Method for producing fuel ethanol by using lycoris plants

A technology of Amaryllis genus plants and fuel ethanol, applied in the direction of microorganism-based methods, biofuels, biochemical equipment and methods, etc., to achieve the effects of high alcohol yield, convenient operation, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

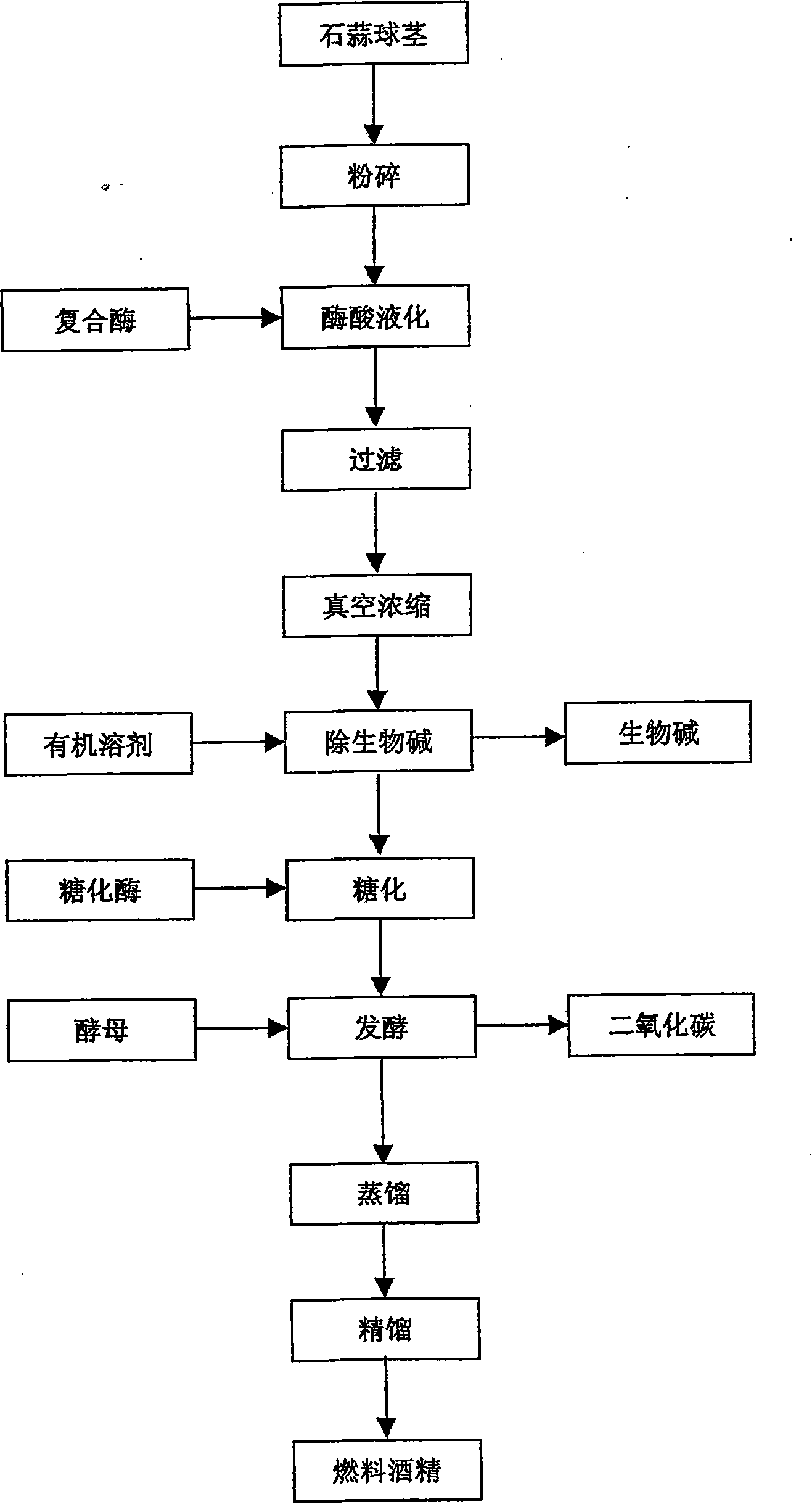

Method used

Image

Examples

Embodiment 1

[0028] (1) select the high starch content, no mildew and rot, the fresh spherical scale base of Amaryllis plant without disease and insect damage, after cleaning, removing impurities, draining water, weigh 100Kg of material. (2) Pulverization: add 300Kg of water, and use a cutting pulverizer to pulverize Lycoris balls twice, with a coarse pulverization ratio of 1:13 and a fine pulverization ratio of 1:35. 30~60 minutes; (3) enzymatic acid liquefaction: put the material into the reaction kettle that fills the dilute sulfuric acid of 0.5% by volume percentage concentration, the mass ratio of material and acid water is 1: 2.5, promptly 100Kg material adds 250Kg. .5% dilute sulfuric acid, add the α-amylase of 2% of material weight and promptly add 2Kg α-amylase, α-amylase concentration 200,000 units / gram, heat, keep temperature 92 ℃, enzyme acid liquefaction 5 hours, make Get liquefied mash. (4) Filtration: filter to remove slag, take the filtrate, (5) vacuum concentration: the f...

Embodiment 2

[0031] Embodiment 2: The difference from Example 1 is that the process of making liquefied mash in step (3) is different, and other processes are the same: take the fresh corm of Lycoris as raw material, clean the silt with tap water at normal temperature, and grind the cleaned silt with a pulverizer. Lycoris balls are pulverized, put into a reaction kettle equipped with α-amylase solution, adjust the pH value to 4 with sulfuric acid, the mass ratio of material to water is 1:3, and the amount of α-amylase added is 2% by weight of material , the temperature is 55°C, and the enzymolysis time is 4 hours. After the enzymolysis, the temperature is raised to 92°C, the pH value is adjusted to 1 with sulfuric acid, and the acid hydrolysis is carried out for 2 hours to obtain liquefied mash. It is 156.48 kilograms of wine that alcohol concentration is 14.04% by the step of embodiment 1 (4) (5) (6) (7) (8) (9) again, containing 21.97 kilograms of ethanol, starch conversion rate 95.5%.

Embodiment 3

[0032] Embodiment 3: The difference from Example 1 is that the process of making liquefied mash in step (3) is different, and other processes are the same: take the fresh corm of Lycoris as raw material, clean the silt with tap water at normal temperature, and grind the cleaned silt with a grinder. Lycoris balls are crushed and put into a reaction kettle with a pH value of 1 sulfuric acid solution, the mass ratio of material to water is 1:3, the temperature is 95°C, acidolysis is carried out for 4 hours, and then the temperature is lowered to 55°C, and the amount added is The α-amylase with 2% weight of material, the enzymolysis time is 2 hours, and the liquefied mash is obtained. It is 165.70 kilograms of wine that alcohol concentration is 13.12% by the step of embodiment 1 (4) (5) (6) (7) (8) (9) again, containing 21.74 kilograms of ethanol, starch conversion rate 94.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com