Silicone exterior wall paint and preparation method thereof

A technology of exterior wall paint and silicone, applied in the direction of coating, latex paint, etc., can solve the problems of dust and suspended particle pollution, high porosity of the coating layer, poor air quality, etc., to reduce porosity and improve stain resistance The effect of soiling and increasing compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

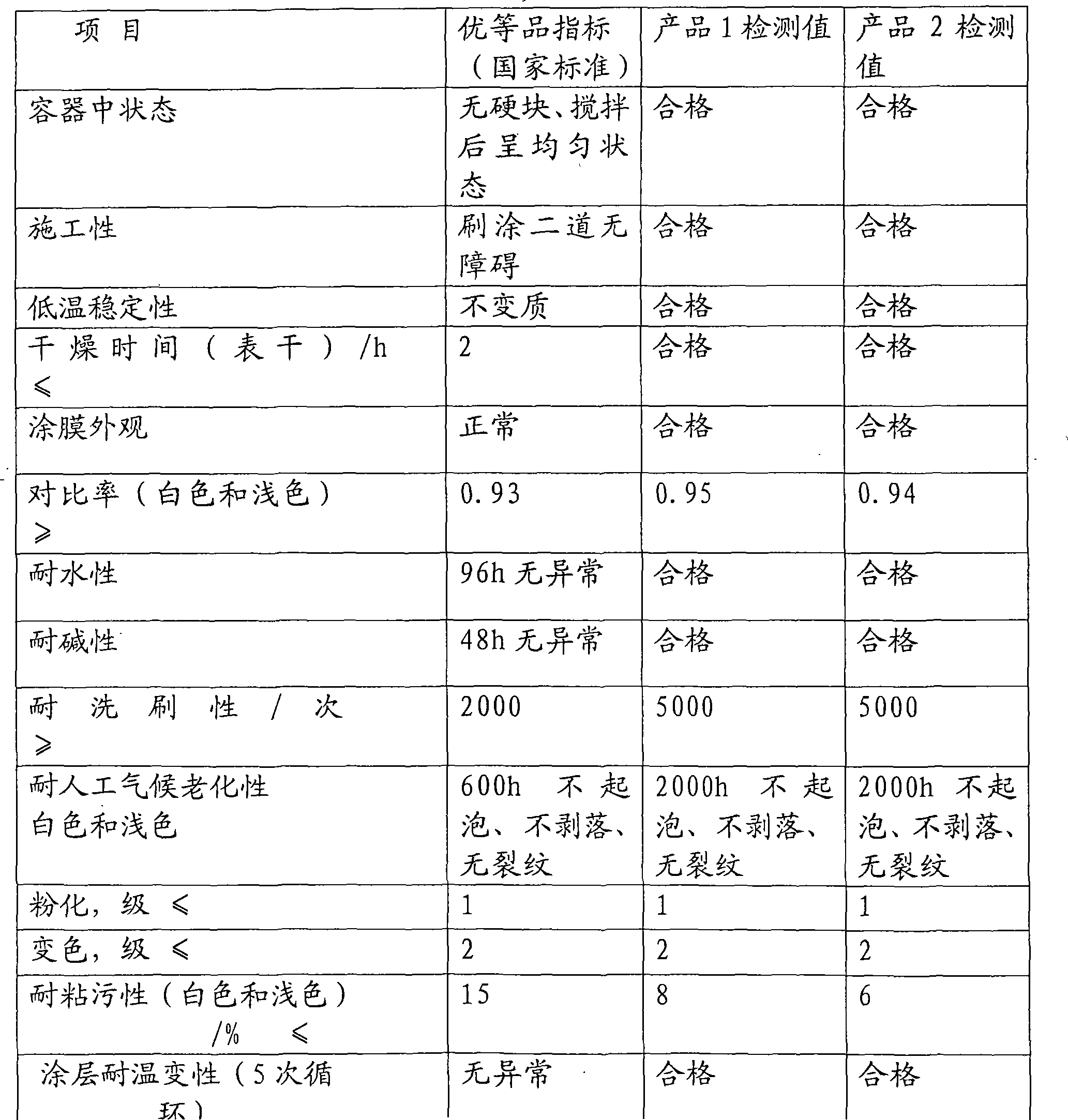

Examples

Embodiment 1

[0024] 1. Silicone resin exterior wall coating formula:

[0025] Raw material name dosage KG

[0026] water 220

[0027] Dispersant / Wetting Agent 7

[0028] thickener 11

[0029] Potassium methyl silicate aqueous solution 1

[0030] Antifoam 2

[0031] Coalescent 6

[0032] Co-solvent 7

[0033] Rutile titanium dioxide 210

[0034] Heavy calcium 140

[0036] Pure silicone resin emulsion (German Wacker SILRES BS43N) 130

[0037] Silicone modified polysiloxane emulsion 40

[0038] Preservatives 6

[0039] Acrylic Polymer Emulsion 180

[0040] Total 1000

[0041] 2. Preparation method

[0042]Weigh various raw materials according to the above formula and dosage, adjust the speed of the dispersion tank agitator to 800-900 rpm, mix water, dispersant, wetting agent, thickening agent, potassium methyl silicate aqueous solution, defoamer, Add film-forming aids and co-solvents into the dispersion tank together, gradually increase the stirrin...

Embodiment 2

[0044] 1. Silicone resin exterior wall coating formula

[0045] Raw material name dosage KG

[0046] water 210

[0047] Dispersant / Wetting Agent 7

[0048] thickener 11

[0049] Potassium methyl silicate aqueous solution (1:3 water) 1

[0050] Antifoam 2

[0051] Coalescent 6

[0052] Co-solvent 7

[0053] Rutile titanium dioxide 210

[0054] Heavy calcium 140

[0056] Pure silicone resin emulsion (SILRES BS43N from Wacker, Germany) 110

[0057] Paste isooctyltriethoxysilane mixture 40

[0058] Silicone modified polysiloxane emulsion 20

[0059] Preservatives 6

[0060] Acrylic Polymer Emulsion 180

[0061] Total 1000

[0062] 2. Preparation method

[0063] Weigh various raw materials according to the above formula and dosage, adjust the speed of the dispersion tank agitator to 800-900 rpm, mix water, dispersant, wetting agent, thickening agent, potassium methyl silicate aqueous solution, defoamer, Add film-forming aids and co-solv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com