 50 parts of titanium dioxide, 2 parts of defoaming agent silicone oil, 1 part of dispersant sodium acrylate, water 60 parts; Stir to mix evenly to obtain a composite coating. The post-test performance of the coating film is as follows: adhesion level 1, contact angle with water 94°, pencil hardn...

Embodiment 3

[0069] Add 15 parts of the first monomer hydroxyethyl methacrylate, 0.8 parts of the initiator 4,4'-azobis(4-cyanovaleric acid), and RAFT reagent 4-dithiobenzoic acid into a 100ml three-necked flask 4 parts of (4-cyanovaleric acid) ester and 100 parts of solvent water. Nitrogen was passed for 15 minutes, and then frozen in an ice-water bath. After repeated evacuation-nitrogen for 3 times, the tube was vacuum-sealed. React in an oil bath at 70° C. for 6 h under magnetic stirring to obtain a macromolecular RAFT reagent solution.

[0070] Continue to add 100 parts of the second monomer dodecafluoroheptyl methacrylate in the above-mentioned reactor, 0.5 parts of initiator 4,4'-azobis (4-cyanovaleric acid) and 150 parts of solvent water. Nitrogen was passed for 15 minutes, and then frozen in an ice-water bath. After repeated evacuation-nitrogen for 3 times, the tube was vacuum-sealed. React in an oil bath at 70° C. for 12 hours under magnetic stirring to obtain a fluorine-contain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com