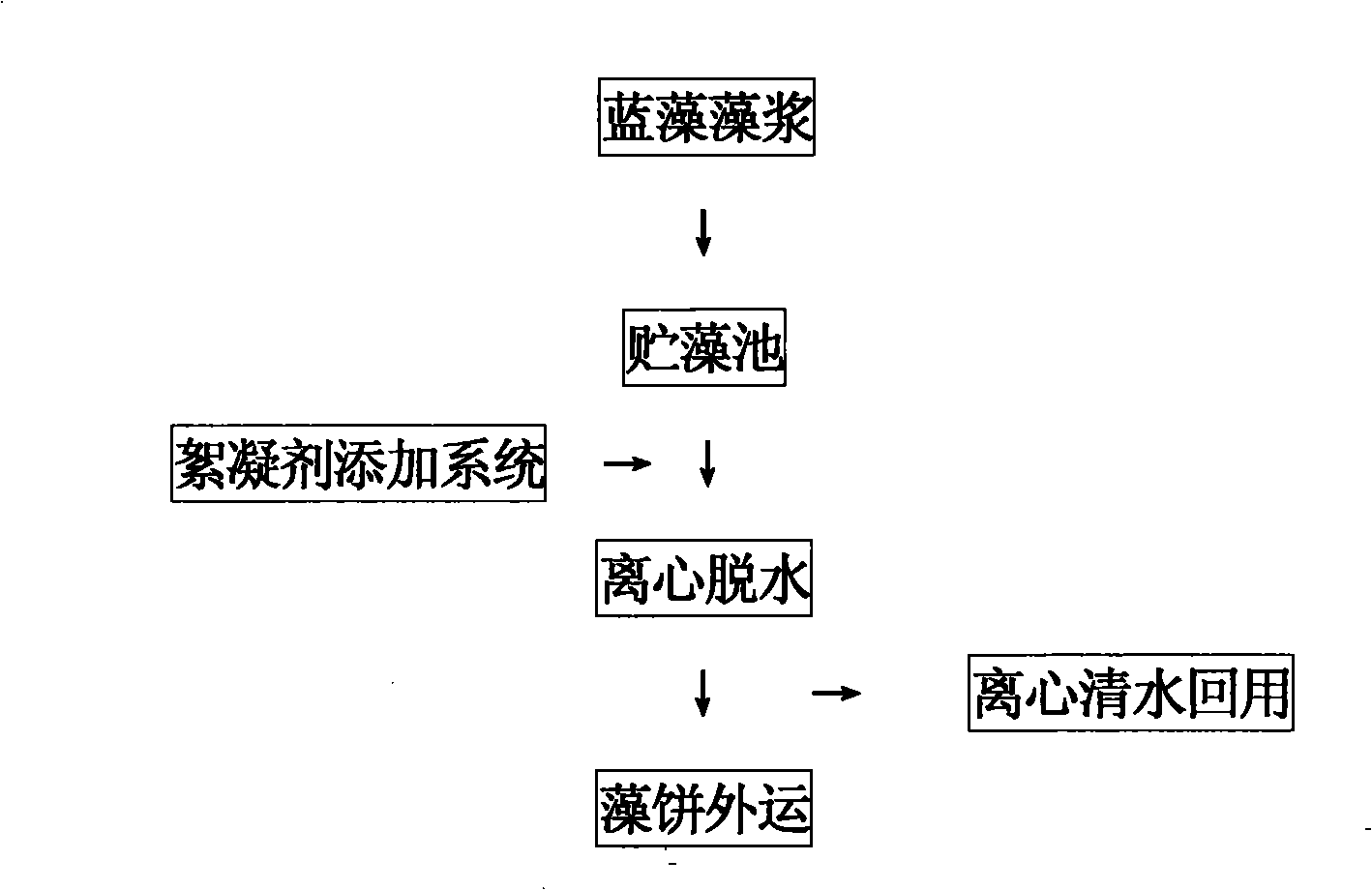

Blue algae slurry dewatering process method

A technology of cyanobacteria algae slurry and cyanobacteria slurry pump, which is applied in the direction of separation methods, chemical instruments and methods, and sediment separation by centrifugal force, which can solve the problems of odor emission, poor effect, and easy corruption, and achieve reliable operation and removal effect Obvious, low-investment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: process the cyanobacteria algae slurry that the output of Dianchi Lake is 100 tons / day, the water content of the cyanobacteria algae slurry is about 97-99%, and the sludge pump is pumped into the horizontal screw discharger that is sold in the market and has a processing capacity of 8 tons / hour. The material is dehydrated in a sedimentation centrifuge. Before the cyanobacteria pulp enters the horizontal screw discharge sedimentation centrifuge, 0.5ppm of cationic organic polymer flocculant is added in the way of pipeline dosing. After the horizontal spiral unloading sedimentation centrifuge is started, the suspension of cyanobacteria and algal pulp is fed into the spiral inner cylinder through the feed pipe, and then flows into the drum. Under the action of centrifugal force, the solid phase of cyanobacteria settles on the wall of the drum. The moisture content of the cake is 75%-90%, so that the liquid phase algae slurry becomes a semi-solid phase algae ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com